Control of Dangerous Substances and

advertisement

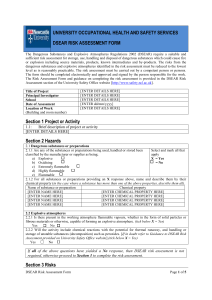

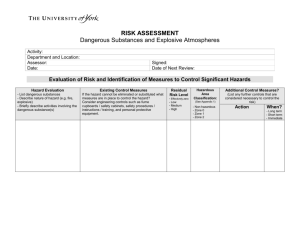

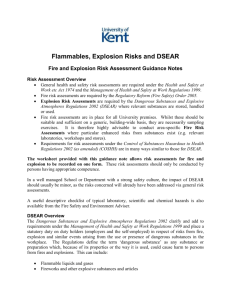

School of Life Sciences 1.0 LOCAL RULES FOR THE CONTROL OF DANGEROUS SUBSTANCES AND EXPLOSIVE ATMOSPHERES R3 INTRODUCTION The School of Life Sciences has developed these Local Rules to control the risks to staff, students, visitors and others who may be affected by the work activities of the School from dangerous substances which may cause fire and/or explosion and to ensure compliance with the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR). The key requirements of the regulations are: 2.0 that risks from dangerous substances are assessed and eliminated or reduced; places where explosive atmospheres may occur are classified into zones which are clearly marked out where required; equipment and procedures are provided to deal with accidents and emergencies. DEFINITIONS “Dangerous substances” as defined by DSEAR include substances, preparations and dusts with the potential to give rise to fires, explosions and similar energy releasing events which could cause harm to people. Dangerous substances include petrol, liquefied petroleum gas (LPG), paints, varnishes, solvents and certain dusts which, when mixed with air, could cause an explosive atmosphere. Such substances or preparations may be classified under the Chemicals (Hazard Information and Packaging for Supply) Regulations (CHIP) as: explosive, oxidising, extremely flammable, highly flammable or flammable. “Explosive atmospheres” are defined by the Regulations as an accumulation of gas, mist, dust or vapour, mixed with air, which has the potential to ignite or explode. An explosive atmosphere does not always result in an explosion but if it ignited, the flames would quickly travel through it and if this happened in a confined space (e.g. in plant or equipment) the rapid spread of the flames or rise in pressure could result in an explosion. Examples of activities/substances to which DSEAR apply: Storage of petrol as a fuel; Use of flammable gases, such as acetylene, for welding; Hot work on tanks or drums that have contained flammable material; Storage, use and handling of flammable substances such as solvents and gases Transport of flammable liquids around the workplace 3.0 IMPLEMENTATION Heads of Department are responsible for the implementation of these Rules within their area of control. Principal Investigators are responsible for the implementation of effective risk assessment and safe systems of work for activities under their control. Those involved in the assessments must be familiar with the requirements of DSEAR , the associated Approved Codes of Practice and these School Rules. They should know where to obtain information on dangerous substances, how they are used and stored, what control measures are necessary and when to consult others for help and advice. Issued: 20th July 2006 Page 1 of 6 Rev 1.0 School of Life Sciences LOCAL RULES FOR THE CONTROL OF DANGEROUS SUBSTANCES AND EXPLOSIVE ATMOSPHERES R3 Heads of Departments, assisted by the School Safety Adviser, must satisfy themselves that DSEAR assessments are Completed; Consistent and to a reasonable standard; Relate to the actual work being undertaken; Recorded and where appropriate proper records maintained; Reviewed and updated as required. Staff and students must cooperate with their Head of Department in making assessments. They must make full and proper use of any safe system of work, and/or prescribed control measures, reporting any defects and where appropriate participate in any monitoring. They must also participate in training and make full use of information and instructions. 4.0 ARRANGEMENTS The key steps to the arrangements are: Step 1 - Check whether a substance or preparation has been classified under the Chemicals (Hazard Information and Packaging for Supply) Regulations (CHIP) as: explosive, oxidising, extremely flammable, highly flammable or flammable. Step 2 - Assess the physical and chemical properties of the substance or preparation and the work processes involved to see whether the work activity creates a potential for fire, explosion or similar energetic (energy releasing) event. Step 3 - Check to see if the work activity involves the creation or handling of potentially combustible or explosive dusts. Step 4 – Carry out a risk assessment of any work activities involving dangerous substances. Record the findings of the risk assessment – including how they are used and who might be affected. Step 5 – Provide controls to eliminate or reduce risks as far as is reasonably practicable. Ensure the controls are implemented and maintained. Step 6 - Provide appropriate information, instruction and training about the risks and the precautions to be taken. Step 7 – Classify places where explosive atmospheres may occur into zones and mark the zones where necessary Step 8 – Set a date for review of the risk assessment. 