BIT_22679_sm_suppInfo

advertisement

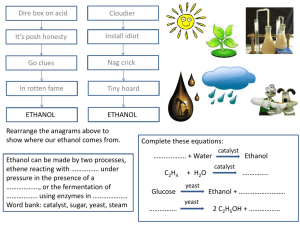

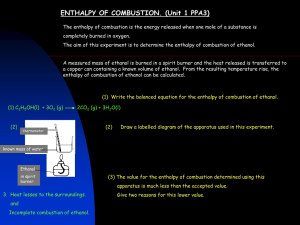

Supporting information 1. Stoichiometric Yield Comparison of MixAlco Ethanol from Acetate and Conventional Ethanol from Biomass Fig S1 compares MixAlco and conventional ethanol production from biomass. In the MixAlco process, the biomass is firstly fermented into acetate in the CBP using natural occurring acid-producing microorganisms. The resulting acetate is further hydrogenated into ethanol using hydrogen from a pipeline or refinery. In contrast, in a conventional ethanol process, the biomass is firstly hydrolyzed to fermentable sugars, which are further directly fermented into ethanol using recombinant microorganisms. a) Stoichiometric Yield for MixAlco Ethanol Fermentation C 6 H12 O 6 (glucose) 3 CH 3 COOH (Acetate) (S-1) Hydrogenation CH 3 COOH (Acetate) 2H 2 CH 3 CH 2 OH (Ethanol) H 2 O (S-2) b) Stoichiometric Yield for Conventional Ethanol Fermentation C 6 H12 O 6 (Glucose) 2 CH 3 CH 2 OH (Ethanol) 2 CO 2 1 (S-3) In the biomass-to-ethanol pathway of the MixAlco process, the substrate streams (e.g., glucose [C6]) are sent to countercurrent fermentations where the substrate is converted into acetic acid (CH3COOH) without CO2 as a by-product. In comparison, conventional ethanol fermentations produce one molecule of CO2 for every molecule of ethanol (CH3CH2OH). Therefore, the carbon efficiency of MixAlco-ethanol process is nearly 100% vs. 67% [i.e., 2C in ethanol/(2C in ethanol + 1C in CO2) = 67%] for conventional biomass-to-ethanol process. In the MixAlco process, the mixed culture of natural microorganisms produce a wide range of metabolic products (Holtzapple et al. 1999). As reported in this study, under controlled conditions (i.e., controlling pH, controlling temperature, and ammonium bicarbonate buffer), acetate content in fermentation products could reach 92% (Table 3). In contrast, pure culture deployed in a conventional biomass-to-ethanol process can produce nearly pure (100%) ethanol. The ratio of improved stoichiometric yield from conventional ethanol to MixAlco ethanol can be deducted as follows: Yield of MixAlco ethanol Yield of convention al ethnaol Yield of convention al ethanol 100% 92% 67% 100% = 37.3% 67% 100% (S-4) In summary, the stoichiometric ethanol yield in the MixAlco process is ~40% higher than that in a conventional biomass-to-ethanol process. 2 2. the Continuum Particle Distribution Model (CPDM) Modeling and optimizing mixed-culture countercurrent fermentations is extremely difficult because they involve multiple microorganisms, feedstocks, acid products, and reaction phases. Furthermore, laboratory countercurrent fermentations are time-consuming and may take several months to achieve steady state (Aiello-Mazzarri et al. 2005; Thanakoses et al. 2003); therefore, optimizing a single biomass feedstock could take years. The CPDM overcomes these problems (Chan and Holtzapple 2003). The solid reactant in the fermentor is composed of discrete particles with differing diameters (Fig. S2a). Generally, smaller discrete particles react more quickly, whereas larger discrete particles react more slowly. To avoid difficulties of tracking individual discrete particles, CPDM uses the concept of a continuum particle, which Ross defined as a collection of particles with a VS mass of one gram when entering the fermentor (Ross 1998). By definition, each continuum particle is identical to the others at the points of entry; however, once in the fermentor, they can differ in the reaction extent (conversion x) (Fig. S2b). The CPDM method characterizes the reaction rate using model parameters obtained from batch fermentations operating at varying initial substrate concentrations (40, 70, 100, and 100+ g dry substrate/L liquid). The product acid concentrations can be converted to acetic acid equivalents (): (mol/L) = acetic (mol/L) + 1.75 × propionic (mol/L) + 2.5 × butyric (mol/L) 3 + 3.25 × valeric (mol/L) + 4.0 × caprioc (mol/L) + 4.75 × heptanoic (mol/L) (S-5) On a mass basis, the acetic acid equivalent (Aceq) can be expressed as Aceq (g/L) 60.05 (g/mol) α (mol/L) (S-6) In each batch experiment, the concentrations of acetic acid equivalents were fit to Aceq (t ) a bt 1 ct (S-7) where a, b, and c are constants, and