CCIntro

MGT 6421 Quality Management II

Introduction to Control Charts

Control charts are the basic tools of statistical process control. They are simple to construct and use, and are very useful at leading to process improvement.

We know that all processes exhibit variation from the target, but how much variation should we tolerate before we adjust the process? In the language of statistical process control, how far can the process deviate from target and still be "in control?"

First we will define some terms:

Common Causes of Variation are those which are due only to random or chance causes. This variation is expected and therefore predictable.

Special Causes of Variation are those which come from influences outside those ordinarily encountered by the system.

Introduction to Control Charts - 1

MGT 6421 Quality Management II

In control, or under statistical control, means that the variable we are measuring is centered on the mean, and its variability is due only to common causes.

Our goal with statistical process control is to differentiate between special and common causes. If we can eliminate special causes, the process will be under statistical control, and will be improved. In addition, the process will be predictable, and further improvements will be possible by finding ways to reduce common causes of variation.

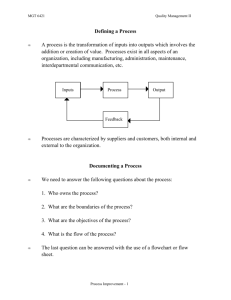

The fundamental relationships in developing control charts are as follows:

The center (or central) line is the mean of the process.

The upper control limit (UCL) is the mean plus 3 standard deviations.

The lower control limit (LCL) is the mean minus 3 standard deviations.

So the limits are

±

3

.

Introduction to Control Charts - 2

2

1

0

-1

-2

-3

-4

-5

5

4

3

MGT 6421 Quality Management II

The reason for using 3 standard deviations is based on the assumption that the process output is normally distributed. If the process is in control, there is a very small probability of an observation falling outside of the control limits. This probability increases as the process deviates from the incontrol state.

UCL center line

LCL

Introduction to Control Charts - 3

MGT 6421 Quality Management II

There are two main categories of control charts:

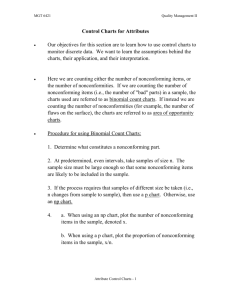

1. Control charts for attributes, which are used when we are counting the number of nonconformities or nonconforming items (i.e., when the variables of interest are discrete).

2. Control charts for variables, which are used when we are making actual measurements (i.e., when the variables of interest are continuous).

Introduction to Control Charts - 4

MGT 6421 Quality Management II

Control Chart Decision Variables

There are several variables that we have under our control when we design control charts. These variables include the control limits, the sample size, and the sampling interval.

We have already discussed the control limits to some degree. The criterion we have discussed uses statistical techniques. There are other criteria that might be considered. One obvious one is economics. Another might be to take into account the actual distribution rather than assuming a normal approximation.

The choice of sampling frequency is often dictated by the process itself.

There are natrual times at which it is relatively easy to measure the process.

Rules of thumb of every hour or every day are often employed. In traditional control chart theory, the sampling interval is assumed to be fixed.

The question of sample size also depends upon the physical process, and usually takes into account questions of economics and statistical theory.

On the economics size, we need to keep the sample size low enough that sampling costs do not become too high. On the statistical side, we need the sample size to be large enough to better detect shifts in the process (which can be translated into an economic problem), and to meet the assumptions of the normal distribution approximation. Again, rules of thumbs have been developed.

Introduction to Control Charts - 5

MGT 6421 Quality Management II

Rational Sampling

Sampling for control chart construction is quite different from sampling for traditional statistical analysis. With control charts, we are working with what Deming called analytic studies (he called traditional statistical studies enumerative studies). The main difference is that we are collecting and analyzing data over time, rather than at one fixed interval.

As a result, we need a sampling method that will allow us to detect changes over time. Hence, we want the within-group variation to be small, and the between-group variation to be large. It is the between-group variation that we see on the control chart.

The type of sampling that is used in control chart construction is called

“rational sampling,” and the resulting samples are called “rational samples” or “rational subgroups.” These rational subgroups are formed by inspecting several ( n ) units in a row taken from the process at a particular point in time. Then, after the sampling interval has passed, another n units in a row are taken from the process.

