Paper

advertisement

MOLECULAR DYNAMICS SIMULATION OF SOLID/SOLID

INTERFACE IN METALS.

D.Novikov, N.Lyakhov

Institute of Solid State Chemistry and Mechanochemistry,

Kutateladze, 18, Novosibirsk, 630128, Russia

ABSTRACT. Molecular dynamics simulation of interface between two solid Ni and

Al metallic phases using an embedded atom interatomic potential [1] was performed.

Structural transformations were analyzed using geometrical Delaunay approach.

Several types of structural transformations of lattice nearby interface were detected.

An attempt to analyze size effect in metallic mixture was taken. Results seem to

correlate with that obtained experimentally and are likely to explain altogether with

data obtained from Delaunay analysis some features of processes and mechanisms of

mechanical alloying.

INTRODUCTION

Delaunay geometrical approach [2] to the simulation data analysis appears to be

the novel and promising method for structural studies. It can be used to study different

types of structure defects and nonideal sites. Interfacial boundary seems to be very

beneficial object for Delaunay analysis to apply.

During mechanochemical synthesis of intermetallic compounds in the ball mill

AGO2, often at the initial stages layered mechanocomposites are formed. In these

mechanocomposites obtained by short time mechanical activation interfacial

boundaries constitute sufficient part of substance and affect its properties. There are

many questions about formation of mechanocomposites and their evolution during

synthesis. A phenomenon of formation of nanosized metal particles mix in many

bimetallic systems including Ni/Al [3] at the initials stages of mechanical alloying is

very intriguing.

3 - 88

THEORY

Some features of Delaunay approach to the interfacial interatomic configuration

analysis are listed below.

For the structure analysis methods based on Delaunay triangulation were used.

Lately this method is widely used for studying dense solids and liquids. In the present

work the system under investigation was divided into quadruples of points – the

simplexes of Delaunay, arranged in such a manner that no point of system is inside

the circumsphere of any simplex, and simplexes fulfill whole space of the system

without superpositions and interstices. In the perfect BCC lattice such simplexes are

perfect tetrahedron and quadrahedron (a quarter of perfect octahedron). Measure to

evaluate the similarity of simplex shape to perfect tetrahedron can be introduced in the

following way [4]:

T=

(li - lj)2/(15 <l>2), where i<j.

Or perfect quadrahedron:

O=

(li - lj)2/(10 <l>2) +

(li – lm/1.1415)2/(5 <l>2), where i<j; i, j

m;

Where li – lateral length of Delaunay simplex, lm – longest lateral length of

quadrahedron simplex, <l>=(1/4)*

(li), where i = 1 to 4. The less magnitude of that

measures the closer shape of the simplex to perfect one.

It is useful to declare measure S, characterizing the perfectness of simplexes:

S = min (T, O).

This measure is used in present work for structure analysis.

A center of simplex is equal to the center of its circumsphere.

In the current research several free programs were used: Qhull [5] for

computation of Delaunay triangulation, and Rasmol [6] for visualization.

RESULTS AND DISCUSSION

Several systems were modeled and analyzed.

In the first model an intermixing of Ni and Al atoms was observed using a

special function taking in account atom type of geometrical members of Delaunay

triangulation. A number of Ni atoms to have minimal number of Ni neighbors and

3 - 89

maximum number were computed. A system for analysis was constructed in a very

simple manner. A cube in periodical boundary conditions of aluminum lattice (FCC,

{100}, a = 0.4049 nm) with an edge of x was created, and then a smaller cube with an

edge of x/2 was extracted from it and filled with Ni atoms (FCC, {110}, a = 0.3524

nm). Afterwards the system was quenched, relaxed and heated.

For a number of systems with x = 1.6; 2.4; 2.8; 3.2 nm computations were made.

A smallest one with an edge of 1.6 nm was exposed at several temperatures. In the

temperature range of 630-690K fast intermixing of metal atoms was detected. The

temperature 630K was chosen as basic one, as it is sufficiently lower than the melting

temperature of Ni and Al phases, and it is reachable in the course of mechanochemical

synthesis.

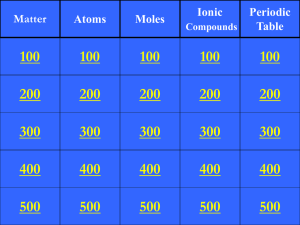

All four systems were exposed at the temperature of 630 K for a period of about

one nanosecond. A function characterizing a depth of intermixing was constructed

with the use of Delaunay graph. Number of atoms to have many Ni neighbors (almost

pure Ni) and a few (mostly Al) was calculated. See Fig. 1.

1,0

Function of distribution of Ni neighboring atoms

at 630 K for systems of diffrernt sizes

Y, Relative friqency of appearence

0,9

0,8

0,7

number of atoms to have

many Ni neighbors

number of atoms to have

a few Ni neighbors

0,6

0,5

0,4

0,3

0,2

0,1

0,0

1,6

2,0

2,4

2,8

3,2

X, size (nm)

Fig. 1. Shows a depth of intermixing of components in the Ni/Al model system.

At the temperature of 630 K and system size of 2.8, 3.2 nm little or no intermixing

occurs.