t is the fermentation time in days. Initial values for the parameters a, b, and c were guessed. The parameters a, b, and c were obtained by the least square method. The specific reaction rate ( r̂ , the reaction rate per continuum particle) is calculated by r rˆ So d (Aceq) dt S0 b (1 ct ) 2 S0 (S-8) In a batch fermentor, the initial substrate concentration So (g VS/L liquid) is defined as the initial volatile solid mass mo per volume of liquid V (So = mo/V). In a four-stage countercurrent fermentation, mo is the mass of fresh volatile solids added to Fermentor 1, and V is defined as the fresh liquid volume added to Fermentor 4 (Fig. 2b). For each batch fermentor, the biomass conversion x is calculated by x(t ) Aceq(t ) Aceq(t 0) Soσ (S-9) 4 where σ is the selectivity (g Aceq produced/g VS digested). In the CPDM method, the selectivity σ is assumed constant and calculated from the selectivity s (g total acid produced/g VS digested) by s (S-10) The average value of selectivity s is determined from the countercurrent experiments. The parameter (the ratio of total grams of carboxylic acids to total grams of Aceq) was introduced to avoid the inhibitory effects of higher acids that would overestimate the specific rate (Ross 1998). Eq. S-11 is empirical and is the governing equation in the CPDM method. It relates the specific reaction rate rˆ( x, Aceq ) with acetic acid equivalent concentration (Aceq) and fraction conversion of volatile solids (x). rˆpred e(1 x) f 1 g ( Aceq) h (S-11) where e, f, g, and h are empirical constants. The (1 – x) term was described as the conversion penalty function (South and Lynd 1994). The least square method was used to determine the empirical constants e, f, g, and h. The resulting Aceq was converted back to total carboxylic acid concentration using parameter . 5 References Aiello-Mazzarri C, Coward-Kelly G, Agbogbo FK, Holtzapple MT. 2005. Conversion of municipal solid waste into carboxylic acids by anaerobic countercurrent fermentation Effect of using intermediate lime treatment. Applied Biochemistry and Biotechnology 127(2):79-93. Chan WN, Holtzapple MT. 2003. Conversion of municipal solid wastes to carboxylic acids by thermophilic fermentation. Applied Biochemistry and Biotechnology 111(2):93-112. Holtzapple MT, Davison RR, Ross MK, Aldrett-Lee S, Nagwani M, Lee CM, Lee C, Adelson S, Kaar W, Gaskin D and others. 1999. Biomass conversion to mixed alcohol fuels using the MixAlco process. Applied Biochemistry and Biotechnology 77-9:609-631. Ross MK. 1998. Production of Acetic Acid from Waste Biomass [Ph.D. dissertation]. College station, TX: Texas A&M University. South CR, Lynd LR. 1994. Analysis of Conversion of Particulate Biomass to Ethanol in Continuous Solids Retaining and Cascade Bioreactors. Applied Biochemistry and Biotechnology 45-6:467-481. Thanakoses P, Black AS, Holtzapple MT. 2003. Fermentation of corn stover to carboxylic acids. Biotechnology and Bioengineering 83(2):191-200. 6 Figures Caption Fig. S1. Routes to converting biomass to ethanol. Fig. S2. Overview of continuum particle in the CPDM method. a) Definition of continuum particle; b) reactant conversion from a continuum particle. Fig. S3. Routes to fuels and chemicals in downstream processing starting from carboxylate salts. End products of the MixAlco process are mixed primary alcohols (e.g., ethanol), mixed secondary alcohols (e.g., isopropanol), and hydrocarbons (e.g., alkanes). The intermediate products (e.g., acetic acid) are valuable chemicals and could be sold as desired products. Fig. S4. Pretreatment devices used to treat sugarcane bagasse with aqueous ammonia. a) Modified temperature-adjustable oven; b) Self-constructed high-pressure reactors; c) Roller system; d) 1-L centrifuge bottle. Both a) and b) are for short-time ammonia treatment, whereas c) and d) are for long-term ammonia treatment. 7 Sugars Conventional ethanol Pure-culture fermentation Substrate hydrolysis Biomass Ethanol Acetate MixAlco ethanol Mixed-culture fermentation Hydrogeneration Fig. S1. 8 Fig. S2. 9 Carboxylate salt Ac id sp rin gin g Carboxylic acid Ketone Ester H2 H2 Secondary alcohol Ol (ze igom oli eri te cat zatio aly n st) n tio ) iza st er ly m ata igo te c Ol eoli (z Oligomerization (zeolite catalyst) Ether Hydrocarbons Fig. S3. 10 Primary alcohol Fig. S4. 11