Introduction to Control Charts - 6

MGT 6421 Quality Management II

Out-of-Control Patterns

Observations lying outside of 3 standard deviations are not the only type of aberration which suggests an out-of-control condition. Any deviation from randomness or normality suggests that the process may be out of control.

If the process output is normally distributed and independent, we expect most of the points to be near the center line, some points near the control limits, no points outside the control limits, and no runs or trends.

Other rules have been developed to identify these other types of out-of- control patterns. Some of these rules are summarized on the following page.

In order to determine the zones mentioned, I suggest the following: a.

First obtain the standard error by taking the difference between the UCL and the center line, and divide by 3. b.

Then the zone C boundaries are the center line ± one standard error and the zone B boundaries are the center line ± two standard errors.

Introduction to Control Charts - 7

MGT 6421 Quality Management II

From Nelson, L. S. (1984), "The Shewhart Control Chart--Tests for Special Causes," Journal of Quality Technology , Vol. 16, No. 4, 237-239.

Introduction to Control Charts - 8

MGT 6421 Quality Management II

Out-of-Control Conditions

Now we want to talk about their possible causes of the patterns discussed above.

The different rules discussed above can help identify certain kinds of outof-control conditions. We will identify what rules are associated with what condition.

Shifts

A shift indicates a change in the mean of the variable being monitored.

Shifts can be of several types, including sudden shifts and gradual shifts.

Points outside the control limits or points on one side of the centerline indicate sudden shifts. What might cause such a shift?

A trend on a control chart will signal a gradual shift.

Introduction to Control Charts - 9

MGT 6421 Quality Management II

Cycles:

Cycles are repeated patterns. Depending on the agreement between the cycle frequency and the sampling frequency, they can appear as several points on one side of the centerline, points alternating back and forth, or just a repeating pattern (not necessarily covered by any of the rules that we have discussed).

Wild Patterns:

There are two types of these: freaks and bunching. Freaks are single points that are very different from any other points. Points outside the control limits usually detect these. Often they are caused by recording errors. Bunching is similar, but affects more than one point. Normally the points that are affected are close to each other.

Instability Patterns

Instability is characterized by wide swings up and down, with many points being outside of the control limits. These patterns can be caused by disturbances that create wide multimodal distributions in a process variable. One example of such a cause is over adjustment of a machine.

Introduction to Control Charts - 10

MGT 6421 Quality Management II

Mixtures:

Very few points near the centerline or too many points hugging the centerline often characterize mixtures. Mixtures might also be indicated by a “saw-tooth” pattern. Mixture patterns indicate the presence of two or more distributions. An obvious example of this is if we are using two or more suppliers. If we sample separately from the two suppliers, we are likely to see either the saw-tooth pattern or too many points near or beyond the control limits.

I f we combine the supplies from the two samples, then the expected pattern would be too many points near the centerline. This is called stratification.

Example:

Below are some simulated data of two suppliers. The parts from the suppliers are mixed to form batches of 100.

Supplier 1 n=50, p=.8

38

41

36

39

39

34

40

39

39

40

37

32

36

37

45

38.13

0.76

Supplier 2 n=50, p=.01

0

0

0

0

2

1

2

0

0

0

0

0

0

0

0

0.33

0.0067

Mixture

(n=100)

38

41

36

39

41

35

42

39

39

40

37

32

36

37

45

38.467

0.38467

Introduction to Control Charts - 11

MGT 6421 Quality Management II

High defect np chart

40

35

30

25

20

50

45

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Mixture np chart

55

50

45

40

35

30

25

20

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Introduction to Control Charts - 12

MGT 6421 Quality Management II

Control Chart Following:

If observations come from a normal distribution, the sample variability

(measured by the standard deviation or the range) and the mean are independent. In other types of distributions, however, this may not be the case. Hence if the patterns on the X and R (or s) charts follow each other, it may be an indication that we are sampling from a skewed distribution.

Introduction to Control Charts - 13