chemical manufacture in runcorn and weston 1800 - 1930

advertisement

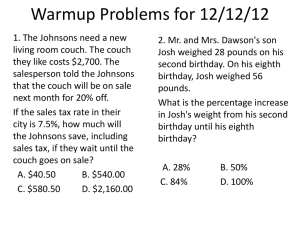

CHEMICAL MANUFACTURE IN RUNCORN AND WESTON 1800 - 1930 Gordon Rintoul January 1984 By 1800 the industrial transformation of Britain was well underway. The industrialization and urbanization of British society did not, however, occur overnight. Industrial development took place gradually rather than in a cataclysmic instant. In the early nineteenth century many areas of the country, although undergoing great changes, retained a measure of pre-industrial peace. The small town of Runcorn (pop. 1470 in 1800) was one such spot. Even inn the 1830's it was described as a healthy spa possessing large areas of parkland and clean air. Gradually, however, this situation began to change largely under the impetus of competition between the Duke of Bridgewater' Canal and the Mersey and Irwell Company and also a demand for stone from local quarries. In a few decades Runcorn had grown to become a bustling industrial town, possessing a population of 3000 in 1841 (1). In addition to its growth as a port and a centre for the transhipment of goods, the town gained several manufacturing industries: shipbuilding, tanning and chemicals. It is the story of the development of the most important of the latter type of works that this paper is concerned. While the importance of the Widnes area just across the Mersey as a centre of the alkali industry is well known, the development of the industry on the Runcorn side of the river remains obscure. Origins and Early Growth In 1798 the Rev Thomas Alcock, Vicar of Runcorn, bequeathed several parcels of land in the township of Runcorn, adjoining the Bridgewater Canal, to his niece Elizabeth Burton. Three years later she married John Johnson, a farmer residing in the Runcorn area (2). Johnson lost no time in increasing the value of his wife's inheritance. In 1803 he raised money by mortgaging the property, obtaining a loan of £800 from Thomas Pickering of Halton. This money was to be used for the erection of dwelling houses and for other improvements of the land. Four years later Johnson obtained two further mortgages of £500 each. By the time of Johnson's death at the early age of 37 in August 1816 the borrowed money had been invested in industrial development on the site, in addition to housing, As a consequence, the value of the land had grown considerably Five years after Johnson's death his wife was able to mortgage the property for £3,400, using part of this sum to pay off the original £1500 in loans (3). At this time the property is described in the Title Deeds as including a soap factory, ropeworks and a slate shop. The soapworks had been established by Johnson in the 1800s using the money raised in loans; in his will he described himself as being a soapboiler (4). By 1822, however, Messrs Hayes, Ollier and Company are described in the deeds as tenants of Johnson's wife and operating a soap, rosin and turpentine works. This firm had been in operation since at least 1821 (5). In 1823 the property was again re-mortgaged, this time for Z5000, out of which the £3,400 existing, mortgage was paid off. At this time the greater part of -the land was in the tenancy of Hayes, Ollier and Company (6). By 1828, however, a local directory was listing the firm of Johnson and Briddons as soapboilers and ropemakers and Thomas Johnson as a turpentine distiller (7). Thomas Johnson's sons, John and Thomas, were the owners of these works. Presumably what happened was that after Thomas Johnson's (the elder) death his factory was taken over by Hayes and Oilier before subsequently reverting to Johnson's sons soon after they came of age (8). The fact that Ralph Assager Hayes was one of the executors of Johnson's will may lend some support to this view (9). The Johnson's family business prospered and expanded during the 1830s. By 1832 enough had been earned to enable Elizabeth Johnson to repay some of the mortgage (10). This was a decade of expansion for the Merseyside soap industry. Before 1800 London was the main centre for soap manufacture. This pre-eminence was however, soon challenged by the growth of the industry in the Liverpool region. The latter area benefited from easy access to supplies of coal and a favourable location for the import and export of goods (12.). By 1834 Liverpool had overtaken London as the centre of the British soap trade and Runcorn had become the fifth largest soap manufacturing town in the country: Soap production in Britain 1834 Liverpool 52 million pounds London 34 " " Glasgow 8.6 “ “ Bristol 8.5 " Runcorn 7.5 " " " The extent of J and T Johnson's business can be judged by the amount of excise duty paid on soap produced. In 1832 they paid £38,681, making them the second largest soapmakers on Merseyside. Given the level at which soap was taxed one can infer that they produced about 1500 tons in 1832 rising to 2000 tons two years later (12). This expansion in output was a direct result of a repeal in 1833 of almost half the soap duty. This cut in tax was in part the result of extensive lobbying by the Association of Soap Manufacturers, of whom the Johnsons were members (13). By 1841 the Johnsons works had grown to such an extent that in the space of a decade their rateable value had tripled (14). In the 1830's the Johnsons expanded their business by taking over a soapworks at Weston. In 1833 Dennis Kennedy and Thomas Maguire, partners in a Liverpool soap manufacturers, purchased some land on the banks of the River Weaver at Weston, The following year, after taking out a mortgage of £1.000 from the Bankes family (who held extensive land in the area), they erected buildings, boilers, vats, etc (15). In the same year they are listed in Pigot's Cheshire Directory as Chemical Manufacturers (16). This signalled the beginning of the transformation of the Weston area. In 1840 it was recorded that the area "attracts a vast number of visitors in the summer season, from its being pleasantly situated near the rivers Weaver and Mersey" (17). Kennedy and Maguire's business did not, however, last long and in 1836 they defaulted on their mortgage. For the sum of £1,084 17s 6d, J and T Johnson purchased the land and plant and an additional piece of land alongside (18). In the same year the Works was described in a survey of the Merseyside area as being a Vitriol Works (19). This expansion onto an additional site laid the basis for a prosperous future for the Company. The Johnson's had not, however, been inactive at their original Runcorn site. By 1841 they were described as soap, turpentine, rope and alkali manufacturers (20). Three years previously they had erected a chimney over 200 feet high at their works (21). The presence of this high chimney coupled with their trade directory listing as alkali manufacturers strongly suggests that the Johnsons had begun to manufacture soda by the Leblanc process, the chimney being necessary to carry off the hydrochloric acid produced in the first stage of the process. At this time the Leblanc alkali industry was