5.0 ASSESSMENT In its simplest terms the risk assessment is an identification and careful examination of the dangerous substances present or liable to be present in the workplace; the work activities involving them; any existing controls, and how they might fail and cause fire, explosion or similar events that could harm staff and/or others and then deciding on any further action needed to remove or reduce those risks. Issued: 20th July 2006 Page 2 of 6 Rev 1.0 School of Life Sciences LOCAL RULES FOR THE CONTROL OF DANGEROUS SUBSTANCES AND EXPLOSIVE ATMOSPHERES R3 The assessment should take account of such matters as: the hazardous properties of the substances; the way they are used or stored; the possibility of explosive atmospheres occurring; all potential ignition sources. A risk assessment should be carried out regardless of the quantity of dangerous substance present, as it will enable a decision on whether existing control measures are sufficient or whether any additional controls or precautions are necessary. As well as assessing the normal activities within the workplace, the assessment should address non-routine activities, such as maintenance work. The significant findings of the risk assessment must be recorded. In practice all but the simplest assessment will need to be recorded. If an assessment has already been carried out under the Control of Substances Hazardous to Health Regulations, then there is no need to repeat it, provided that the assessment has already considered the potentially explosive, oxidising or flammable nature of the substance or dust. Although in many circumstances it will be necessary to obtain the Material Safety Data Sheet (MSDS) to obtain essential information for particular substances, the MSDS alone does not constitute an assessment. The assessment must consider many aspects but in particular, how the substance is used and stored. DSEAR requires that the safety risks from dangerous substances are eliminated or, where this is not reasonably practicable, measures are taken to control risks and reduce the harmful effects of any fire, explosion or similar event, so far as is reasonably practicable. The Regulations identify a hierarchy of types of protection that must be considered and applied in order of priority, namely: 5.1 Substitution This involves replacing a dangerous substance with a substance or process that totally eliminates the risk. In practice this may be difficult to achieve and it is more likely that it will be more practicable to replace the dangerous substance with one that is less hazardous (e.g. by replacing a low-flashpoint solvent with a higher-flashpoint one). An alternative is to design the process so that it is less dangerous. This might include, for example, changing the manner or sequence in which the dangerous substance is added. However, care must be taken when carrying out these steps to ensure that no other safety or health risks are created or increased, which then outweigh the improvements implemented as a result of DSEAR. In reality, where the dangerous substance is handled or stored for use as a fuel, there is often no scope for elimination and very little chance to reduce the quantities handled. Where risk cannot be entirely eliminated control and mitigation measures to reduce risk must be applied in the following order of priority: 5.2 Control measures Reduce the quantity of dangerous substances to a minimum. Only the minimum amount of a flammable liquid needed to carry out a work activity should be kept in the open workroom/laboratory for example; Avoid or minimise releases. Flammable liquids present within School buildings shall, when not in use, be stored in suitable closed containers, placed in fire resistant storage designed to contain spills; Issued: 20th July 2006 Page 3 of 6 Rev 1.0 School of Life Sciences 5.3 LOCAL RULES FOR THE CONTROL OF DANGEROUS SUBSTANCES AND EXPLOSIVE ATMOSPHERES R3 Control releases at source; Prevent the formation of an explosive atmosphere; Collect, contain and remove any releases to a safe place (e.g. by ventilation); Avoid ignition sources; Avoid adverse conditions (e.g. exceeding the limits of temperature or other control settings) that could lead to danger; Keep incompatible substances apart. Mitigation measures prevent fires and explosions from spreading to other plant and equipment or to other parts of the workplace; reduce the numbers of employees exposed to a minimum; provide plant/equipment that can safely contain/suppress an explosion, or vent to a safe place. Any measures taken to achieve the elimination or the reduction of risk should take into account the design, construction and maintenance of the workplace and work processes, including all relevant plant, equipment, control and protection systems. 