5 HOW SPC WORKS

advertisement

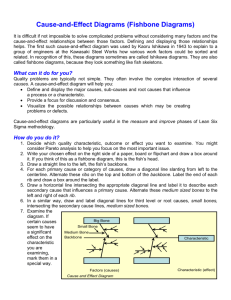

5 HOW SPC WORKS BASIC SPC TOOLS • SPC is a powerful collection of problem-solving tools useful in achieving process stability and improving capability through the reduction of variability. SPC can be applied to any process. Its seven major tools, known as “the magnificent seven” are • SPC builds an environment in which all individuals in an organization seek continuous improvement in quality and productivity. • This environment is best developed when the management becomes involved in the process •A certain amount of inherent or natural variability always exists in a production process regardless of how well designed or carefully maintained it is. •This variability is known as natural variability or ‘background noise’. •It is the cumulative effect of many small essentially unavoidable causes. Also known as ‘stable system of chance causes’. •A process is operating with only chance causes of variation present is said to be in statistical control. It is the rock bottom variation which s always there and can be reduced by changing the process. • Other types of variability may occasionally be present in the output of the process. • Following are the sources of variability: • Improperly adjusted or controlled machines • Operator errors • Defective raw material • Such variability is known as ‘assignable causes’ and are large as compared to background noise • A process that is operating in the presence of assignable causes is said to be out of control. • NO PROCESS IS STABLE FOREVER • The major objective of SPC is to quickly detect the causes of the process shift so the investigation of the process and corrective action may be taken before any nonconforming units are made. • A graphical display of quality characteristics that has been measured or computed from a sample versus the sample number or time • A control chart contains – A center line • Represents the average value of the quality characteristics according to the in control state – An upper control limit – A lower control limit • All sample points fall between these points if the process is in control – No action is necessary A point that plots outside the control limits is evidence that the process is out of control – Investigation and corrective action are required to find and eliminate assignable cause(s) • If the process is in control, all the plotted points should have an essentially random pattern. If they behave in a systematic or non random manner then this could be an indication that the process is out of control. • There is a close connection between control charts and hypothesis testing- point falling within the control limit. • A point plotting within the control limit is equivalent to failing to reject the hypothesis of statistical control, and a point plotting outside the control limits is equivalent to rejecting the hypothesis of statistical control. Photolithography Example • Important quality characteristic in hard bake is resist flow width • Process is monitored by average flow width – Sample of 5 wafers – Process mean is 1.5 microns – Process standard deviation is 0.15 microns • Note that all plotted points fall inside the control limits – Process is considered to be in statistical control Shewhart Control Chart Model • Root cause for assignable causes should be identified and eliminated. Cosmetic solutions will lead to only short term corrections. • A very important part of the corrective action process associated with control chart is OCAP( out of control action plan ). • It’s a flow chart consists of checkpoints, which are potential assignable causes, and terminators, which are actions taken to resolve the out of control condition. Sample size and the sampling frequency • The greater the sample size is the greater the probability of detecting the small shifts in the process. • Small samples at short intervals or large samples at large intervals. Current practice in the industry is to take small samples at short intervals. • Another way regarding sampling frequency and sample size is through ARL ( average run length) • ARL = 1/p, where p is the probability that any point exceeds the control limit • e.g with 3 sigma limits, p = 0.0027 is the probability that a single point fall outside the control limits. • ARL = 1/ 0.0027 = 370,which means an out of control signal will be generated after 370 samples on average, even is the process is in control Analysis of Patterns in Control Limits • Even if all the points fall within limits, the points may not indicate statistical control if they do no follow the random pattern. • In a non- random pattern, if the points have an increasing trend over a number of samples, we would call this run up, on the other hand run down. The WECO Rules • • To identify the non random patterns of the control chart, The Western Electric Handbook suggests a set of decision rules. The process is out of control if : 1. 2. 3. 4. One point plots outside the 3-sigma control limit. 2 out of three consecutive points plot beyond the 2- sigma warning limits Four out of five consecutive points plot at a distance of one sigma or beyond from the center line Eight consecutive points plot on one side of the center line 4-4 THE REST OF THE “MAGNIFICENT SEVEN” 1. 2. 3. 4. 5. 6. 7. Histogram or stem-and-leaf plot Check sheet Pareto chart Cause-and-effect diagram Defect concentration diagram Scatter diagram Control chart Check sheet • Check sheet can be very useful in collecting either the historical or current data in the early stages of production. • The time oriented summary of data is helpful in looking for trends or other meaningful patterns. Procedure • Decide what event or problem will be observed. Develop operational definitions. • Decide when data will be collected and for how long. • Design the form. Set it up so that data can be recorded simply by making check marks or Xs or similar symbols and so that data do not have to be recopied for analysis. • Label all spaces on the form. • Test the check sheet for a short trial period to be sure it collects the appropriate data and is easy to use. • Each time the targeted event or problem occurs, record data on the check sheet. Pareto chart • It id simply the frequency distribution of attribute data arranged by category. • Most useful of the ‘magnificent seven’. • It identify the most frequent defects, but not the most important. • To identify the most important there are two methods which can be used: – Use the weighting scheme to modify the frequency counts. – Accompany the frequency Pareto chart analysis with the cost or exposure Pareto chart. Pareto Chart Cause-and-Effect Diagram • Once a defect, error, or problem has been identified, potential causes of this undesirable effect has to be analyzed. • It is a formal tool to unlayer such causes. Cause-and-effect diagrams • Cause-and-effect diagrams are also called: – Ishikawa diagrams (Dr. Kaoru Ishikawa, 1943) – fishbone diagrams • Cause-and -effect diagrams do not have a statistical basis, but are excellent aids for problem solving and trouble-shooting • Cause-and-effect diagrams can – reveal important relationships among various variables and possible causes – provide additional insight into process behavior Cause-and-Effect Diagram Defect Concentration Diagram Scatter Diagram