expanding in the region, particularly in nearby St Helens (22). Further, it is known that by the mid-1830's Leblanc alkali had to a significant extent replaced natural sources of alkali, such as help, in the Merseyside soap industry as a whole. (23) The Johnsons would certainly have been aware of the value of the process for their soap manufacture since they were present in 1838 when the Association of Soap Manufacturers raised the possibility, at their annual meeting, that "an improvement in the manufacture of soda, consequent upon the repeal of the salt duty" had made it easier for unscrupulous manufacturers to evade the soap tax. (24) If this supposition is correct then the Johnsons and not John Hutchinson were the first alkali manufacturers in the Runcorn and Widnes area. The Years of Enterprise In the 1840's John and Thomas Johnson built upon the foundations laid in the previous decade to establish a sizeable industrial and commercial empire. This not only involved increasing production at their Runcorn and Weston sites, but also the following of a strategy of 'vertical integration'. From manufacturing soap they expanded backwards into the manufacture of alkali and sulphuric acid and to secure supplies of the raw materials which they required: coal, salt, pyrites, and limestone. The Johnsons branched into the St Helens coal trade in the early 1840’s. Since the beginning of the nineteenth century the collieries around St Helens had been supplying coal in increasing quantities to the Cheshire saltmakers and by 1830 almost all the coal leaving the area was destined for that market (25). The following decade, however, saw a fundamental change in the market for St Helens coal. This was a result of the opening up of an entirely new market in the form of coal for steam powered ships. By 1846 the Secretary of the St Helens Canal and Railway Company estimated that of the 633,000 tons of coal extracted from the area, 183,000 tons were shipped to Cheshire Saltworks and 440,000 tons taken down the Mersey to Liverpool primarily for the use of steam boats (26). In order to meet these new demands a large increase in capacity of the coalfield was necessary. Over the period 1830-45 output was doubled with entirely new pits being sunk and old mines being extended (27). One part of the coalfield was particularly suitable to supply the steamboat market because its coal was of a high calorific value; this was the Rusty Park seam (28). John and Thomas Johnson began operating a coal mine on this seam at Laffack, to the north east of St Helens. Their business appears to have grown very rapidly since by 1843-44 they had succeeded in securing the coal contract for the navy at Liverpool (29). At this time this contract represented the largest single consignment of coal to naval establishments at home or abroad (30). By 1856 the Johnsons could claim to be producing over 150,000 tons of coal annually (31). Thus in a very short period of time the Johnsons had succeeded in moving into an entirely new line of business with very profitable results. This is only one example of the keen eye which the Johnsons possessed with regard to opportunities to make financial gains. in the 1840's J and T Johnson also expanded into the salt industry. With the process of industrialization and the expansion of population the Cheshire salt industry grew to attain enormous dimensions. In addition to the expansion of traditional markets the mid nineteenth century also saw the growth of a new large market for salt - the Leblanc alkali industry. It was perhaps in part to secure their own source of salt that the Johnson, branched out into the Cheshire saltfields. Although they are listed as having shipped salt down the River Weaver from Northwich in 1843, it appears to have been in 1845 that their main salt business began (32). On land leased from Lord Delamere at Over in the Winsford area, they erected warehouses, quays, steam engines, salt pans and bored a brine shaft (33). By 1856 the works was producing 20,000 tons of salt per annum (34). Obviously the Johnsons were not only producing salt for their own use but also for sale. Coal and salt were by no means the only areas into which J and T Johnson expanded. At some time before 1857 they secured sources of other raw materials for their chemical works by purchasing limestone quarries in Wales and pyrites mines in Ireland (35). By 1850 they had opened a shipyard near the old steam mills in Mill Street in Runcorn (36). They also began acquiring a large fleet of ships to transport their raw materials and finished products; in 1865 they possessed four schooners, one coasting flat, nine river flats, and four other boats (37). In addition to their industrial interests the Johnsons were also engaged in farming in the Runcorn -area in a substantial way (38). The creation of this commercial and industrial empire made the Johnson's extremely wealthy. In 1846 Elizabeth Johnson was able to repay in full the £4,500 owed on the mortgage on the Runcorn land (39). On his marriage in 1857 Thomas Johnson was living at Halton Grange, described in a local newspaper report as a "mansion". The same report recorded that the "firm of Thomas and Johnson (are) not merely of local standing they possess almost a world wide .reputation" (40). As the Johnson expanded the breadth of their industrial and commercial activities they also invested heavily in increasing the capacity of their Runcorn and Weston chemical works. In 1846 and again in 1858 they secured additional leases for land adjoining their Weston factory (41). Indeed, by 1850 one local directory was able to record that the Johnson's works "were extensive" (42). In the same year a very tall chimney reaching 360 feet was built at the Weston site (43). The aim of this chimney was to disperse the hydrochloric acid gas produced in the first stage of the Leblanc process. At this time the Johnsons passed the gas directly into the air without using condensing towers (44). The Weston site was an ideal situation for a chemical works. In 1860 an advertisement appeared in the Warrington Guardian for a large piece of land to be let on a long term lease: 'To Manufacturing Chemists and others. To be let on the bank of the Weaver.... Land is admirably adapted for manufacturing purposes.... Lying on the banks of the Weaver Canal; it communicates with the salt districts of Cheshire; being within a short distance of the St Helens Canal and Railway, it communicates with the coal districts of Lancashire The Weaver Canal, opening into the Mersey affords communications to Liverpool. The local rates are very low. Articles conveyed to and from the land along the canal are free from tolls.' (45) This illustrates just how important geographical position with respect to raw materials and the existence of a good transport system were to the siting of chemical works. Given this situation the Johnsons' decision to expand their Weston factory was thus a sound one. In 1859 a new works underwent construction at Weston alongside the Johnson's factory. These were established