CHAPTER2

advertisement

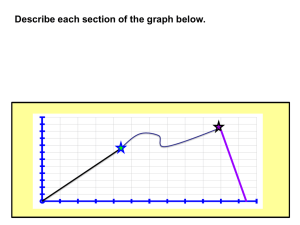

CIVL 111 CONSTRUCTION MATERIALS CHAPTER 2 - MECHANICAL BEHAVIOUR OF MATERIALS 2.1 ELASTIC BEHAVIOUR 2.1.1 Introduction Under a small load, all materials behave in an elastic manner. When stress is applied, strain will be resulted. Once the stress is removed, the material returns to its original state (i.e., the strain goes back to zero). Moreover, before a certain critical state is reached, the stress and strain are linearly dependent on one another. Linear elastic behaviour is the basic assumption of many engineering analyses. In this section, we are going to investigate the physical basis of linear elastic behavior, define the Young’s modulus and describe how it affects structural design. Then, we will study the elastic behaviour of composite materials (i.e., when two or more materials are used in combination to carry the load). This will provide a foundation for the understanding of reinforced concrete design, which will be taught in another class. 2.1.2 Physical Basis of Elastic Behaviour To most of us, the first manifestation of elastic behaviour is perhaps the behavior of a spring. On loading, the deformation is clearly visible and on unloading, the spring returns to its original length. The elastic behaviour of all materials can be explained in terms of the simple spring. As we all know, materials consist of atoms that are held in equilibrium positions by bonds. Since the bond force is linearly dependent on interatomic distance, bonds can be considered as small springs placed between atoms (Fig.2.1). When loading is applied, the atoms will move relative to one another. The movement will stop once the bond force (resulting from change in interatomic distance) is in balance with the applied force. Once the loading is removed, the atoms will move back to the original equilibrium positions. The behaviour of the whole material is therefore linear elastic. In Fig.2.1, for simplicity, we have only considered the presence of bonds along the direction of the loading. In reality, there are interactions between neighbouring atoms at all directions. (Actually, the interaction may extend beyond the first layer of neighbours, but this is beyond the scope of our discussion here). Fig.2.2 shows an example of such kind of interaction. Again, if we consider the bond to be a spring, when loading is applied in the direction shown in Fig.2.2, the stretching of the spring results in forces with two components, one parallel to the applied load and the other perpendicular to it. As a result, under loading, 5 materials not only deform parallel to the loading direction, but will also deform perpendicular to it. This deformation is called the Poisson’s effect and is important in understanding the effect of confinement on material behaviour, a topic of importance in reinforced concrete column design. Bond behaves like spring Displacement of atom as bond stretch under load Figure 2.1 Displacement of atoms under applied loading Vertical component of spring force pulls atoms away from one another Horizontal component of spring force moves atoms closer to one another Figure 2.2 Illustration of the Poisson’s Effect 6 2.1.3 Young’s Modulus: Definition, Typical Values and Significance to Structural Design In the linear elastic regime, the stress () and strain () are directly proportional to one another. The Young’s modulus, E, is defined as: E = / The Poisson’s ratio is defined as: = - (strain perpendicular to loading direction) / (strain along loading direction) Note the negative sign in the equation for : with this definition, the situation illustrated in Fig.2.2 will result in a positive value of . As examples, = 0.28 for steel and range from 0.14 to 0.20 for concrete. In some applications, which involve the shear deformation of materials, the shear modulus G is used. For an isotropic material, which is defined as a material with equal properties in all directions, G is related to E and through: G = E / 2(1+) A high value of E means that a high level of stress is required to produce a given strain. The material is then said to have a high stiffness. Physically, the magnitude of E is governed by the intensity of the bond between atoms. Primary bonds such as covalent, ionic and metallic bonds result in high E values. Secondary bonds, including hydrogen bond and van der Waal’s force, give rise to low values of E. The Young’s moduli for common materials are given in Table 2.1. The covalent bonded diamond is the stiffest material in the world and included here as a reference. Steel, which is held by metallic bonds, has a high modulus of around 200 GPa. Wood and polymers have a low modulus of 16 GPa or below. Both wood and polymers are built up of long chains of carbon atoms. Along the chain, the atoms are covalent bonded and therefore the stiffness is very high. However, individual chains are held together by either the weak secondary bonds or occasional cross-links. It is therefore quite easy for the chains to slide relative to one another, resulting in the low E values. The modulus of concrete, depending on mix proportions, is around 20 to 40 GPa. Concrete consists of many different chemical phases, fine and coarse aggregates as well as pores. Its modulus is affected by many factors and we postpone the discussion to the chapter on concrete. It is important for us not to confuse between the two concepts of strength and stiffness. For example, aluminum and glass both have a modulus of 69 GPa. That is, they have comparable stiffness. However, their strength and failure modes are completely different. 7 Table 2.1 Reference E values (in GPa) for common materials Diamond 1,000 Wood ( // grain ) 9 - 16 Steel 190 - 210 Wood ( | grain) 0.6-1 Aluminum 69 Polyesters 1-5 Glass 69 Epoxies 3 Concrete 20 - 40 Ice (H2O) 9.1 The Young’s modulus is the material parameter governing the deformation of a structure (Note: deformation is of course also affected by the member size). When material of a lower E is used to replace one with a higher E (e.g. aluminum is employed to replace steel to reduce environmental corrosion), the deflection should be checked to make sure that it is not excessive. A reduction of E will also increase the likelihood of buckling failure, which is the sudden lateral deflection of a slender member under compression (This can be easily illustrated by compressing a thin plastic ruler). It should be noted that when a material is damaged, its E value is always reduced. Since the speed of stress wave propagation in a material is proportional to the square root of E, the wave speed in a damaged material will also be reduced. By sending a wave into a structural member and measure the time for it to travel between two points, the damage condition of a structure can be assessed in a nondestructive manner. 