Chemicals Management - Engineers Australia

advertisement

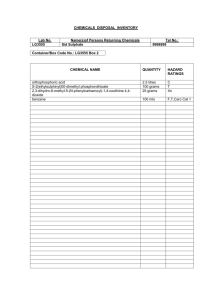

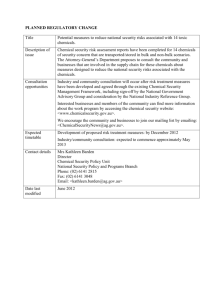

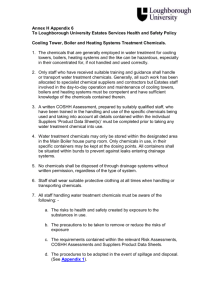

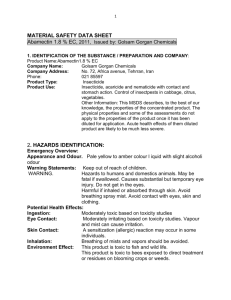

Chemicals Management: The Importance of Chemicals Management in Moving toward Sustainability Modern industrial practices and domestic lifestyles depend on the use of a wide range of chemicals. The United Nations Environment Programme estimates that there are about 100,000 manufactured chemical substances in use as well as thousands of substances of natural origin. Most of these are used in very small amounts as only about 1,500 chemicals account for over 95 percent of total world production. While best practice chemical use involves a high degree of safety, there is a need for considerably more work to be done to ensure that chemicals are used and managed in a manner that can be considered sustainable. Although chemicals generally undergo extensive testing before they are approved for use in Australia, some potential long-term effects of specific chemicals emerge only after these products have been use for many years. The effects, for example, of chlorofluorocarbons on the ozone layer were not foreseen until after the chemicals were widely used. More information is needed about many currently used chemicals before reliable risk assessments can be made. Safe disposal of chemicals, particularly those considered toxic, is essential to prevent future environmental damage. Precaution needs to be exercised in judging safety of disposal techniques because many of today's contaminated sites resulted from disposal methods considered safe at the time. Safety has to be ensured over a chemical's entire life cycle. Even though countries like Australia have well-established frameworks for managing chemicals, many developing countries lack the infrastructure to ensure that chemicals are used and managed safely. Problems are compounded by the export to developing countries of chemicals banned in industrialized countries. Such export violates international treaties. Engineers working in developing countries have to be particularly careful to ensure use of safe chemicals management methods in the absence of regulations, classification and labelling requirements, skilled workforces and other factors which lead to safe practices in Australia. In view of the limited knowledge about longterm effects of many chemicals and the difficulties and cost involved in safe use and disposal, considerable benefit can be obtained from the application of cleaner production techniques. Using such techniques, less harmful substances are substituted for substances of concern. Manufacturing processes can be redesigned to eliminate the problems caused by use and disposal of difficult substances. In the agricultural field, integrated pest management can reduce or eliminate dependence on toxic pesticides. Checklist for Improved Chemical Use Most workplaces meet the requirements for chemical use under the National Occupational Health and Safety Act and various State Acts and Regulations (such as Dangerous Goods). But many worksites can still improve their environmental performance by looking at chemical use from a waste management perspective. By following the waste management hierarchy below, you could help your company save money and reduce the environmental effects of its operation. Benefits of Improving Chemical Use reduced operating costs through reduced usage reduced worker exposure and risk of accidents through simplified chemical storage and handling reduced toxicity of your effluent, possibly reducing waste disposal charges reduced load on and upsets to wastewater treatment plant, particularly if biological Criteria for Judging the Environmental Effects of Chemicals If the chemical is imported, this information may already be available. If it isn't, ask your supplier; the more that suppliers are asked to provide environmental information, the more readily available the material will become. BOD (Biochemical Oxygen Demand) gives an indication of how much oxygen is required to oxidise the biodegradable portion of the product products with a very high BOD can lead to anaerobic conditions due to the high demand for oxygen. COD (Chemical Oxygen Demand) gives an indication of the `concentration' of the waste BOD/COD ratio the closer to one, the more biodegradable the contaminants in the effluent EC50 indicates concentration required to create toxic effect (higher values therefore better) Pow (Octanol Water Partitioning Coefficient) indicates how much of the product will enter the water column Concentration of key components Avoid or minimise the following: sulphides chlorinated hydrocarbons (found in solvents) these are persistent/ do not biodegrade generally, the more chlorinated the greater the environmental impact chlorinated aromatics are particularly problematical (especially polychlorinated biphenyls) metals, in the following order: tin (tributyl, found in plasticisers), silver, mercury, cadmium, lead, copper, beryllium, thallium, selenium, aluminium (in acidic environments), cyanide pesticides (aldrin, dieldrin, chlordane etc.) and herbicides (acrolein etc.) phthalate esters Minimising Waste from Chemical Use Avoid use modify process to remove need for chemical eg drip trays under leaky equipment, recycle product where possible improve housekeeping (eg replace pesticide use with planting of heatresistant low-growing native plant in fire danger areas, or manual removal/ controlled burning) Reduce/Reuse dilute chemical where possible (dial-in dispensers which mix with water at drum source) use less toxic chemical, as per above criteria (see examples on next page) check with guidelines for water reuse - is your waste stream a secondary resource? Can it be reused for lower grade uses? prevent rainwater ingress into storage area, to reduce volume requiring treatment store in 10qOL bulky boxes, rather than 20L drums to reduce handling waste disposal and improve control (automate?) improve control system by online monitoring to reduce use eg cooling water systems; biocide control reduces blowdown frequency, saves water, reduces disposal requirement Treat reduce toxicity before discharge Dispose the final choice when other options are exhausted Examples of Chemical Substitutions' Industry Chemical Use Alternative Printing Organic solvents Cleaning Vegetable oil Laboratories Acetone Glass drying All Methylene chlorine/ phenol (solvents) Paint removal Heat drying/ pneumatic drying Sand or garnet blasting/ alkali All Solvent Oil Paint carrier Paint carrier Silicate Waterborne Metal work Lubricant Vegetable oils/ soapy water All Petroleum products/ mineral oils Chlorinated Cleaning/ degreasing hydrocarbons Abrasion/ alkali/ soapy water/veg oil Manufacturing Adhesives Bonding Mechanical/ physical assembly/ hot melt Welding Polyurethane filler References 1. ANZECC, 1992, `Australian Water Quality Guidelines for Fresh and Marine Water', Canberra. 2. Numerous Worksafe Australia Publications (NOHSC 1008 (1994), 2011(1994), 3017 (1994) etc. Prepared by Tracey Colley Colley Consulting Pty. Ltd. for the Chemical College Board Institution ofEngineers, Australia Related Issues risk assessment precautionary principle cleaner production site remediation waste management water quality Case Study Henderson's Automotive Group, Melrose Park Plant (as part of Commonwealth Cleaner Production Dem onstration Program ) Method: Replaced oil based lubricant with water based lubricant Benefits: reduced worker dermatitis decreased frequency of waste disposal improved safety performance reduced costs better quality because of reduction in rust associated problems