by William Collier who for 22 years had been the Johnson's Manager (46). Collier leased a parcel of land from the estate of the Bankes family for a period of sixty years at a rent of £160 per annum. In addition he agreed to erect buildings for the trade of manufacturing chemist and dwelling houses to the value of £80. These works were, however, only to be in Collier's hands for two and a half years. In April 1862 he sold up to the Johnsons for the sum of £3,500. In the intervening period he had erected buildings, chambers, vats, furnaces and steam engines (47). Collier, now a farmer, claimed before a Government Commission a few months later that he had been forced to give up his business because of a relentless campaign by the Johnsons. Collier had a lower chimney than the adjoining factory but condensed his hydrochloric acid efficiently. The Johnsons, however, refused to pay for damage caused by their fumes and were consequently taken before the County Court. Collier claimed that this incident led the Johnsons to persecute him, finally forcing him to sell up (48). Eventually Collier's works became known as the Weston No 2 Works. William Collier’s account of the unscrupulous nature of the Johnsons in relation to their business interests is borne out by their attitude to complaints about pollution from their Runcorn works. Until the 1863 Alkali Act the hydrochloric acid from the saltcake furnaces at these works was passed directly into the air (49). Even in the years following the Act the Johnsons continued to be frequent offenders. In mid 1866 the pollution from the works was very bad. Mr Blake, the Inspector of Nuisances for the Runcorn Highway and Sanitary Committee, reported that he had witnessed a dense cloud of vapour arise and descend from the works one evening. The following day he visited the scene to find vegetation damaged (50). Consequently Blake tried to get the Johnsons to take action. Two months later he addressed a letter to the Sanitary Committee stating that:- 'I lay before you a statement made to me by E Clarke Esq on the 9th inst. when in his office he said, "Blake, I would have you be very cautious, for if you would hear what Mr T Johnson has to say about you for sending these reports (I said what did he say), he said that Mr T Johnson made use of a great deal of harsh language. One expression made use of by Mr Johnson was that he would leave no means unturned to upset Blake from his position." ' (51) Evidently the Johnson's were not to be tangled with! As I outlined earlier' the Johnsons had continually expanded their activities and scale of operation during the 1840's and 1850's. At the end of the latter decade they secured the final link in the chain of their strategy of 'vertical integration'. In 1859 they purchased the Ironbridge oil works in Widnes for use as a factory refining rosin, an essential ingredient for soapmaking. These works, situated on the banks of the Sankey Canal at the north west corner of the ironbridge carrying the railway line onto 'Spike Island’, had been in operation since at least 1845 as an oilworks (52). The owner was, however, declared bankrupt in 1852 and after passing through the hands of several parties, the Johnsons purchased the land for £2,500 (53). At about the same time they also purchased patents enabling rosin to be distilled without decomposition. These were put into use at the Iron Bridge works to produce refined rosin for incorporation in the Johnson's pale yellow soaps (54). By the 1860s the Johnson's business empire was at, its height. They owned extensive chemical works in Runcorn and Weston for the manufacture of soap, soda, sulphuric acid. They could supply their own raw materials from a saltworks at Winsford, a coal mine at St Helens, limestone quarries in Wales, pyrites mines in Ireland and rosin from their works in Widnes. The Johnsons were not, however, simply the largest manufacturers in the Runcorn area, they were also heavily involved in the affairs of the local community. The Manufacturer as Public Figure With the Johnson's commercial prosperity came social standing and political power in the local area. Like many entrepreneurs elsewhere in the country, John and Thomas Johnson became deeply involved in the affairs of the local community. In the early nineteenth century local Government in Runcorn was in the hands a local Vestry. In 1832, however, following an outbreak of cholera in which sixteen people died, a Board of Health was formed (55). John Johnson, at this time already the joint owner of the largest chemical works in the area, was nominated as a member of the Board (56). In 1851 a committee representing prominent interests in the town began meeting to consider whether to press for the passing of an act of Parliament for the improvement of the town. In June the following year the Runcorn Improvement Act received Royal Assent. The Act empowered a Board of Commissioners to pave, light, watch, drain, cleanse and otherwise improve the town of Runcorn and also to provide it with sewers and a market (57). Most of the members of the local business community were involved in the Improvement Commissioners, including Thomas and John Johnson. The Johnsons were already active in providing a gas supply for the town. In 1837 an act of Parliament was passed which enabled a supply of gas to be provided for the town. The promoter of the act was the Runcorn Gas and Light Company. The act was repealed in 1847 and replaced by the Gas Works Clauses Act which consolidated legislation, constrained profits and so on (58). A new company, the Runcorn Gas Company, was formed to put the relief Act into action. John and Thomas Johnson were involved in both of these gas companies (59). The first meeting of the Runcorn Improvement Commissioners (RIC) took place on 1st November 1852 (60). One of the first actions taken by them was to consider proposals to establish a market. The events leading up to the opening of this market in an 'Italian Style' building in 1856 are illustrative of the position of the Johnsons in the local community. In February 1853 a market sub-committee of the RIC was formed, consisting of John and Thomas Johnson, John Linaker Wright (owner of a tannery), James Cowley and Philip White. The committee duly, shortlisted four possible sites for the market: Walkers Croft (Church Street), a garden in Church Street, The Sprinch and finally a house in Bridge Street owned by the Johnsons (61). The site chosen was the one belonging to the Johnsons, for which the RIC agreed to pay £1,800 (62). The choice of the Johnsons property had unintended consequences. Under the Improvement Act it was found that the Johnsons had disqualified themselves from acting as Commissioners (at least for that year) by selling property to the RIC. In February 1854 a special meeting had to be held to elect two Commissioners in their place (63). Plans for the market did not, however, go ahead smoothly. Although the RIC had agreed upon a site and the price to be paid for it, they still faced the problem of how they were going to pay the