2.1.4 Modulus of Composite Materials: Application to Reinforced Concrete Column In this section, we will consider the elastic behavior of composite materials. This is of relevance because: (i) the same concepts apply to the analysis of reinforced concrete members, (ii) there is increasing interest in the use of fiber reinforced composites in civil engineering applications. Our discussions will be limited to composites with two phases, but they can be easily extended to more general cases. Only two simple cases will be considered. In both cases, the two phases are considered to be planar and aligned in the same direction (Fig.2.3). In case 1, the loading is applied parallel to the aligned direction, and in case 2, the loading is applied perpendicularly. The analysis of each case is given below. Case 1: Loading along aligned direction Assume a total load carrying area of A, and an average applied stress of . The total applied force is therefore given by A. Let Va be the volume fraction of phase A, and Vb (= 1 - Va) be the volume fraction of phase B. Phases A and B are bonded together. When loaded in parallel, they must deform by the same amount (otherwise, they will not be fitted together 8 any more). In other words, the strain in each phase (along the loading direction) must be the same, i.e., a = b = . The stress in the phases are then given by: a = Eaa= Ea b = Ebb = Eb The force carried by each phase is equal to the stress in each phase multiplied by the area: Fa = VaAa = VaA Ea Fb = VbAb = VbA Eb Force equilibrium requires F = Fa + Fb, which gives: = (VaA Ea + VbA Eb) or, E = = (VaEa + VbEb) This is called the parallel model, which states that the composite modulus is simply the weighted average of the phase moduli, with the corresponding volume fraction used as the weight. H CASE 1 Loading along aligned direction CASE 2 Loading perpendicular to aligned direction Figure 2.3 Calculation of composite modulus for two different cases Case 2: Loading perpendicular to the aligned direction In this case, since the two phases are loaded in series, the stress on each phase must be the same in order for equilibrium to be satisfied. That is, a = b = , where is the applied stress. The strain in each of the two phases are: a = / Ea b = / Eb Assuming the thickness of composite to be H. The total extension in phases A and B are given by: 9 ea = a Va H eb = b Vb H For the composite, the total extension is given by e = H. Since e = ea + b, = ( Va/Ea + Vb/Eb ) or E = = ( Va/Ea + Vb/Eb )-1 It should be noted that cases 1 and 2 give the upper and lower bound for the elastic modulus of a composite system. In a composite with any arbitrary arrangement of the two phases, the modulus will always lie between the values given by the two expressions derived above. Example: Elastic Behavior of a Reinforced Concrete Column A 200 mm x 400 mm rectangular concrete column is reinforced with six 25 mm diameter bars. The length of the column is 3 m. An axial load of 1000 kN is applied. How much would the column be shortened and what are the stresses in the concrete and the steel? (Take Es =200 GPa, Ec = 26.7 GPa) Solution: The volume fraction of steel is given by: 6(12.5)2/(200x400) = 0.0368 Since steel and concrete are loaded in parallel, the effective modulus is given by: E = (0.0368) (200) + (1-0.0368) (26.7) = 33.08 GPa Shortening of the column = [1000 x 103 (N) / (200 x 400 (mm2)x 33.08 x 103 (N/mm2) )] x 3000 (mm) = 3.78 x 10-4 x 3000 (mm) = 1.134 mm Stress in steel = 3.78 x 10-4 x 200 x 103 (N/mm2) = 75.6 N/mm2 (or 75.6 MPa) Stress in concrete = 3.78 x 10-4 x 26.7 x 103 = 10.1 MPa NOTE: When reinforced concrete members are subjected to bending, the strain varies over the depth of the member. To analyze its behavior, we make a similar assumption: the strain in the steel is equal to that in the adjacent concrete. Details will be left to the class on reinforced concrete design. 10 2.2 PLASTIC BEHAVIOUR 2.2.1 Phenomenon of Plastic Yielding When loading on a piece of metal is continuously increased, yielding will eventually occur. Plastic yielding is indicated by a significant increase in deformation with a relatively small increase in load (or, in the case of mild steel, with no increase in load). The ultimate load carrying capacity, however, is higher than the load at which yielding first occurs. As a result, the large deformation after yielding serves as warning before final failure occurs. Materials that yield are often referred to as ductile materials, and ductility is a desirable feature for all structures. The stress-strain behaviour of a typical metal is shown in Fig.2.4 below. From the figure, the following can be defined: y : yield strength, the point where a sudden change in slope occurs 0.1% : the 0.1% proof stress, obtained from a line starting from 0.1% and extending parallel to the initial slope. This is often used when an abrupt change in slope is difficult to identify. One can also report the proof stress at other strain levels (0.2%, 0.3%) based on the same concept. TS: ultimate strength of the material f : tensile ductility or the plastic strain after failure TS Hardening Onset of Necking Tensile Fracture y Unloading line following initial slope f Figure 2.4 Stress-Strain Curve for most Metals 11 For most metals, once the yield strength is reached, continuous straining will be accompanied by a more gradual increase in stress. This stress increase is referred to as hardening. During the hardening state, the deformation is still uniform along the member (i.e., the strain is the same at all points). Once the ultimate strength is reached, localization of deformation starts to occur at a particular section. On further straining, the area of this section becomes smaller and smaller. This phenomenon is called ‘necking’ as strain localization leads to the formation of a ‘neck’ along the loaded member (see illustration in Fig.2.4). Final failure is due to plastic fracture, and the member breaks into two parts. When the two parts are fitted back together, the length (L) is often significantly above the original length (Lo). The ratio (L - Lo)/Lo is called the tensile ductility. For steel, this value can range from 0.1 to 0.6, depending on the grade. The stress strain curve shown in Fig.2.4 is applicable to most metals. However, it does not represent the behaviour of mild steel, a material widely used in construction. The stress strain curve of mild steel is shown in Fig.2.5. The curve exhibits an upper yield point and a lower yield point. With further straining beyond the lower yield point, a constant stress region (called the yield plateau) is observed before the material starts to harden like other metals. It should be noted that the upper yield point depends on loading speed and specimen type, while the lower yield point stays constant. As a result, the lower yield stress is taken to be the yield strength of mild steel and is the value used in structural design. Upper and Lower Yield Points Hardening Unloading line following initial slope Figure 2.5 Stress Strain Curve for Mild Steel 12 2.2.2 Physical Basis of Plastic Behaviour The physical origin of plasticity has remained a puzzle for many years. Considering the simple spring model in Fig.2.1, plastic behaviour will be resulted if each spring behaves in a plastic manner. In other words, the bond force has to vary with distance in a way similar to the stress strain curve. Analysis of inter-atomic interactions based on electrostatic theory indicates that this is not the case. Moreover, analysis shows that the stress required to break the bond is about one order of magnitude lower than the Young’s modulus. For most metals, however, the yield strength (and tensile strength) is about two to three orders of magnitude lower. How can this be explained? The answer to this interesting question also provides a basis for explaining plastic behaviour. A key in understanding plastic behaviour is the observation that atomic bonds do not all break at the same time. Since only a small fraction of bonds are broken at a given time, the applied stress at which bond breakage occurs is a lot lower than the theoretical value. When forces are applied along bonds to pull them apart (as in Fig.2.1), there is no mechanism for bonds to break one by one. However, if shear stress is applied, bonds can easily break and re- A C B D A B A D A B C B C D E F G H B C D E F A C E D F H b G Fig.2.6 Illustration of Plastic Deformation due to Dislocation Movement 13 form one after another. This process is difficult to explain in words but is illustrated in Fig.2.6. One can observe from the figure that shearing leads to the stretching of bonds between two horizontal layers (between atoms A and B, C and D). Eventually, these bonds will be broken and replaced by a new bond between atoms A and D. The breaking and reformation of bonds (between different pair of atoms) result in an extra plane of atoms in the atomic lattice. Such an extra plane is called a ‘dislocation’. On further shearing, additional bond breaking and re-formation move the dislocation from one side to the other side of the atomic block. A ‘step’ equal to the atomic spacing is then created. Continuous application of the shear stress can result in another series of bond breaking and re-formation, leading to additional displacement between the upper and lower blocks. The relative sliding between the two blocks is the cause of the large strain after yielding. In Fig.2.6, for illustration, we show the formation of a dislocation under applied stress. In real materials, dislocations pre-exist everywhere inside the atomic lattice. When shear stress of a sufficient magnitude is applied, dislocation movements occur all over the material. The material can then be considered as consisting of many separate ‘blocks’ trying to slide relative to one another. The strain in the material is therefore made up of two parts: the elastic stretch of bonds within each block, and the relative sliding between the blocks. The elastic part of the strain is completely recoverable on unloading, while the sliding leads to the irrecoverable plastic strain. This is the reason the unloading line after yielding is parallel to the loading line. Since dislocations can move in different directions, the blocks also tend to slide in different directions and can eventually get into the way of one another, making movement more difficult. This explains the existence of the hardening regime, where increased stress is required to continue the yielding process. The dislocation theory described above implies that yielding is resulted from shear stresses. When there is no shear stress (e.g., equal tension is applied in all directions), yielding will not occur. As a result, a criterion for yielding should be based on the shear stress. A discussion of common yield criterion will be postponed to the chapter on steel. To increase the yield strength (or, to ‘harden’ the material), the resistance to dislocation movement has to be improved. Since many hardening techniques can lead to a reduction in ductility of the material, the potential compromise between strength and ductility of metals should be kept in mind. Specific hardening methods for steel and their effect on ductility will also be presented in a later chapter. 14 2.2.3 Modelling of Plastic Behaviour Fig.2.7 shows two models for plastic behaviour. In structural analysis, the elastic/perfectly plastic model is often used for two reasons. First, it is a good approximation for mild steel, which is commonly used in construction. Second, for a hardening material, it simplifies the analysis and provides conservative results. The rigid perfectly plastic model is employed for the calculation of ultimate collapse load for a ductile structure. Since collapse occurs at a strain much higher than the yield strain, the initial elastic part can be neglected in such an analysis. Rigid/Perfectly Plastic Model Elastic/Perfectly Plastic Model Figure 2.7 Models for Plastic Behaviour 2.2.4 Illustration of Plastic Behaviour with a Parallel System To illustrate plastic behaviour of structures, we will consider the parallel system shown in Fig.2.8 below. The simple system consists of several members working together to carry the applied load. One of the members will yield before the others. Real structures consists of many members to carry the load (e.g., a building with many columns plus an internal core to carry wind load, a bridge with multiple spans, each contributing to carrying the traffic load on other spans). Each individual member will generally yield at a different load. The qualitative behaviour of the simple system in Fig.2.8 therefore resembles that of a real structure. By studying the simple system, post-yielding behaviour of real structures can be understood. 