Control Chart Performance

advertisement

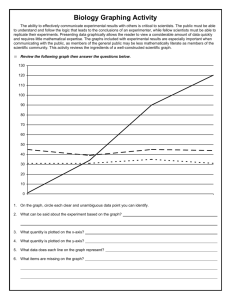

MGT 6421 Quality Management II Control Chart Performance When selecting control charts, we should be interested in how effective they are. Our objectives for today are to know how to measure the effectiveness of the charts we have discussed. There are two commonly used methods for comparing control chart performance. The first method is to determine the charts operating characteristic (OC) curve. The second is to determine the average run length (ARL). The OC Curve: The OC Curve shows the probability that an observation will fall within the control limits given the state of the process. This is very much like finding power curves in hypothesis testing. For example, for the X chart, we can find the probability of being within the limits (Pa) for particular values of the process mean: Pa P( LCL X UCL|) . Implementation and Performance - 1 MGT 6421 Quality Management II The curve is generated by calculating Pa for different values of . Below we calculate the operating characteristic curve for the X chart when the standards are known. In this case the control limits are 0 3 . We will n let the mean shift in increments of the standard deviation of X (i.e., 0 ). If this is the case, then n Pa P 0 3 X 0 3 n n 0 , so n 0 3 0 3 0 0 n n X n n Pa P n n n or Pa = P(-3- Z 3-). Example: Implementation and Performance - 2 MGT 6421 Quality Management II The table below shows some values of Pa for different values of . The OC curve is also drawn. 0 n 0 2 n 0 3 n 0 1 Pa 0.9973 0.9772 0.8413 0.5000 1.0000 0.9000 0.8000 0.7000 0.6000 Pa 0.5000 0.4000 0.3000 0.2000 0.1000 0.0000 0 1 2 3 Implementation and Performance - 3 4 5 6 MGT 6421 Quality Management II The Run Length Another measure of performance that is closely related to OC curve values is the run length. The run length is a random variable and is defined as the number of points plotted on the chart until an out-of-control condition is signaled. The beginning point at which we count the number of plotted points depends on whether we are finding the in-control run length or the out-of-control run length. The in-control run length measures the number of plotted points from the beginning of the monitoring period until an out-of-control signal, given that there have been no changes in the process. We want the average in-control run length to be high. The out-of-control run length measures the number of plotted points from the time of a process change until an out-of-control signal is given. Its value depends upon the size of the shift. We want the average out-ofcontrol run length to be small. Assuming that the statistic being plotted is independent over time (i.e., one plotted point is independent of other plotted points), the run length follows a geometric distribution. Implementation and Performance - 4 MGT 6421 Quality Management II The Average Run Length The average run length (ARL) is the average number of points plotted on the chart until an out-of-control condition is signaled. It is the expected value of the run length distribution. It is related to the OC curve as follows: ARL 1 . 1 Pa For our example: Implementation and Performance - 5 MGT 6421 Quality Management II The ARL is probably used more often in control chart literature than OC curve values, because it is conceptually easier to understand. The table below1 shows the ARL values for the X chart, both with and without run rules*. Shift 0 1 2 3 * Rule 1: Rule 2: Rule 3: Rule 4: Rule 1 370.4 43.89 6.3 2 Rules 1 & 2 225.44 20.01 3.65 1.68 Rules 1, 2 & 3 132.89 10.95 3.14 1.67 Rules 1, 2, 3 & 4 91.75 9.22 3.13 1.67 One observation outside the control limits Two of three outside of 2 standard deviatioins Four of five outside of 1 standard deviatioin Eight in a row on one side of the center line. Example: 1 The source for these numbers is Champ, W.C., and Woodall, W. H. (1987). "Exact Results for Shewhart Control Charts With Supplementary Runs Rules," Technometrics, Vol. 29, No. 4, 393-399. Implementation and Performance - 6 MGT 6421 Quality Management II ARL with Attribute Control Charts We can also apply the ARL idea to attribute control charts. The principles are all the same. All that changes are the probability computations. Examples: Implementation and Performance - 7 MGT 6421 Quality Management II Probability Limits We can also use the idea of OC curves with attribute control charts to design limits that better meet the assumptions of the statistic being plotted. In other words, the charts that we have discussed to this point all use 3sigma limits. But if the binomial or poisson distributions are not close to a normal distribution, the probability of a type I error may be far from .0027. Hence we desire to design control charts that have smaller type I errors (or alternatively, that have better in-control ARL values). Examples: Implementation and Performance - 8