5.4 Explosive Atmospheres In locations where explosive atmospheres may occur, the following action must be taken: areas where hazardous explosive atmospheres may occur shall be classified into zones based on their likelihood and persistence, in accordance with DSEAR. A hazardous zone is a place where an explosive atmosphere is: Present continuously, for long periods, or frequently – Zone 0; Likely to occur occasionally in normal operation – Zone 1 Unlikely to occur in normal operation, and if so only for a short period – Zone 2 areas classified into zones shall be protected from sources of ignition by selecting equipment and protective systems meeting the requirements of the Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations (equipment already in use before July 2003 can continue to be used indefinitely provided the risk assessment shows it is safe to do so); where necessary, areas classified into zones shall be marked with a specified "EX" sign at their points of entry; where employees work in zoned areas they shall be provided with appropriate clothing that does not create a risk of an electrostatic discharge igniting any explosive atmosphere; Issued: 20th July 2006 Page 4 of 6 Rev 1.0 School of Life Sciences 5.5 LOCAL RULES FOR THE CONTROL OF DANGEROUS SUBSTANCES AND EXPLOSIVE ATMOSPHERES R3 Incidents The School has in place emergency procedures in the event of fire, etc which include evacuation, means of summoning the emergency services... However as part of the risk assessment process, consideration should be given to the need to supplement existing procedures if an incident should arise, for example an explosion or significant spillage. This could include: Suitable warning (including visual and audible alarms) and communication systems; Escape facilities; Supplementary emergency procedures; Equipment and clothing for essential personnel dealing with the incident; The scale and nature of the emergency arrangements should be proportionate to the level of risk. FIRE AND EXPLOSION - HOW SAFE IS YOUR WORKPLACE? 5.6 Implementation and Maintenance of Controls Heads of Department must ensure that control measures are implemented and maintained. Controls must be kept in good working order and in good repair. Regular checks should be made to ensure they continue to operate as intended. These checks may include visual checks, inspection, testing, servicing and remedial work, e.g. local exhaust ventilation must be tested at least once every 14 months or earlier where necessary and a written record kept for at least 5 years. Staff and students must co-operate and make full and proper use of prescribed control measures, reporting any defects. They must also participate in training and make full use of information and instructions provided. 5.7 Information, Instruction, Training and Supervision Staff, students, contractors and others working in or near hazardous zones should be provided with suitable information, instruction and training about the precautions and actions to be taken to safeguard themselves and others. This would include 6.0 Name of substances in use and risks they present Access to any relevant data sheet Significant findings of the risk assessment Required control measures Personal protective equipment required Emergency procedures FURTHER INFORMATION Further Information may be obtained from the School Safety Adviser, the University Safety Office, or from the following sources: HSE ACoP and Guidance for the Storage of Dangerous Substances (L135) HSE ACo P and Guidance for Control and Mitigation Measures (L136) HSE ACoP and Guidance for Safe Repair, maintenance and Cleaning (L137) Issued: 20th July 2006 Page 5 of 6 Rev 1.0 School of Life Sciences LOCAL RULES FOR THE CONTROL OF DANGEROUS SUBSTANCES AND EXPLOSIVE ATMOSPHERES R3 HSE ACoP and Guidance for DSEAR 2002 (L138) School Legislative Digest on DSEAR 2002 Issued: 20th July 2006 Page 6 of 6 Rev 1.0