15 3 1 2 y 2L L Rigid Bar y u : applied displacement Figure 2.8 A Parallel System to Illustrate Plastic Behaviour In Fig.2.8, let’s assume all members to have the same cross sectional area A. The objective is to find the load (F) corresponding to a given displacement (u). The members do not yield at the same displacement. For members 1 and 3, yielding occurs when: u = 2Ly For member 2, yielding occurs when: u = Ly Elastic Stage: 0 < u/L < y F = AEu/L + 2AEu/(2L) = 2(AE/L)u The first term is the contribution from member 2 and the second term is from 1 and 3. Bar 2’s yielding Bar 2’s yielding occurs when: u = uy = Ly Fy = 2AEy After First Yielding: y < u/L < 2y F = AEy + 2AEu/(2L) = AEy + 2AEy/2 + 2AE(u-Ly)/(2L) = Fy + (AE/L) (u - uy) Before bar 2’s yielding, the load increment is proportional to 2AE/L. After yielding, the increment is proportional to AE/L (Fig.2.9). With bar 2’s yielding, the structure becomes more flexible on further loading. This is a general feature observed in any structure with plastic members. 16 F u - uy AE/L Fy 2AE/L uy u Fig.2.9 Load vs Displacement for a Parallel system with Elastic/Perfectly Plastic Members Whole system’s yielding When the deformation of the whole system reaches 2 Ly , bar1 and 3 will yield. Thus the whole system is yielded. The ultimate load capacity of the system is reached when the whole system yields. The ultimate load is given by 3AEy. Let’s compare this with the ultimate load of a brittle member system. The strength and failure strain of the brittle material are taken to be y and y. Since the material is brittle, once y is exceeded, the stress will drop to zero immediately. At = y, failure occurs in member 2. The load at this moment is F = 2AEy. After failure, member 2 cannot carry any load. The remaining load carrying capacity of members 1 and 3 is also 2AEy. In other words, once the middle member fails, the system cannot carry additional load and the whole system collapses. This illustrates another advantage of ductile materials over brittle materials. Even if the materials possess the same strength (y in this case), the ultimate load carrying capacity of the ductile system can be significantly higher than that of the brittle system. 17 2.3 TIME DEPENDENT BEHAVIOUR - CREEP 2.3.1 Phenomenon of Time Dependent Behaviour For many materials (e.g. polymers, wood, concrete), the response to stress or strain has a time dependent component. For example, when a fixed stress is applied, after an instantaneous elastic response, the strain will continue to increase with time. This phenomenon is called creep and is illustrated in Fig.2.10(a). On the other hand, when a fixed strain is applied (e.g., by stretching a member and then fixing its ends), the stress in the member will decrease with time (Fig.2.10(b)). This phenomenon is called relaxation. If creep and relaxation are linear (e.g., if the stress is doubled, the strain at a particular time is also doubled), we can define the following two parameters: Creep compliance, J(t) = (t)/ Relaxation modulus, Er(t) = (t)/ The creep compliance can be obtained from a test with a fixed load applied to a specimen. Knowing J(t), the time dependent behaviour of the material under arbitrary loading history can be obtained from superposition (see section 2.3.5). (a) (b) creep strain instantaneous elastic strain Time Time Fig.2.10 (a) Creep Behaviour, (b) Relaxation Behaviour For materials exhibiting creep behaviour, when a stress is applied, the strain will increase with time. If stress is applied at a slower rate (i.e. over a longer period of time), the resulted strain will be more than that due to a stress applied at a rapid rate. Fig.2.11 shows the loading/unloading behaviour for two general cases. For creeping materials, the loading and unloading curve do not overlap with one another. The area between the two curves (called the hysteresis loop) reflects the energy absorped by the material over a loading/unloading cycle. This energy absorption varies with loading rate, and is highest at intermediate loading rate. 18 High Loading rate Intermediate Loading Rate Low Loading Rate Fig.11 Hysteresis Behaviour under High and Low Loading Rates 2.3.2 Implications to Structural Design When materials exhibit time dependent behaviour, it will affect structural behaviour in a number of ways. The important effects of time behaviour are summarized below: (1) Due to creeping effects, the long term deformation of structures may be significantly above the short term deflection. Therefore, we should provide enough allowance between panels and other attachments to the primary structure. For large structure, the long term differential creep in different parts of a structure needs to be checked to ensure no problems will be caused. (2) The hysteresis loop as shown in Fig.2.11 indicates that energy can be absorbed during cyclic loading. The energy absorption results in damping of a structure as it is set under vibration (e.g., during an earthquake or typhoon). Note that the damping is frequency dependent, although this is often not considered in civil engineering designs, as damping is difficult to quantify in practice. (3) In prestressed concrete design, the creeping of concrete and relaxation of steel can lead to the loss of prestress. This has to be accounted for in design, and in some cases, re-stressing of the prestressed tendon has to be carried out. (4) Relaxation of a restrained member may lead to stress reversal. This is best illustrated by Fig.2.12, which shows a beam between two very stiff walls. As temperature increases, the beam tends to expand but its expansion is restrained by the walls. With this restraint, the beam is put under compression. Keeping the beam at the high temperature, it will eventually relax to a lower stress level. On cooling, the walls prevent the beam from contracting. As a result, tension is introduced. 