Johnsons for their land. In November 1854 a special meeting of the RIC was called "To consider the best means of raising the money to pay Messrs Johnson for the market land"; a subcommittee was then formed to consider the matter. The Johnsons, however, would have none of this delay and instructed their solicitor to write to the RIC threatening to file a Bill to compel the, Commissioners to act upon the contract. The following week a special meeting of the RIC was called at which it was decided that the purchase would be completed on the condition that the Johnsons fulfilled a promise already given to allow the Commissioners to pay £800 of the purchase price in the form of a mortgage (64). This decision was finally ratified in June 1855 and it was agreed that the loan would be at 5% interest (65). This episode illustrates the strong position the Johnsons held in the town: they were on the market subcommittee which opted for their site and even loaned the RIC some of the money with which to buy it. Their threat to take court action is a further indication of their abrasive approach to business matters. After being disqualified from serving as Commissioners in 1854 the Johnsons took no further extensive part in the RIC's work, although Thomas Johnson served again from late 1855 to early 1856 (66). In addition to their involvement with the local gas company and local Government, the Johnsons were also religious and educational patrons. They were largely responsible for the foundation of Holy Trinity Church in Runcorn in 1838 and contributed to the expenses of the curate. In conjunction with the Earl of, Ellesmere they were promoters of daily infant and Sunday schools in connection with the Church. They also supported Sunday schools at their works in Runcorn. Finally, they built and maintained Trinity Ragged Schools (67). Overall the impression one gains is that the Johnsons were ambitious hard-headed businessmen who were always looking for new ways to expand their business. They could also be ruthless, as their attitude to William Collier, the Inspector of nuisances and the RIC (when they failed to pay for the market land) shows. At the same time they possessed the philanthropic attitude common to many of their social position at this time. Crash and Boom In the early 1860’s it is clear that the Johnsons commanded a large, thriving and expanding business empire. In about 1860 they had opened an office in Liverpool, with Charles Wigg as their agent (68). This was an obvious move because of the American trade in alkali and salt and the Johnson's large business in steam coal (69). Within a few years, however, their commercial edifice was to begin crashing down around them. During the American Civil War the Johnson's saw an opportunity to realize a speedy and substantial profit by running the blockade then being mounted against the ports of the South They purchased a number of steamships for this purpose and one vessel succeeded in its journey, realizing over £170,000. Subsequently, however, disaster struck when all their vessels were lost in the naval battle at Charleston (70). This proved to be a heavy financial blow to the Johnsons since they had evidently sunk a great deal of capital into the venture. This affair led first to the flotation of the Johnson's company as a public concern and eventually to their bankruptcy. On 13 November 1865 a new company registered under the recently passed Companies Act came into being. This was the Runcorn Soap and Alkali Company and its stated aim was to purchase the land, buildings, plant, patents, etc belonging to T and J Johnson at Runcorn, Weston, Widnes and Winsford. The promoters of the company were Thomas Campbell (a Liverpool merchant), Francis Shand (also a Liverpool merchant) William, Keats (a Liverpool merchant and copper smelter), Peter Boult and John Higson (both Brokers in Liverpool), Neil Mathieson (Described as a Runcorn soap manufacturer), Charles Wigg, a Liverpool merchant who was the Johnson's agent. Wigg was appointed as Secretary to the company and the Johnsons allocated places on the Board of Directors. The price to be paid to the Johnsons for the transfer was £183,724, £80,000 of which was to be taken in shares in the new company. The first list of shareholders provides an insight into the financing of the enterprise. Interestingly, local alkali and soap manufacturers like Gossage, Hazlehurst, Neil Mathieson and Duncan McKechnie (described as foreman of Johnson's works) invested in the company (71): Number of Shares John Johnson Thomas Johnson Neil Mathieson Charles Wigg P S Boult J F Campbell Robert Daglish William Gossage John Higson William Hayes Charles Hazlehurst Thomas Hazlehurst William Keates Duncan McKechnie Roderick Rayner Lloyd Rayner Francis Shand W W Shand Samuel Withers Rudolf Zwilcherbart 1900 1650 175 250 500 270 150 30 500 250 100 100 50 25 50 72 600 500 500 500 Occupation Merchant “ Manufacturer Merchant Broker Merchant Ironfounder Manufacturer Broker Merchant “ “ “ Foreman of works Broker “ Merchant Broker “ Merchant The Johnsons appear to have been in financial trouble since at least 1865, at which time the deeds of the property owned by them were deposited with the Royal Bank of Liverpool as security for a loan. On 26 February 1869 their land adjoining the Bridgewater Canal (the original family inheritance totalling 27,283 sq yd) was finally transferred to the RSA Co under the terms of the agreement reached when the later company was formed. The price paid, £29,250, was not, however, transferred to the Johnsons but retained by the bank in part satisfaction of money owed to them. In May the same year the Johnson's remaining land was conveyed to the bank because of the "large sum of money" still owing to it. In December 1869 the Johnsons still owed the bank over £5000 (72). Presumably what had happened was that the Johnsons had borrowed large sums of money to finance their plan to run the American blockade. When this speculative venture failed they were forced to mortgage the land which they held freehold in order to pay their debts (73). The only parts of their business which the Johnsons kept were their coal mines at St Helens. On 31 December 1869 the Johnsons surrendered their coal leases to the Laffack and Garswood Collieries Co Ltd. The following May the Gerrard family of St Helens reserved the leases, thus giving the Johnsons the opportunity to make good their losses (74) The Secretary and Agent of the new colliery company was Charles Wigg, now operating from the Runcorn Soap and Alkali Company's offices in Water Street, Liverpool (75). The declining state of the Johnsons' finances is exhibited in the number of shares in the RSA Company which they held (76): Year John Johnson Thomas Johnson 1865 1866 1867 1868 1869 1870 1871 2000 shares 1900 1900 25 25 nil nil 2000 shares 1650 1650 1025 1025 25 nil The Johnson's financial position is also indicated by the attempt made by John Johnson to sell his house (Bank House) to the Runcorn Improvement Commissioners in 1869. A sub-committee of the Commissioners was formed to consider Johnson's offer to sell but it decided that the asking price was too high and the building would require a considerable outlay before it could be used for public purposes. Accordingly a General Meeting of the RIC formally declined the offer (77). In November 1871 the Johnsons were finally declared bankrupt under the terms of the Bankruptcy Act of 1869 (78). The following year the Johnson's last company, the Laffack and Garswood Collieries Co Ltd, went into liquidation (79). The brothers lived on, John dying in 1883, Thomas in 1884, but their commercial activities were at an end (80). The 1860's were a fortuitous time for the Runcorn Soap and Alkali Company to come into existence. The decade after 1865 saw a boom in the Leblanc industry which was to a large degree due to the ending of the American Civil War. The lifting of the blockade enabled exports to be resumed and also caused a rise in demand from the Lancashire textile industry. In Widnes this period witnessed the most intense burst of activity in the town's existence, with the tonnage of salt decomposed and coal consumed quadrupling (81). The Companies Act of 1862 (which consolidated a series of Acts from 1844) also played a role in this since it enabled limited liability companies like the Runcorn Soap and Alkali Company to come into being (82). During this period the Runcorn Soap and Alkali Company was one of the largest in the Widnes and Runcorn area. A comparison of their raw material usage, production and numbers of employees with that of the largest Widnes Works is instructive (c. 1869) (84): Salt consumed Pyrites consumed Limestone consumed Manganese Oxide consumed Coal consumed Alkali produced Bleaching Powder produced Employees Runcorn Soap and Alkali Co Runcorn Weston Gaskell-Deacon and Co Hutchinson Co and 3,000 17,000 15,000 3,500 10,000 8,000 3,000 16,900 19,000 - 16,500 13,000 23,000 - 3,700 2,500 16 000 50 000 50,000 7,000 20,000 30 000 - 58,050 32,500 - ? 450 500 3,700 3,000 500 Salt Decomposed (tons, weekly average) Runcorn Weston Total 1865 1866 1867 1868 1869 1870 1871 1872 na 90 90 na 45 na 125 125 250 225 225 na na na 325 na 285na 250 250 315 na 315 nana 370 na 410 375 1873 150 250 400 1874 180 250 430 1875 245 250 495 1876 250 250 500 1877 250 250 500 1878 250 320 600 1879 170 340 510 1880 240 330 570 1881 230 330 560 1882 250 217 467 1883 200 220 420 During this period the company broadened its range of products, eventually producing not only sulphuric acid, saltcake and alkali but also extending the scope of its operations into copper extraction by building a plant for this purpose at Weston (85). In the late 1860s and 1870s the extraction of copper from pyrites burnt in making sulphuric became an important part of the Leblanc industry and several manufacturers invested in copper extraction companies (86). The company also continued operating its saltworks and by the late 1870s it was equipped with 11 salt pans - a substantial number (87). In 1888, however, the works was sold to the newly formed Salt Union conglomerate for the sum of £32,000 (88). This made a great deal of sense since at this time the salt, industry was in a state of crisis and, as we shall see below, the Runcorn Soap and Alkali Company's own financial position was looking insecure. At some time in the 1870s or 1880s the firm also stopped producing soap; this was perhaps a reflection of the increasing competition within that industry which is illustrated by the introduction of mass advertising techniques by Lever (89). It was almost certainly in 1872 that soap production ceased at Runcorn. In this year there was a disastrous fire at the works when upwards of half was destroyed at a cost of £80,000 (90). The boom years of the alkali industry during the late 1860s and 1870s saw an enormous increase in the manufacture of a product which had played only a marginal role in the economics of the industry until this time. This commodity was bleaching powder. Since the late eighteenth century the bleaching properties of chlorine were well known. Although several methods were tried to utilize chlorine for bleaching it was bleaching powder, patented by Charles Tennant in 1798, which was ultimately the most successful. Initially chlorine had been manufactured by reacting salt, sulphuric acid and manganese dioxide in leaden stills. With the growth of the Leblanc process, however, a new method involving the reaction of hydrochloric acid and manganese, ore was introduced (91). At first only a small amount of the hydrochloric acid produced in the first stage of the Leblanc process was used for making bleaching powder. There was a persistent imbalance well past the middle of the century between the market for saltcake and that for bleaching powder or hydrochloric acid. Even in 1869 all alkali manufacturers in Widnes and Runcorn were running large quantities of acid to waste into the River Mersey (92). There were two main constraints on the further utilization of the hydrochloric acid. One lay simply in the market for the product. Although it had for decades been in great demand in textile industry for bleaching cloth, it was only with the opening up of an entirely new market in the paper industry that production increased significantly. In 1861 the excise duty on paper was abolished and esparto grass, straw and other materials began to be used. These required more bleaching than the rags formerly used (93). A second factor leading to increased demand for bleaching powder lay in a lowering of production cost and selling price. This was due to a. series of technological innovations first by Dunlop in 1845, then Weldon in 1866 and Deacon in 1868 (94). The result of all these factors was that output of bleaching powder rose from 47,000 tons in 1866 to about 130,000 tons in 1883 (95) . The production of bleaching powder by the Runcorn Soap and Alkali Company mirrored this national increase in output rising from 3700 tons in 1869 to about 7500 tons in 1833 (96). In the space of a few years, however, bleaching powder was to be elevated from its status as a profitable waste product to the mainstay of the Leblanc indu3try. By the mid 1880s the Leblanc alkali industry was in a state of crisis. In 1874 Brunner Mond had begun the manufacture of soda using the Solvay (or ammonia soda) process. Within a decade they had succeeded in making substantial inroads into the Leblanc firms’ alkali business. The reason for this was simple: Brunner Mond could produce soda at a much lower cost than the Leblanc manufacturers (97). In the face of this intense competition the Leblanc manufacturers increasingly relied upon bleaching powder as a source of profit. It was a sign of the state of the industry that in 1883 a Bleaching Powder Association was formed to fix prices and allocate production quotas (98). In addition, however, some Leblanc firms tried branching out into the Solvay process themselves. For example in the late 1880s Neil Mathieson and Co erected an ammonia soda plant at their works in Widnes to exploit the patents of a Viennese chemist