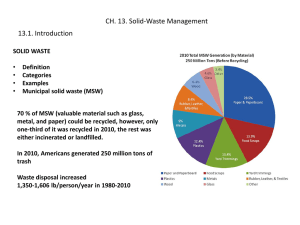

Waste Technology and Innovation Study

advertisement