19 Beam Stiff Walls Fig. 2.12 A Beam constrained by Stiff Walls 2.3.3 Physical Basis of Time Dependent Behaviour Time dependent behaviour is due to the need of time for atoms or molecules to rearrange themselves under load. For example, when a polymer is under stress, the polymeric chains tend to slide relative to one another. A finite time is required for the chains to go from one state (i.e., a given arrangement) to another. When loaded for a longer time, more movement will be resulted, leading to the phenomenon of creep. Relaxation can be explained in a similar way. When a strain is suddenly applied, there is little time for the polymer chains to move relative to one another. Most of the strain is then carried by the polymer chains themselves, resulting in high stress. As time progresses, the relative movement between the chains allows them to relax. The stress will then be significantly reduced. The rate at which molecular re-arrangement can occur depends on the thermal energy of the molecules. As temperature increases, the energy also increases and creeping (or relaxation) occurs at a higher rate. For metals and ceramics, the significance of creeping can be assessed by looking at the homologous temperature defined by T/T m, where T is the current temperature and Tm is the melting point of the material. Both temperatures should be measured in the absolute scale (i.e., degree C plus 273). If T/Tm > 0.3 - 0.4 for metals, or if T/Tm > 0.4 - 0.5 for ceramics, creeping will start to become important. For polymers, the melting point is not well defined. Creeping becomes significant when the temperature goes above the glass transition temperature (TG) of the material. Physically, this is the temperature above which the van der Waal’s forces between polymer chains start to break. In other words, the chains start to slide after TG is exceeded. Creep and relaxation behaviour then comes into the scene. At room temperature, common materials that may creep significantly include concrete, wood, most polymers as well as lead, tin and glass. In general, the creep rate (i.e., the rate of strain increase under a given stress) increases with applied stress. Creep behaviour is not necessarily linear. For many metals and ceramics, the creep rate at high temperature is proportional to the stress raised to a high 20 power. However, at room temperature and working stress levels, the creep strain of many common materials (polymers, wood, concrete) are linearly dependent on stress. In such a case, material behaviour can be described by models combining springs and dashpots. The studying of these models will constitute the subject matter of the next section. 2.3.4 Modelling of Creep at Low Temperature (Viscoelastic Models) Models with spring and dashpots can be used to describe linear creep behaviour. The spring (Fig.2.13(a)) is a linear elastic element with direct proportionality between stress and strain. For the dashpot (Fig.2.13(b)), the rate of straining is directly proportional to the applied stress. This is similar to the behaviour of viscous liquid, the strain rate of which is directly proportional to the applied shear stress. Since the material can be considered as a combination of linear elastic and viscous elements, it is called a linear viscoelastic material. (a) Spring (b) Dashpot = /E d/dt = Fig. 2.13 Spring and Dashpot for the Modelling of Viscoelastic Behaviour Using one spring and one dashpot, two different models can be created by putting the elements either in series or in parallel. The behaviour of each of these simple models will be studied below. (I) Maxwell Model: (Spring and Dashpot in Series) E Fig.2.14 Maxwell Model In the Maxwell model, the material is considered to be made up of two parts in series. The elastic (time independent) part is represented by a spring with modulus E, and the viscous (time dependent) part is represented by a dashpot of viscosity . The equation relating stress and strain (as well as time) for this model is dervied below. Under an applied stress , the strain in the spring (1) and the strain rate are given by: 1 = /E ; d1/dt = (1/E) d/dt 21 The strain rate in the dashpot is given by: d2/dt = / The total strain, , is the sum of strain in the elastic and viscous parts. = 1 + 2 ; d/dt = d1/dt + d2/dt which gives: (1/E) d/dt + /= d/dt as the governing equation for the material. (1) Creep Behaviour under constant stress applied from 0 < t < t1 Under constant stress, d/dt = 0 d/dt = /; = (/t+ (0) It takes finite time for the dashpot to respond to loading. Therefore, at t = 0, (0)= 0 and the dashpot acts as if it is rigid. The initial strain is then resulted from the spring alone. (0) = /E ; = /E + (/t At t = t1, the load is completely removed. The spring shortens by an amount equal to /E. The remaining strain is (/t1. After load removal, = d/dt = 0, implying d/dt = 0. The strain will stay constant for t > t1. The stress and strain are plotted against time in Fig.2.15 below. t1 t t t1 Fig.2.15 Creep Behaviour under Constant Stress for the Maxwell Model (2) Relaxation Behaviour (Constant Strain applied at t = 0) Under constant strain, d/dt = 0. The governing equation gives: (1/E) d/dt = - / Integrating both sides, and noting that (0)= E (dashpot stays undeformed) at t = 0, we have: = E exp(-Et/) 22 t t Fig.2.16 Relaxation Behaviour of the Maxwell Model (II) Kelvin-Voigt Model (Spring and Dashpot in parallel) E Fig.2.17 Kelvin-Voigt Model For this model, the spring and dashpot are put under the same strain . Stress in the spring: 1 = E Stress in the dashpot: 2 = d/dt The total stress (), which is the sum of 1 and 2, is related to through: d/dt + E = The above is the governing equation for the Kelvin-Voigt model. (1) Creep Behaviour under constant stress applied from 0 < t < t1 The governing equation is a first order differential equation, which can be solved by the following procedure: Multiplying each side of the governing equation by exp(Et/), we have d/dt exp(Et/) + (E/) exp(Et/) = () exp(Et/), The left hand side of the equation can be written as: d [ exp(Et/)]/dt. Carrying out the integration, and noting that (0) = 0 (because the dashpot takes a finite time to respond), the strain is given by: = (/E) [1 - exp(-Et/)] If the stress is removed at t = t1. Then = 0 for t > t1. The governing equation becomes: d/dt = - E Integrating, with (t1) at t = t1 as the initial condition, gives: 23 (t1) exp[-E( t - t1)/] The behaviour is illustrated in Fig.2.18 t1 t t t1 Fig.2.18 Relaxation Behaviour of the Kelvin-Voigt Model (2) Relaxation Behaviour (Constant Strain applied at t = 0) At t = 0, dashpot is theoretically rigid. In other words, the strain should be zero. To force the strain to reach a finite value, infinite stress is required. For t > 0, the strain is constant, implying d/dt = 0. The governing equation gives = E. The