Welding - Campbellsport School District

advertisement

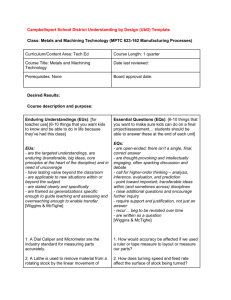

Campbellsport School District Understanding by Design (UbD) Template Class: Welding Technology Curriculum/Content Area: Tech Ed Course Length: 1 quarter Course Title: Welding Technology Date last reviewed: Prerequisites: None Board approval date: Desired Results: Course description and purpose: Enduring Understandings (EUs): [for teacher use] [6-10 things that you want kids to know and be able to do in life because they’ve had this class] EUs: - are the targeted understandings, are enduring (transferable, big ideas, core principles at the heart of the discipline) and in need of uncoverage - have lasting value beyond the classroom - are applicable to new situations within or beyond the subject - are stated clearly and specifically - are framed as generalizations specific enough to guide teaching and assessing and overreaching enough to enable transfer [Wiggins & McTighe] 1. Understanding blueprints and the symbols on those blueprints are important skill in the welding field. 2. Arc Welding is an important welding process used for the fabrication of steel structures and vehicles. Essential Questions (EQs): [6-10 things that you want to make sure kids can do on a final project/assessment… students should be able to answer these at the end of each unit] EQs: - are open-ended; there isn’t a single, final, correct answer - are thought-provoking and intellectually engaging, often sparking discussion and debate - call for higher-order thinking – analysis, inference, evaluation, and prediction - point toward important, transferable ideas within (and sometimes across) disciplines - raise additional questions and encourage further inquiry - require support and justification, not just an answer - recur… beg to be revisited over time - are written as a question [Wiggins & McTighe] 1. What is the importance of welding symbols on blueprints? 2. What variables would you make you choose the Arc welding process for a certain project? 3. MIG welding is the most popular industrial welding process due to speed and ease of use. 3. What variables would you make you choose the MIG welding process for a certain project? 4. TIG welding is a process used primarily for welding thin material such as stainless steel and other non-ferrous alloys. 4. What variables would you make you choose the TIG welding process for a certain project? 5. Plasma cutters are used to cut different thicknesses of material with high heat combined with high speed air. 5. What factors will affect the quality of cut on a plasma cutter? 6. Gas torches are used to cut thick material by combining Acetylene and Oxygen. 6. How does adding oxygen to Acetylene create a flame hot enough to cut metal? Assessment Evidence Performance assessments: Other assessments: Measuring and Blueprint Reading A. Basic Measuring B. Blueprint Reading C. Basic Lines and Views D. Symbols and Geometry Standards (CCSS, Next Generation Science, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: Arc Welding (SMAW) A. Butt Joint B. Edge Joint C. Lap Joint D. Tee Joint E. Corner Joint Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: MIG Welding (GMAC) A. Butt Joint B. Edge Joint C. Lap Joint D. Tee Joint E. Corner Joint Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: TIG Welding (GTAW) A. Butt Joint B. Edge Joint C. Lap Joint D. Tee Joint E. Corner Joint Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: Plasma and Oxy-Acetylene Cutting A. Safety B. Proper set-Up C. Material Thickness D. Cutting Speed Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: