Appendix for the paper Direct measurements of

advertisement

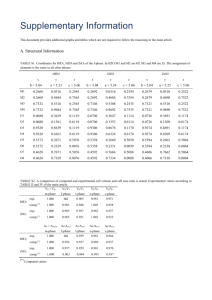

Appendix for the paper Hafnia: energetics of thin films and nanoparticles by Wei Zhou, Sergey V. Ushakov, Tuo Wang, John G. Ekerdt, Alex A. Demkov, and Alexandra Navrotsky, submitted for publication in Journal of Applied Physics to be deposited with Electronic Physics Auxiliary Publication Service (EPAPS) TABLE OF CONTENTS FIG. 1. Experimental setup used for time-resolved high-temperature measurements on NSLS beamline X7b. FIG. 2. X-ray diffraction patterns of 76 nm HfO2 films at different temperatures on Inel CPS120 diffractometer FIG. 3. Thermal analysis of amorphous HfO2 powder served as a precursor for synthesis of monoclinic hafnia. FIG. 4. Temperature program and 2D plot of XRD patterns on heating of amorphous HfO2 powder with corundum standard. FIG. 5. 3D plot of illustrating crystallization of amorphous HfO2 directly into monoclinic phase at 450 °C. FIG. 6. Bright field TEM micrographs of monoclinic HfO2 samples used for solution calorimetry. FIG. 7. Particle size distributions in monoclinic HfO2 samples used for solution calorimetry. FIG. 8. Total water content from TG versus BET surface area for monoclinic HfO2 samples used for solution calorimetry. FIG. 9. Enthalpy of drop solution (corrected for physisorbed and chemisorbed water and for surface energy contribution assuming 2.78 J/m2 reference value) plotted versus interface area. The negative of the slope yields interfacial energy 1.6 ±0.1 J/m2. FIG. 1. Experimental setup used on NSLS beamline X7b with Mar345 image plate. Red lines show Xray beam path and diffraction cones. Sapphire tube (Saphicon, 1mm OD, 0.7 mm ID) was filled with amorphous HfO2 powder mixed with -Al2O3 and inserted into a spiral of Kanthal wire. K type thermocouples (0.01" Omega HKMQSS-010U-6) were inserted inside the tube to contact the sample and were used control the furnace and to record the sample temperature using Omega controller. The single crystal reflections from sapphire tube were cut out from two dimensional diffraction patterns with FIT2D software and the powder rings were integrated. Wavelength (0.92203 Å) and sample to detector distance (192.085 mm) were calibrated with LaB6. Refinement of cell parameter of Si 640b NIST standard material gave the value 5.4308(1) (wRp 6.6%), what is within uncertainty from standard value 5.430940(35). o 500 C o 450 C o re 400 C atu o pe r 350 C o Tem 300 C o 200 C 10 15 20 25 30 2 (degree) 35 40 45 FIG. 2. X-ray diffraction patterns of 76 nm HfO2 films at temperatures labeled. Measurements were performed in air using high temperature attachment of Inel CPS120 diffractometer, Co Kα radiation (λ = 1.7902 Å), heating rate of 10 oC/min and collection time of 60 minutes per pattern. Crystallization into monoclinic phase is apparent at 400 °C from two peaks at 40-45° (2 θ). 4.5 100 96 92 1.5 TG (%) DSC (mw/mg) 3.0 88 0.0 84 200 400 600 800 1000 1200 o Temperature ( C) FIG. 3. Thermogravimetry (TG) and differential scanning calorimetry (DSC) traces on heating in oxygen at 20 °C/min of amorphous HfO2 powder served as a precursor for synthesis of monoclinic hafnia nanoparticles. Weight loss of ~15 wt% observed from 25-650 °C. Endothermic peak on DSC trace below 400 °C corresponds to water loss, exothermic peak at 545 ± 7 °C corresponds to HfO2 crystallization in monoclinic phase with crystallization enthalpy -24 ± 7 kJ/mol (average from three experiments). 3000 - (111) (111) 120 4000 Time, min 100 80 60 40 20 100 300 500 T, °C FIG. 4. Time-resolved high temperature X-ray diffraction patterns on amorphous HfO2 powder with corundum internal standard (NSLS beamline X7b wavelength 0.92203 Å) Collection time was 100 seconds per pattern with ~80 seconds image plate read-out time. Sample temperature is shown on the left panel. Red overlaid trace is the fit of the last pattern with strongest lines for monoclinic HfO2 indexed. Amorphous HfO2 crystallizes directly into monoclinic phase after 40 minutes at 450 °C. BET surface area of amorphous HfO2 measured before crystallization in a separate experiment was 85 m2/g. 4k 3k 2k 10 20 30 2-Theta Angle (Degrees) FIG. 5. Crystallization of amorphous HfO2 into monoclinic phase at 450 °C (with corundum as internal standard). 3D plot of the 10-30° 2-Theta region ( = 0.92203 Å) of XRD patterns collected with 180 s interval. Intensity is plotted on the Y-axis in logarithmic scale. Direct crystallization into monoclinic phase is apparent from appearance of strongest (-111) and (111) m-HfO2 peaks in 15-20 ° 2-Theta region. See figures 2 and 3 on details on experimental setup and temperature program. FIG. 6. Bright field TEM micrographs of monoclinic HfO2 samples used for solution calorimetry. Annealing temperature (oC) indicated in the upper left corner. Measured with Phillips CM12 transmission electron microscope at 120 kV with LaB6 filament. Magnification of electron microscope was calibrated with Ted Pella standard #603. Counts 13±4 nm (77) 650 °C 18±5 nm (48) 700 °C 32±9 nm (70) 800 °C 36±11 nm (89) 900 °C 46±12 nm (91) 950 °C 44±13 nm (67) 1000°C 0 20 40 60 80 Particle size (nm) FIG. 7. Particle size distributions in monoclinic HfO2 samples used for solution calorimetry. Measured with Phillips CM12 transmission electron microscope operated at 120 kV with LaB6 filament. Magnification was calibrated with TedPella standard #603. Average size with standard deviation (total number of particles counted is given in parentheses) and annealing temperature are labeled in the top right corner. Water content (mol) 0.20 0.15 0.10 0.05 0.00 0 2000 4000 6000 8000 2 Surface area (m /mol) FIG. 8. Total water content from TG versus BET surface area for monoclinic HfO2 samples used for solution calorimetry. Hds-2 - 0.00278*SA (kJ/mol) 20 19 18 17 16 15 14 0 600 1200 1800 2400 2 Interface area (m /mol) FIG. 9. Enthalpy of drop solution (corrected for physisorbed and chemisorbed water and for surface energy contribution assuming 2.78 J/m2 reference† value) plotted versus interface area calculated from Eq. 1 (IA = 0.5[SA(XRD)-SA(BET)]). The negative of the slope yields interfacial energy 1.6 ±0.1 J/m2. †A. B. Mukhopadhyay, J. F. Sanz, and C. B. Musgrave, Chem. Mat. 18 (15), 3397 (2006)