relaxation response is shown in Fig.2.19. Infinite stress at t = 0 t t Fig.2.19 Relaxation Behaviour of the Kelvin-Voigt Model In describing the creep/relaxation behaviour of real materials, each of the two models above has its own shortcomings. For the Maxwell model, the strain rate is constant, and after stress is removed, there is no time-dependent gradual strain recovery. For the Kelvin-Voigt model, no instantaneous material response is allowed, thus producing the artifact of infinite stress when a finite strain is suddenly applied. For real materials, applied stress is always accompanied by an instantaneous response. Subsequently, the strain will increase with time but at a decreasing rate. After stress is removed, part of the strain is recovered immediately, while another part will be slowly recovered after a period of time. To describe the behaviour of real materials, the two simple models can be combined as in Fig.2.20. This combined model is called the Burger’s body and can be used to describe the time-dependent behaviour of both concrete and wood. 24 1 E1 2 Instantaneous Response Steady State Creep Transient Response Transient Steady State Response Creep Instantaneous Response t Fig.2.20 The Burger’s Body and its Response to Constant Stress 2.3.5 Strain Response under Arbitrary Stress History - Superposition The creep strain for a unit stress, or creep compliance J(t), can be obtained experimentally from a single test (under constant stress). Once the compliance is known, the creep behaviour under a non-constant stress can be obtained by superposition as illustrated in Fig. 2.21. To apply superposition, any increase in stress level is replaced by a new constant stress applied at the time when stress change takes place. Decrease in stress level is replaced by the removal of a constant stress. In the figure, the stress is shown to increase by discrete amounts. For a continuously changing stress, the stress history can be approximated with discrete stress increments occurring over very small time steps. This is the same principle behind numerical integration. 1+2 2 1 1 3 t 1+2-3 t Fig.2.21 Illustration of the superposition principle 25 2.4 FRACTURE AND FATIGUE 2.4.1 Introduction Fracture is the failure of materials due to the propagation of a crack. In the discussion of ductile behaviour, we have mentioned that the final failure in tension is due to fracture after the onset of necking. In such a case, a large elongation can be observed before final fracture takes place. We are therefore given plenty of warning. In many materials, however, failure occurs by fast fracture. When loading increases, the material (and hence the structure) behaves in an elastic manner. Then, fracture suddenly occurs without any warning. This failure mode, referred to as brittle failure, is exhibited by many common materials such as glass, rock and plain concrete. (Note: due to the presence of aggregates that act as bridges in the crack, fracture in concrete is often considered “quasi-brittle”. This will be further discussed in a later chapter.) Moreover, even for materials that normally behave in a ductile manner (e.g., steel, especially high strength steel), fast failure may occur under some circumstances. Indeed, the unexpected fracture failure of tanks, bridges and ships earlier in this century has resulted in a series of investigations leading to the present day understanding of fracture processes. Fast fracture is due to the sudden propagation of a crack inside a structural component at a load level below that required for yielding of a complete cross section. (Otherwise, yielding will occur instead.) Cracks pre-exist in many materials due to a number of reasons. When solid materials are formed, the densification may not be perfect. Trapped air in the molten or liquid state can turn into pores and cracks in the solidified material. During handling of materials, such as transportation of structural components and their installation, surface damages can be introduced. One common example is the scratch on the surface of window glass. When members are welded together, cracks may form around the weld due to residual stresses and phase changes in the material (this will be further discussed in the Steel chapter). Also, under repeated loading, cracks may nucleate in materials and grow larger with each loading cycle. The slow growth of crack in this manner is referred to as fatigue crack growth. In the following, the physical basis of fracture and a simple way to model fast fracture are first described, followed by a discussion of the various parameters affecting the change in failure mode. Then, our focus will turn to the studying of fatigue. Material fatigue leads to the gradual weakening of structural members and can often convert the failure mode from 26 ductile to brittle. An understanding of fatigue is therefore essential in the assessment of longterm safety of structures. 2.4.2 Fast Fracture: Physical Basis and Modelling When loading is applied to a material, the stress at the tip of a sharp crack is infinite if elastic behaviour is assumed. Since no real material can stay elastic at very high stress levels, an inelastic zone will always be present in front of the crack tip (see Fig.2.22). In metals, inelastic behaviour is due to material yielding. For concrete, this is due to the formation of micro-cracks in front of the main crack. When the load is increased, the inelastic zone grows in size. Ultimately, the crack will propagate suddenly at a very high speed. An important question to address is: what is the criterion for fast fracture to occur? Loading Direction Stress Crack Critical Stress Inelastic Zone Distance from Crack Tip Fig.2.22 Stress Distribution and Inelastic Zone in front of a Sharp Crack To answer the above question, we need to consider the energy balance of a system when crack propagation occurs. Crack propagation requires energy. When a crack extends by a small amount (a) (Fig.2.23), new surfaces are formed. Since atoms on the material surface contain more energy than those in the bulk, surface energy needs to be provided. Also, when the crack propagates, energy is required to extend the inelastic region (see Fig.2.23). 