Josef Hawliczek and by 1890 this plant had a capacity of 15,000 tons (99). Sometime before 1887 the Runcorn Soap and Alkali Company decided to attempt to enter the ammonia soda alkali business. The plant which they erected was based upon two patents taken out in the name of Charles Wigg, the Company Secretary and General Manager (100). Construction of the plant began in 1888 and it was in operation by October of that year (101). Considerable problems were encountered in getting the plant fully and efficiently operational. In 1889 the Chemical Trades Journal devoted a critical editorial to the subject, stating that 'At the end of 1887 directors were sanguine of success…… and now, after spending…… £9,000 they are still hopeful’ (102) They then suggested that the firm call. in experts to help them! Largely as a result of this investment the company's profits, dropped from £32,695 in 1887, £19,000 in 1888 and £963 in 1889 (103). The plant had a capacity of at least 60 tons per week. Production costs can be gauged by the extract below (60 tons produced) (104): Ammonia Fuel Salt: Common Rock Limestone Coke Water Casks Wages: Manufacture Repairs Freight, tonnage, etc General expenses Liverpool expenses Balance as profit 1072 lb 162 tons 97 tons 5 tons 105 tons 22 tons 249 gallons £ s d 16 41 32 18 26 8 7 22 55 17 4 13 5 17 1 8 14 9 5 10 5 10 10 5 10 15 5 6 9 4 9 6 3 7 3 10 290 - - As indicated above, the plant was not a resounding success. In the week ending Oct 5 1888 a loss of £130 15s 8d was made, the following week a profit of £l7 6s 10d and the next week a loss of £7 12s. The crucial factor appears to have been the percentage of ammonia lost in the process. Apart from the problems experienced in transferring the process to an industrial scale the venture. Alas almost doomed to be a failure because of its unfavourable location, since brine had to be made up from salt transported from the Cheshire saltfield. Sir Frederick Norman recalled that it was 'a project doubly damned alike as regards site, brine supply, disposal of effluent and every other conceivable drawback .... The story of the rascality and incompetence that marked this episode is a black one.... ' (105) The Beginning of the End On 1st November 1890 the foundations were laid for fundamental changes inn the Leblanc alkali industry. On this date the United Alkali Company was formed with powers to acquire a total of forty eight works. The rationale for this huge merger lay in the increasing competition which the Leblanc manufacturers were facing from the ammonia soda process. In addition7 the unwieldy nature of the fully developed Leblanc process made it almost impossible for manufacturers to cope efficiently with the changing pattern of demand for its range of products (106). Joint action was not unheard of in the Leblanc industry - many manufacturers had combined to oppose the 1863 and 1881 Alkali Acts and, as noted earlier, had met regularly to fix the price and production of bleaching powder in the 1880's. The Runcorn Soap and Alkali Company formed part of the United Alkali Company merger. The agreement to sell the company's assets to the UAC was signed on the 17th October 1890, the resolution to officially transfer the assets being passed at an Extraordinary General Meeting on 30th January 1891. A total of £325,000 was paid for the company, including freehold land in Runcorn, Weston and Widnes (107). Charles Wigg the Company's General Manager attained a key position within the UAC. In the Prospectus issued February 1891 he appeared as a Director and Vice Chairman of the Company (108). At its first meeting on 31 October 1890 the UAC Board of Directors appointed several committees. One of these was the Prospectus Committee which was to issue the Prospectus and receive applications for shares (except on the East Coast). Another was the Selling and General Purposes Committee whose function was to superintend selling, buying and other general matters. This latter committee was the real centre of power in the company, setting the selling prices for products. Charles Wigg was a member of both these committees and was thus in a position of some power and influence in the company (109). When the UAC was formed the Leblanc industry was in a dire economic condition. Further, the company was saddled with large quantities of near derelict, obsolete and unprofitable plant. Accordingly, they immediately began to set about making plans for rationalizing their production and concentrating it on fewer sites (110). When the Runcorn Soap and Alkali Company became part of the UAC it operated a wide range of processes. At its Runcorn works it had capacity for making saltcake using hand worked furnaces and also the Hargreaves--Robinson process, bleaching powder, soda ash, soda crystals and 'an ammonia soda plant. At the Weston Works sulphuric acid, saltcake, soda ash, bleaching powder, copper extraction and sulphur recovery plants were operated (111). Within a few years, however, the company's processes began to be shut down as a result of the UAC's wider strategy of rationalization. In 1895 bleaching powder production was halted at both sites, the following year production of saltcake was stopped at the Runcorn Works (112). The Chance sulphur recovery plant at Weston, which had been installed in 1889 as part of a more widespread attempt by Leblanc firms to cut costs, was transferred to St Helens at about the same time (113). Some new plant was, however, also installed. As noted earlier the UAC did not only close obsolete or unprofitable plant, it also concentrated production of particular chemicals on a ,mall number of sites. The Weston Works appears to have been chosen as a centre for the production of sulphuric acid: in the period 1906-11 over £12,200 was spent on new sulphuric acid plant and an associated de-arsenicating plant. Evidently Charles Wigg’s position within the UAC either did not enable him to act on behalf of his former works or he subsumed any personal interest to the wider corporate interests (115). At the turn of, the century further decisions were made by the UAC to restrict production at Runcorn and Weston. The Runcorn works appears to have been more or less closed entirely by the turn of the century, although it has been recorded that the works finally closed in 1923 (116). The Weston site, however, continued to concentrate on sulphuric acid, with saltcake and hydrochloric acid production being continued at a, steady but low level. The Works Manager at the time recalled that in the First World War Weston Works was reputed to be one of the largest Sulphuric acid works in the country (117). The works continued producing sulphuric acid, saltcake and hydrochloric acid until at least 1926 (118). At some time in the period 1926 - 1931 production finally ceased, certainly the works were closed by February 1932 (119). At this time both the Weston and Runcorn Works passed into the control of Castner-Kellner Works. The Weston Works was almost immediately demolished. The Runcorn Works were looked after by two pensioners and a watchman, the remaining buildings being let out to small businesses or as garages, although the soda shed was thought to be in such a dangerous condition that demolition was necessary (120). Thus came the final end for the alkali works at Runcorn and Weston. In 1930s however, a new chapter in the story of the industry was begun at, Weston with the building of a Ministry of Supply factory for the electrolysis of brine. This factory is now the Rocksavage Works of ICI. This history of chemical manufacture at Runcorn and Weston has covered a wide range of topics. From its beginnings in the soapery of John Johnson in the 1800s, to the vast commercial empire built by his sons, to their eventual demise through speculation on the American Civil War, to the flotation of the Runcorn Soap and Alkali Company and the reign of Charles Wigg, finally to absorption by the UAC, decline and finally demise under ICI. There are several points of note arising from this discussion; firstly the evidence presented represents what in some respects a reinterpretation of the history of the chemical industry on the Runcorn side of the river: John Johnson's was the first chemical works in the area, his sons, not Hutchinson were the first Leblanc manufacturers in Widnes or Runcorn. The importance of the works on the Runcorn side needs reappraisal: the Runcorn Soap and Alkali Company's works were as big, if not bigger than the largest in Widnes; the Johnson's business empire was larger than anything emanating from the Widnes side. NOTES 1) Starkey: 1981, Chap 2, 3 2) Title Deeds, Runcorn Soap and Alkali Co hereafter abbreviated to 'Deeds') CCRO D3075/20 3) Deeds 4) Barker, Harris: 1954, 230 5) (Nickson: 1888, 163). The firm is listed in Pigot’s Directory of 1822-23 as operating a soap, rosin and turpentine works. 6) Deeds 7) Pigot’s Cheshire Directory 1828 -29, 50 8) John Johnson was born 13 Jan 1800, Thomas on 4 Sept 1803; memorial inscription Runcorn Churchyard 9) Will of Thomas Johnson (proved at Chester 10 Feb 1817) 10) Ditto 11) (Musson: 1965: 7: 13-14, 41-42) 12) Seventeenth Report of the Commissioners of Inquiry into the Excise Establishment Vol. 5: Soap (1836). The largest firm, Matthew Steele and Co paid £40,300 in duty in 1832. In comparison, the other Runcorn soap firm, Hazlehursts, paid £22,985 in duty in 1832 and increased production during 1832-34 from 910 tons to 1260 tons. By 1852 total Runcorn soap production had grown to 5,262 tons (Poole, 25) 13) (Association of Soap Manufacturers: 1838). The cut in duty in 1833 led to a drop of about one third in the price of soap, Ibid, 5. 14) (Nickson: 1887, 185) 15) Deeds 16) Pigot’s Directory 1834 17) Robson’s Commercial Directory 1841 18) Deeds 19) (Boult: 1869, 203) 20) Robson’s Commercial Directory 1841 21) (Nickson: 1887, 165) 22) (Barker, Harris: l954) 23) (Barker, Dickinson, Hardie: 1956, 1.70) 2q.) (Association of Soap Manufacturers: 1838, 8). They were of course referring to the Leblanc process. 25) (Barker, Harris: 19 4 193) 26) Ibid, 115 27) Ibid, 197 28) Ibid, 194 29) Ibid, 197 (Challinor: 1972, 63) 30) (Barker, Harris: 1954, 194). In the period 1840-43 the contract had been held by the firm of Bromilow and Sothern who had supplied about 160,000 tons of coal per year. 31) Select Committee on Local Charges Upon Shipping, evidence of Thomas Johnson. By 1850 Bagshaw’s Gazeteer could list J. and T. Johnson as Coal Proprietors and Merchants. 32) (Calvert: 1915, 689, 612) 33) Records of the Runcorn Soap and Alkali Co. Ltd. Public Records Office. (hereafter RSA records). 34) Select Committee on Local Charges Upon Shipping evidence of Thomas Johnson Q.735. In 1850 the Johnsons began to be listed in local trade directories as Salt Merchants, Bagshaw’s Gazeteer 1850 35) Warrington Guardian 14/2/1857 36) (Nickson: 1887, 167), Bagshaw's Gazeteer 1850 37) R.S.A. records. 38) The Warrington Guardian 5/12/1857 records as a sale by auction at Halton Grange, home of Thomas Johnson, of 300 sheep and 74 cattle - this was a yearly sale. 39) Deeds. 40) Warrington Guardian 14/2/1857 41) Deeds. 42) Bagshaw's Gazeteer 1850 43) ICI Records, DIC/X10/2_31. The chimney was built by J. White of Runcorn using hand-made bricks. The external diameter was 30ft. 9in. at the base and 18ft. 3in. 300 ft. up. The wall thickness was 4ft. 9 in. at the base and 2ft. 4in. 300 ft. up. The height was successively reduced by 20 foot portions to 300 ft., when it was demolished on 6th Jan., 1932. At the time of demolition it was estimated that the chimney contained over 1 million bricks weighing over 4,100 tons. 44) Evidence of William Collier (former Works Manager) to R.C.N.V. 1878, Q.1102. 45) Warrington Guardian 4/2/1860. 46) Previous to that he had been employed at James Muspratt's Newton. Works for four years; evidence of W Collier S.C.N.V. (1862), Q742, 743. 47) Deeds 48) Evidence to S.C.N.V. Q749-58. 49) Ibid, Q762. 50) Runcorn Improvement Commissioners, Health and Sanitary Committee Minutes, 11/5/1866. 51) Ibid 16/7/1866. 52) (Dickinson: 1952). Slater’s Directory of 1848 lists the works as Patrick Hayes, Oil Merchants and Refiners. 53) Deeds. 54) 'Edward Hunt 1830-84' J. Chem. Soc. (1884). Hunt was the co-author of one of the patents. The patents were: Edward Hunt and Henry Davis Pochin: 'Improvements in the treatment and applications of rosin and rosinous substances' (1858); Rudolph Bodmer 'Improved rosin and rosinous substances’ (1859); and the interests of Hunt and Pochin in patents in the U.S.A. and other countries. In 1864 the Johnsons took out a patent under their own name: purifying rosin and rosinous substances' (RSA records). 55) (Starkey 56) (Nickson: 1889, 186) 57) (Handley: 1902) 58) (Richardson; 1981, 176) 59) (Nickson: 1887, 188) 60) R.I.C. Minutes, vol. 1, 1st Nov., 1852 61) Ibid, 14/2/1853 62) Ibid, 28/11/1853. The contract was finally signed on 6th Feb. 1854 63) Ibid, 20/2/1854. For a report see Warrington Guardian 25/2/1854 64) Ibid 20/11/1854, 14/12/1854. 65) Ibid 25/1/1855. 66) Ibid 3/12/1855. He resigned on 4/2/1856. 67) Liverpool Daily Post 26/10/1883; Warrington Guardian 14/2/1857; (Nickson 1888, 207); (Trinity Church Centenary Souvenir: 1938). Thomas Johnson was Trinity Church Warden 1845-49. In his evidence to the Select Committee on Local Charges Upon Shipping (1856) John Johnson stated that he was connected with six schools, Q760. 68) Liverpool Trade Directories. For over a decade Wigg had been resident in Liverpool as a merchant 69) Liverpool Daily Post: 26/10/1883; (Barker, Harris: 1954). In 1856 John Johnson stated that he shipped nearly 20,000 tons of salt to America, (Select Committee on Local Charges Upon Shipping), this was shipped at low cost as ballast, Q775, Q778. 1983, 129) 70) "Death of a Runcorn Worthy" (obituary of John Johnson) Liverpool Daily Post 26/10/71883, CTJ Vol. 30 (1902), 529. 71) "Memorandum and Articles of Association", "Summary of Capital and Shares, 23rd May, 1866” R.S.A. Records.. 