File

advertisement

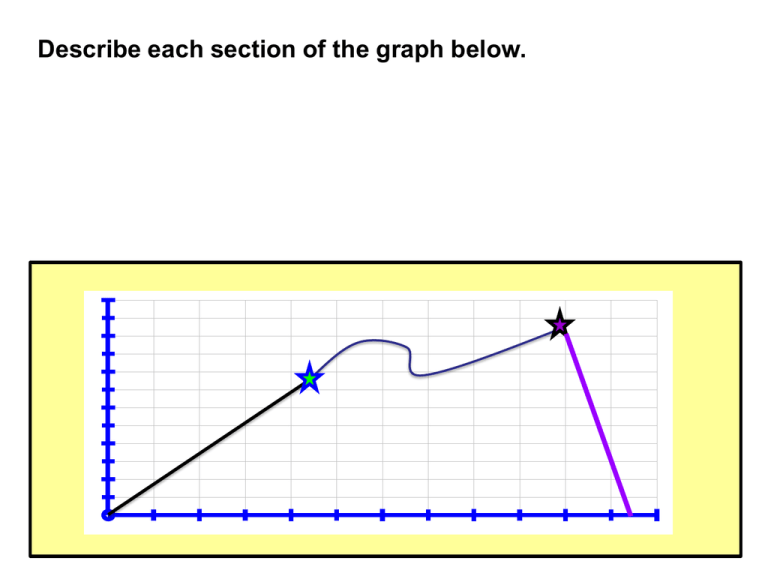

Describe each section of the graph below. 12 10 8 6 4 2 2 4 6 8 10 12 Spring follows Hooke’s law; it has elastic behaviour. Elastic limit is reached, it is permanently deformed. Spring shows plastic behaviour; little force causes big extension. Spring has reached its ultimate tensile stress (UTS). Spring has reached its breaking point and snaps. 12 10 8 6 4 2 2 4 6 8 10 12 2.5 Graphs - Materials Topic 2 Materials Describing Materials Young modulus of a material describes its stiffness. Spring constant of a material describes its elasticity. Stress describes the strength of a material through its ability to withstand applied pressure. UTS describes the maximum stress a material can take before snapping. Strain describes the materials ability to withstand deformation. Behaviour of Materials Brittle behaviour means the material will snap after reaching its elastic limit. Ductile behaviour means the material is durable and has a high plastic region. Plastic behaviour means the material has exceeded its elastic limit and it is now permanently deformed. Small stress will result in large strain. Elastic behaviour means the material obeys Hooke’s law and will return to its original length once the load is released, assuming the elastic limit hasn't been exceeded. Material Graphs Stress - strain graph is used to show the deformation of a material. 12 10 8 Gradient of a stress – strain graphs gives you the Young modulus. 6 4 2 2 4 6 8 10 12 The area gives you the elastic energy stored per unit volume (½σε). Force – extension graph is used to show elastic behaviour. Gradient gives you the spring or force constant. 12 10 8 6 4 The area of the graph gives you the stored elastic potential energy (½Fe) . 2 2 4 6 8 10 12 Properties of Material - Brittle Brittle materials, such as a brick, can sustain a lot of stress. 12 10 8 It has a high spring constant. 6 4 2 2 4 6 8 10 12 After it has reached its elastic limit, it snaps. Brittle material stores very little elastic potential energy. 12 10 8 Loading and unloading is proportional to extension. 6 4 2 It does not have a plastic region. 2 4 6 8 10 12 Properties of Material - Ductile Ductile materials, like copper, can be drawn into a wire. 12 10 8 These materials have a large plastic region 6 4 2 2 4 6 8 10 12 Ductile materials are durable. Extension for a ductile material is the same for loading and unloading. 12 10 It will go back to its original length when all load is removed. 8 6 4 If elastic limit is exceeded, unloading will be parallel to loading but it will be permanently deformed. 2 2 4 6 8 10 12 Properties of Material - Polythene Polythene material, such as rubber, has a high strain percentage. 12 10 8 It reaches it’s elastic limit quite easily. 6 4 2 2 4 6 8 10 12 It has a high UTS, which means after a while, it is difficult to stretch. Extension isn't proportional due to the atomic arrangement of particles. Its extension when unloading is greater than loading. If its elastic limit is exceeded, the extension while unloading will be proportional. 12 10 8 6 4 2 2 4 6 8 10 12 Question 1 To describe deformation of a material, we use a stress – strain graph instead of force – extension graph. Explain why. Question 2 After exceeding the elastic limit, less energy is retrieved when unloading from a ductile material. Explain why. Question 3 Explain why the loading and unloading graph for polythene is peculiar. Question 4 Force – extension graph for polythene can be broken into three segments. Explain each segment of this graph.