3 - 90

The second system was constructed of two layers ~ 16x6x4 nm each. The upper

layer consists of Ni atoms (FCC, {110}, a = 0.3524 nm) and the lower one of Al

atoms (FCC, {100}, a = 0.4049 nm). Simulation was carried out in periodic boundary

conditions at constant temperature. The system was quenched and relaxed.

Geometrical Delaunay analysis of reconstruction of lattice nearby the interface was

performed. On the Fig.2 and Fig.3 tiny lines connect centers of imperfect (S>1.1)

simplexes that are closer than 0.2 nm. Imperfect simplexes are generally allocated in

the part of the system referring to Al. As we can see at Fig.2 nearby interface

boundary there appears to be a superstructure allocated in Al with a period of about

1.8 nm, getting ~ 1.3 - 1.5 nm deep in Al site. This superstructure is formed of high

concentration of imperfect simplexes. Their occurrence states a severe lattice

deformation, especially at the borders of “cells”. Moreover in the centers of that

“cells” lattice appears to be almost perfect, unchanged. All the statements above

should be referenced to Al only as Ni site is particularly unchanged (see Fig.3, Fig. 4).

Deformation of Ni is only one or two atoms deep. It is worth mentioning a formation

of a specific “monolayer” of Al next to Ni interface. Its structure along the interface

has common RDF function (if calculated in 2D plain parallel to Ni interface) to

intermetallide Ni3Al. This monolayered structure might serve as a barrier for diffusion

and intermixing of metal atoms.

Fig. 2 Shows cellular structure nearby the interfacial boundary between Ni and

Al, the view from above, regarding to the interfacial plain.

3 - 91

Fig. 3 Shows structure nearby the interfacial boundary between Ni and Al, side

view, regarding to the interfacial plain. Imperfect simplexes are mostly allocated in

the Al part.

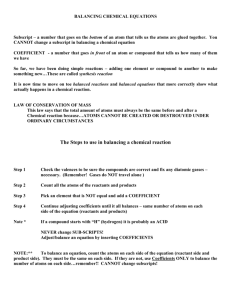

12

Y, N/<N(Al)>

10

Al

Ni

8

6

4

2

0

-3

-2

-1

0

1

2

X, nm

Fig.4 On the diagram a number of imperfect simplexes is shown as a function of

distance from the interfacial border. Negative semi-axis refers to Al, positive to Ni.

Number of simplexes is normalized by the average number of imperfect simplexes in

Al.

3 - 92

The third model to mention was an attempt to simulate intensive plastic

deformation of double layered solid system. The model was almost the same as model

two. Though it was simulated not in static conditions but within a dynamic stress

applied to the central part of model cell perpendicular to the interfacial border. In

periodical boundary conditions such stress application has lead to formation of tiny

layers of components, slightly variable in thickness. Afterwards the system was

relaxed for several nanoseconds at 400K. After relaxation the thinnest parts of layered

system were sufficiently intermixed and thicker ones were almost unchanged.

Characteristic thickness of layer to mix was 1.5-1.8 nm and to stay stable 2.5-3.0 nm.

SUMMARY

At the temperature of about 630 K and component thickness of 1.5-2.0 nm there

appears to be fast intermixing common to Spontaneous Alloying [7,8]. It takes place

within the bulk mixture of small sized components.

For the large double layered system two structures can be stated to form nearby

interface: a “cellular” system with a period of 1.8 nm, and Ni3Al like structure that

might serve as a barrier for diffusion and intermixing of atoms.

The critical size that can be estimated from the first cube model can be

explained using results obtained from the second one. As the characteristic

superstructure “cell” length is about 1.8 nm – for the components with a less size it

cannot be formed and lattice cannot relax. That might lead to manifestation of size

effect in the metal particles mix.

REFERENCES

1 A.F. Voter and S.P. Chen ‘Accurate Interatomic Potentials for Ni, Al, and

Ni3Al’ Mat. Res. Soc. Symp. Proc., 175 (1987).

2 Delaunay B.N. ‘Sur la sphere vide’ Proc. of Int. Math. Congress in Toronto,

Aug. 11-16, 1924. Toronto: Univ. of Toronto press. 1928 (Cited by [4]).

3 Yelsukov E.P., Dorofeev G.A., Barinov V.A., Grigorieva T.F., Boldyrev

V.V. ‘Solid state reactions in the Fe-Sn system under mechanical alloying.’ Mater.

Sci. Forum 1998 v. 269-272 (1) 151-156.

3 - 93

4 Medvedev N.N.: Voronoy-Delaunay approach to investigation of structure

of noncrystalline systems. Novosibirsk SBRAS 2000.

5 Barber, C.B., Dobkin, D.P., and Huhdanpaa, H.T. ‘The quickhull algorithm

for

convex

hulls’

ACM

Trans.

on

Mathematical

Software,

Dec

1996.

http://www.geom.umn.edu/software/qhull

6 RasMol V2.7.2.1 (Biomolecular Structures Group, Glaxo Wellcome

Research & Development).

7 Yasuda H., Mori H. ‘Phase equilibrium in nanometer-sized Sb-Au alloy

clusters.’ Mater. Sci. Forum 1998 v. 269-272 p. 333-338.

8 Mori H., Yasuda H. ‘Spontaneous alloying in nanometer-sized ultra fine

particles.’ Mater. Sci. Forum 1998 v. 269-272 p. 327-332.

3 - 94