27 Extension of Inelastic Zone additional Crack Area formed due to Crack Propagation Fig.2.23 Energy Absorbing Mechanisms during Crack Propagation To see where the required energy may come from, we can look at the structural component after the crack has propagated by a small amount (Fig.2.24). With a slightly larger crack, the component becomes less stiff (i.e., it is easier to deform). If it is fixed on both ends, the stress will decrease all over the member and energy is released (Fig.2.24a). If it is under fixed load, the displacement at the loading points will increase (Fig2.24b). Additional work is therefore done on the member. Part of the work is converted into additional strain energy stored in the member (Note: in this case, the strain in the uncracked part of the member increases and more energy is stored). The rest is available for extending the crack. In summary, for the two limiting cases described above, and all other cases in between, crack propagation will be accompanied by a release of energy from the system. If this energy is sufficient for the formation of new surfaces and the extension of the inelastic zone, fracture will occur. (a) Load (b) Before Crack Propagation Energy Release d After Crack Propagation Displacement Load P Work Done = P Before Additional Energy Stored = P After Displacement Fig.2.24 Energy Changes as Crack Propagation occurs Under general conditions, the mathematical modelling of the fracture process is very difficult. However, if the inelastic zone is much smaller in size than the specimen, we can define a parameter called critical energy release rate (Gc) and use the following fracture criterion: Fracture occurs when: G = Gc, 28 where G is the energy release rate of the system under a given loading condition, which can be obtained in terms of the applied load and the specimen geometry. In many cases, instead of calculating G, we compute a parameter K defined by K = (EG)1/2. The fracture criterion is then converted into the form: Fracture occurs when: K = Kc = (EGc)1/2 K is a parameter of physical significance because it characterizes the stress concentration in front of the crack tip (Fig.2.25). Along the crack direction, the tensile stress (acting perpendicular to the crack) is given by: = K/(2r)1/2 where r is the distance from the crack tip. K is called the stress intensity factor. K c is called the critical stress intensity factor or simply the fracture toughness of the material. Loading Direction Stress = K 2r Distance from Crack Tip, r Fig.2.25 Variation of Stress in front of Crack Tip Values of K have been obtained for many common loading configurations. Some examples are given in Fig. 2.26. Kc is a material parameter (i.e., it stays the same for the same material) and can be obtained from standard specimens in the laboratory. 29 P W W a 2a P/2 S P/2 K = a (sec a )1/2 W K= PS BW 3/2 [ 2.9(a/W)1/2 - 4.6(a/W)3/2 + 21.8(a/W)5/2 - 37.6(a/W)7/2 + 38.7(a/W)9/2 ] P W K= a P BW 1/2 [ 29.6(a/W)1/2 - 185.5(a/W)3/2 + 655.7(a/W)5/2 - 1017(a/W)7/2 + 63.9(a/W)9/2 ] P Fig.2.26 Stress Intensity Factor for a few Common Loading Configurations 2.4.3 Failure of Metal: Ductile or Brittle As we mention earlier, metals can sometimes fail in a brittle manner. In this section, we will look at the various factors affecting the failure mode of metals. (Note: similar arguments can be made for other materials though the analysis is often more complicated.) Consider a steel plate with a small internal crack of size 2a, under uniform tensile stress. If the width W is very large compared with 2a, sec(2a/W) is very close to unity. The stress intensity factor is then given by (see Fig.2.26): K = (a)1/2 Fast fracture occurs when K=Kc, or at an applied stress of: = F = Kc/(a)1/2 Material failure can also occur in a ductile manner when = y. Gross yielding will then occur over the whole cross section of the material. Whether failure will be brittle or ductile depends on the relative magnitude of F and y. Since F decreases with increasing crack size, for a member with a relatively large crack, failure will be brittle. For a member 30 with a small crack, ductile failure will occur. This is illustrated in Fig.2.27. The transition crack size (aT) is given by: aT = (1/Kc/y)2 Gross Yielding Brittle Fracture y = K c / a aT Crack Size, a Fig.2.27 Transition between Brittle and Ductile Failure Modes The transition crack size is a function of the fracture toughness and yield strength of the material. For a tough metal with low yield strength, the failure can stay ductile at a larger crack size. For strong metals with low toughness, failure is brittle even if only a small crack exists. The transition crack size depends on temperature and strain rate. Yielding is due to the movement of dislocations in the atomic lattice, which requires a finite amount of time. When loading is very rapid, or when temperature is very low (so the atoms are at very low energy levels), it is more difficult for dislocations to move and the yield strength tends to increase. With less yielding, the inelastic zone in front of the crack tip becomes smaller. As the crack propagates, the newly formed inelastic region (shaded area in Fig.2.23) will also be smaller in size. The energy required for crack propagation then also decreases, leading to a lower material toughness. With higher yield strength and reduced fracture toughness, the transition crack size can decrease significantly. In other words, for a given structural member with a fixed crack size, brittle fracture is more likely to occur at low temperatures or under impact loading. With an understanding of the relation between yield strength and fracture toughness, we can also explain why the strengthening of metals (through alloying, for example) will often reduce the fracture toughness. When very high strength metals are used in structures, extra care should be taken to make sure that failure will not occur in a brittle manner (e.g., the structure can be inspected for crack size to ensure that the maximum crack size is below the transition value). 