72) Deeds. The Royal Bank of Liverpool had actually gone into liquidation on 22nd Nov., 1867. It is unclear whether this event had anything to do with the Johnson's predicament. The liquidators may have for example called in the Johnson's loan. 73) Rather oddly the Johnsons were still active in expanding their operations in the mid 1860's. In 1865 and 1865 they purchased more land in Runcorn (paying £5,500) and Weston, (Deeds). Thomas Johnson also attempted to form a limited liability company with the Oldbury Alkali Company to extract copper from burnt ore (presumably by Henderson's wet process, in 1868. This venture did not come to fruition (Chance: 1919, 208). 74) Information from J.C. Barker contained in letters to R. Dickinson 15/8/1951, 4/6/1953 C.C.R.O D3075/20. 75) Liverpool Trade Directory. 76) Information abstracted from various conies of "Summary of Capital and Shares", R.S.A. records. 77) R.I.C Minutes. 7/6/1869, 1/7/1869, 3/7/1869, 5/7/1869. 78) London Gazette 20/10/1871, p.4326; 24/10/1871, p4369; 21/5/1872, p.2467. 79) Information contained in a letter from T.C. Barker to R. Dickinson 4/6/1953. C.C.R.O. 03075/20 80) Information on dates of death from monumental inscription, Runcorn Churchyard. 81) (Hardie: 1950, 64) 82) (Warren: 1981, 886) 83) Rivers Pollution Commission (Evidence - Answers to Queries). In 18'73 in his evidence for the Sheffield and Midland Railway Companies Bill, Charles Wigg, the R.S.A. Co. secretary, claimed that a total of 300,000 tons of raw materials and products were loaded and unloaded at the Weston works, this would seem to be quite untrue. Sheffield and Midland Railway Companies Bill: 1813. 84) Compiled from Annual Reports of the Alkali Inspector. Individual firms are only identified by number in the Reports. The relevant numbers were kindly provided by Mr. Tunnicliffe, Deputy Chief Industrial Air Pollution Inspector. 85) Plan of Works, undated. ICI Archives DIX/X10/231 86) See (Checkland: 1967) 87) (Calvert: 1915, 535) 88) (Calvert: 1913, 7) 89) See (Wilson: 1954, Vol. 1) 90) CTJ Vol. 1 (1887), 119. 91) See (Mond: 1896) for a useful account of the development of plant for manufacturing chlorine 92) Evidence (Answers to Queries) Rivers Pollution Commission. 93) (Higgins: 1924, 70) Esparto grass was first used by the Tyneside papermaker Thomas Routledge in 1861 (Warren: 19819 122) 94) (Mond: 1896), (Hardie: 1951, 1955). 95) (Huber: 1958, 5g, l52)a 96) Evidence (Answers to Queries) Rivers Pollution Commission; (Report of the Alkali Inspector: 1883) 97) (Hardie: 1950, 135-38), (Warren: 1981, 103-20). For a contemporary view of the threat posed to the Leblanc manufacturers see the spirited defence of them. (Weldon: 1883). 98) (Warren: 1981, 148) 99) (Dickinson: 1955, 181). 100) These were for the recovery of ammonia from ammonium chloride (BP 10295, July 1887) and for the manufacture of sodium bicarbonate (BP 9227, June, 1887) Wigg was not a chemist so it must be assumed that the processes were developed in the companies laboratory and taken out in Wigg's name as a representative of the company 101) CTJ Vol. 2 (1888), 1; in ICI Archives there is a balance sheet for the plant dated 12/10/1888 (DIC/X10/233) 102) CTJ Vol. 4 (1889), 97-98. Similar difficulties had been encountered by Brunner and Mond in starting up their plant. 103) CTJ Vol. 2 (1888), 1; Vol. 4(1889), 17-18; Vol. 6 (1890), 108 104) Balance sheet for Runcorn Works week ending 12/10/1888, ICI Archives DIC/X10/233 105) (Norman: 1931, 44) 106) On the UAC see (Hardie: 1950, Chap. 9), (Warren: 1981 Chap. 13), (Kudo: 1977). 107) RSA records; Deeds; ICI Archives DIC/UA1/1. The purchase price was paid in the standard way for all the works: Fully paid-up ordinary shares: 40.86% 14.24% preference 11.78% debenture 37.07% In Cash 108) His son G.L. Wigg was also a Director, ICI Archives DIC/UA1/1 109) (Kudo: 1977, 12) 110) (Warren: 1981, 153-54) 111) (Davidson 1932, appendix) These details are taken from an inventory of all works compiled 1891, probably to help enable the company to decide which plants to close. 112) The following figures (per 1 year) give an idea of the size of the plant shutdown at Runcorn: Saltcake (tons) Bleaching Powder (tons) 1890 na 1394 1891 na na 1892 3574 na 1893 1334 817 1894 3044 na 1895 3437 closed 1896 closed closed 113) (Norman: 1931, 5) On sulphur recovery in general see for example (Checkland: 1967, 145-150). The sulphur recovery plant at Weston was built in Autumn, 1889, ICI Archives DIC/BM20/228 114) ICI. Archives DIC/UA101 115) Wigg died on 18th July, 1899, leaving a small fortune of £115,131 6s. His passing is symbolic of the passing of the Leblanc industry itself; see Liverpool Courier 19/7/1899, 27/7/1899 for reports of his death and funeral; the value of his estate is given in his will, proved at Chester 116) (UAC: 7_93-9, 77). There appear to be no other records about the closure. 117) Interview with Mr. F Maddock, October 1952 (probably by R. Dickinson), ICI Archives DIC/X10/233 118) ICI Archives DIC/UA5/6 119) Fred Maddock, the last works manager recalled that closure came in 1931, ICI Archives DIC/X10/233 elsewhere it is recorded that it came in 1927 (UAC: 1939, 77). 120) Castner Kellner works ref: LT/10, minutes 150, 207, 903; ICI Archives DIC/X10/231, 233 BIBLIOGRAPHY Local Trade Directories Bagshaw, S History, Gazateer and Directory of the County Palatine of Chester Pigot & Co. Robson & Co. Slater, J Cheshire Directory 1822-23, 1828-29, 1834 Commercial Directory 1841 Directory 1848 Government Reports Annual Reports of the Alkali Inspector 1864-1900 Report of the Commissioners Appointed in 1868 to Inquire into the best means of Preventing the Pollution of the Rivers Ribble and Mersey Basins Parliamentary Papers Vol. XL (1870) Royal Commission on Noxious Vapours Parliamentary Papers Vol. XLIV (1878) Select Committee on Local Charges Upon Shipping Parliamentary Papers Vol. XII (1856) Select Committee on Noxious Vapours (House of Lords) Parliamentary Papers Vol. XIV (1862) Seventeenth Report of the Commissioners of Inquiry into the excise establishment (soap) Parliamentary Papers Vol. XXVI (1836) NEWSPAPERS AND JOURNALS Chemical Trades Journal Vol.1 (1887) Vol.2 (1888) Vol.4 (1888) Vol.6 (1890) Vol.30 (1902) 119 1 17-18, 97-98 108 529 Journal of the Chemical Society (1884) Liverpool Courier 19/7/1899 27/7/1899. Liverpool Daily Post 26/10/1883 London Gazette 20/10/1871, p.4325; 24/10/1871, p.6369; 21/5872, p.2467. Warrington-Guardian 25/2/1854; 14/2/1857; 5/12/1857; 4/2/1860. Unpublished Sources ICI Archives: DIC/UAl1/1 DIC UA5/6 DIC/UA10/1 DIC/BM20/228 DIC/X10/231-237 United Alkali Co. Prospectus and Memorandum of Association Statistics of Annual Production and Sales Register of Expenditure Upon Purchase of Land and Extensions to plant Reports of Visits to inspect the progress of the erection of Chance sulphur recovery plants by various alkali manufacturers Misc. information relating to Runcorn Soap and Alkali Co. Ltd. Papers of Drs. Dickinson, Cheshire County Records Office, D3075/20 (T. and J. Johnson) Runcorn Improvement Commissioners, Health and Sanitary Committee Minutes, Cheshire County Records Office, Runcorn Soap and Alkali Co Ltd. Records Public Records Office BT31 1181/2590c