DAY 3 - Rose

advertisement

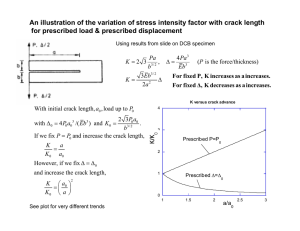

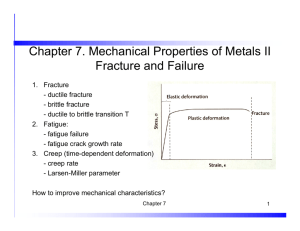

MATERIALS ENGINEERING – DAY 3 Quick Review of Hardness & Hardness Testing Big problem: when ductile materials go brittle… Impact Testing Ductile to Brittle Transition Temperature Introduction to Fracture. See how far we get. REVIEW What is the most common type of material test? What does it measure? STRESS CONCENTRATION What is it? Changes in geometry (holes, fillets, threads, notches) can cause local increases in stress (stress raisers) For example: Near a small hole in a large plate, the stress at the edge of the hole is three times as high as the stress away from the hole. MORE ON STRESS CONCENTRATION FACTOR Importance: 1. high-strength, low ductility materials can crack 2. cyclic stress coupled with stress concentration is typical for fatigue failures Quantifying: Stress Concentration Factor, K=smax/snominal where: K is from published charts snominal is the stress ignoring the stress concentration smax is the highest local stress due to the concentration WHEN “GOOD” MATERIALS GO “BAD” The Schectady. Here is the result. These points need mentioning: 1. Steel in the vessel had performed well in tension and hardness testing in non-service environment. 2. Many, many ship failures of this type took place in WWII. Here’s another. The John. P Gaines. 3. The Navy had to change material specifications. There was a major research effort. Here’s one result. TEST TO MEASURE NOTCH TOUGHNESS 1. 2. 3. The following factors affect toughness Tri-axial stress state Presence of a notch or stress concentration Cold Temperature Therefore, a test was designed to probe the materials performance under these more demanding conditions. CHARPY TESTS AND IZOD Specimen Test Apparatus Result: Notch toughness CHARPY TEST Measures the energy to break, usually of a notched specimen Energy (ft-lb, J) FCC no transition Hammmer Upper Shelf (ductile) BCC Supports Lower Shelf (brittle) Temperature Ductile-Brittle Transition Temp. Charpy Bar DUCTILE TO BRITTLE TRANSITION TEMPERATURE There are several ways of specifying the actual temperature at which transition occurs. One is the highest temp on the lower shelf. Another the temp ½ way between the two shelves. Where was the SS Schnectady? Effect of Radiation on Charpy Energy www.msm.cam.ac.uk/.../Irradiated_Steel.html Cup-and-cone fracture surface of duralumin as a result of failure by necking. www.answers.com/topic/necking The fracture surface of this Charpy impact specimen show that the fracture mode was a mixture of ductile (dull gray) and brittle (shiny, salt and peppery appearance). www.matsci.ucdavis.edu/.../EMS-174L/EMS-174L.htm metallurgist.com/.../Fractography.htm http://pwatlas.mt.umist.ac.uk/internetmi croscope/micrographs/failure/brittlesteel.html IMPACT TESTING Advantages Determine minimum temperature of use Finds “notch sensitive” materials Disadvantages Difficult to apply quantitatively in design Addresses temperature, not stress or flaw size FRACTURE MECHANICS There is another problem, really more severe than a stress concentrator. It is a sharp crack. Clearly, this can make a ductile material act like a brittle material. i.e. sudden, unexpected failure. Since WWII this has been a fertile field of study. It is the science of fracture mechanics which brings together 1. Analytical methods of solid mechanics to calculate stress field around crack 2. Experimental methods to determine resistance to crack propagation INTRODUCTORY EQUATIONS The f’s are functions of q. The variable r measures distance from the crack tip. The variable K is called the stress intensity factor. K Ys a FRACTURE MECHANICS For notched members, failure occurs when KI(applied)>KI(critical). a 2a Importance: Can quantify”strength” of flawed members. Quantifying: KI Ys a Geometry factor stress (nominal) Advantage: •can set inspection standards •can use parts with subcritical flaws Units: ksiin, MPam flaw size Stress Concentration Factor multiplier of nominal stress no units can’t quantitatively predict failure stress Stress Intensity Factor measure of local stress field units of: ksiin, MPam can predict failure stress for discovered flaws STRESS INTENSITY The factor Y depends on crack length and geometry. So, an alternate, and more useful way of talking about crack stability is to frame the discussion in terms of the stress intensity as opposed to the critical strain energy release rate. A crack will become unstable when K = Kc, a critical value called fracture toughness. a Kc Y s c a W The specimen geometry comes in through Y. See Figure 8.13 in the text. EXAMPLE PROBLEM A large, thick plate is fabricated from a steel alloy that has a plane strain fracture toughness of 55 MPA m1/2. If, during service, the plate is exposed to a tensile stress of 200 MPA, determine the minimum length of a surface crack that would lead to failure? Ans. About 24 mm.