2.4.4 Fatigue - Phenomenon and Empirical Expressions 31 When cyclic loading is applied to a material, failure may occur at a stress much lower than the strength under static loading. This apparent weakening of the material is called fatigue. The strength reduction with the number of load cycles is illustrated in Fig.2.28 with the S-N diagram. This diagram, which can be obtained experimentally, is useful for component design. Once we know the number of load cycles a structural component is expected to endure over its life span, the appropriate strength value can be chosen. It should be noted that the strength approaches a constant value for very large N. This value is called the fatigue threshold. If applied stress is kept below this value, the material can sustain an Strength infinite number of cycles. Number of Cycles, N Fig.2.28 The S-N Curve under Cyclic Loading Besides reading off the strength from the S-N curve, various empirical expressions have been proposed to relate the magnitude of cyclic loading or stress range () to the number of cycles to failure (Nf). Here, is defined as the difference between the maximum applied stress (max) and the minimum applied stress (min). Also, we can define m to be the mean stress during load application. These definitions are illustrated in Fig.2.29. In equation form, they are: = max - min m = (max + min)/2 max m min time Fig.2.29 Definition of terms for Cyclic Loading 32 In the study of fatigue behaviour, we have to distinguish between high cycle and low cycle fatigue. In high cycle fatigue, the applied stress is often low so neither max nor min are high enough to cause gross yielding (in tension and compression respectively). The number of cycles to failure is then high. In low cycle fatigue, one or both of max and min exceed the yield strength. Failure will then occur after a small number of cycles. For high cycle and low cycle fatigue under zero mean stress (m = 0), the following expressions have been proposed: Basquin’s Law for high cycle fatigue: (Nf)a = C1 where C1 and ‘a’ are constants. For common materials, ‘a’ range from about 1/8 to 1/15. Coffin-Manson Law for low cycle fatigue: PL (Nf)b = C2 where C2 and b are constants, with ‘b’ varying between 0.5 and 0.6. After yielding has occurred, the variation of plastic strain (PL), rather than the stress variation itself, is found to govern fatigue behaviour. When the mean stress is non-zero, the number of cycles to failure will decrease for a given stress range. To keep the same number of cycles to failure, the stress range needs to be reduced to m in accordance with Goodman’s Rule: m = ( 1 - |m| / TS ) In the equation, |m| is the absolute value of the mean stress and TS is the ultimate strength in tension. When the magnitude of cyclic loading is not constant, the lifetime can be predicted with Miner’s rule: (Ni/Nfi) =1 where Ni is the number of cycles under and Nfi is the number of cycles to failure under . Physically, the equation means that every time load cycles are applied, a part of the structural life is used. Eventually, when all the lifetime is used up, failure will occur. It should be noted that the expressions presented in this section are all based on experimental data. The constants in Basquin’s law and Coffin-Manson law are dependent on loading configuration (e.g., direct tension-compression or bending) as well as specimen type (e.g., rod vs plate). These empirical laws are useful when a component is tested in the same way as it will be used in practice. For example, the fatigue results for a steel reinforcing bar under direct tension and compression can be used directly in practice because this is the way a reinforcing bar will be loaded in a real structure. In more general cases, the prediction of 33 fatigue failure requires an understanding of the fatigue process. This will be the focus of the next section. 2.4.5 Physical Basis of Fatigue and K-Based Modelling For an initially uncracked component, the formation of cracks under cyclic loading is illustrated in Fig.2.30(a). At locations of stress concentrations (e.g. bends, corners), local yielding may occur. Dislocation movements lead to sliding of materials at an angle to the applied stress. In some locations, sliding will lead to the formation of extrusions on the surface while in some other locations, intrusions will be present. An intrusion will act like a sharp notch to initiate the propagation of a crack. The crack, which is originally parallel to the sliding direction, eventually orients itself perpendicular to the applied stress. Fig.2.30(b) illustrates the growth of an existing crack. When the maximum stress is applied, the crack opens. Yielding and the associated material sliding result in the formation of new surface at the crack tip. When stress decreases, the crack starts to close (fully or partially) and the new surface folds forward to extend the crack. Note that the area that can fold forward depends on the difference in crack openings at maximum and minimum stress. This explains the significance of stress range in fatigue behaviour. Slow crack growth under cyclic loading leads to the gradual weakening of a structural component, because the fracture stress decreases with crack size. Also, as the crack grows larger, the failure mode may change from ductile to brittle. (b) (a) Extrusions K min Preferred Sliding Direction Intrusions produces a Sharp Notch K max New Surface Formed New Surface Folds Forward Crack Initiated from Notch Tip K min Fig.2.30 Mechanisms for (a) Crack Initiation and (b) Crack Propagation during Fatigue 34 The modelling of crack initiation (Fig.2.30a) is very difficult. However, for many large structures used in civil engineering (such as bridges, storage tanks, pressure vessels, etc), cracks are almost always present at the joints, especially when welding is carried out. We can therefore focus on the modelling of crack propagation. The design strategy is as follows. For a structural component, we calculate (using the approach described in 2.4.3) the critical crack size before fast fracture occurs. Then, after the structure is built, important components are inspected for the initial crack size. If no cracks are found, we use the resolution of inspection as the initial crack size. For example, if the inspection can only reveal cracks 1mm in size or larger, 1 mm is used as a conservative estimate of initial crack size. Knowing the initial and critical crack sizes, the number of cycles to failure can be calculated with the help of Paris’ law, which states: da/dN = A(K)n da/dN is the growth in crack size per unit cycle A and n are constants obtained from experiments K = Kmax - Kmin is the change in stress intensity factor during the loading cycle. Note that K is a function of crack size ‘a’. The equation can be re-arranged in the following form: dN = da / [A(K)n] N goes from zero to Nf when the crack grows from the initial size to the critical. Nf can therefore be obtained through direct integration. ac Nf da n a i [A(K ) ] where ai is the initial crack size and ac is the critical crack size when fast occur occurs under the applied load. 35