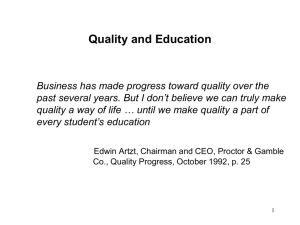

Lecture on quality control

advertisement

ISEN 220 Introduction to Production and Manufacturing Systems Dr. Gary Gaukler Quality and Profit Profit = Revenue – Cost Quality impacts on the revenue side: Quality impacts on the cost side: 6–2 Defining Quality The totality of features and characteristics of a product or service that bears on its ability to satisfy stated or implied needs American Society for Quality 3 6–3 Costs of Quality Prevention costs - reducing the potential for defects Appraisal costs - evaluating products, parts, and services Internal failure - producing defective parts or service before delivery External costs - defects discovered after delivery 4 6–4 Costs of Quality There is a tradeoff between the costs of improving quality, and the costs of poor quality Philip Crosby (1979): “Quality is free” 5 6–5 Inspection Involves examining items to see if an item is good or defective Detect a defective product Does not correct deficiencies in process or product It is expensive Issues When to inspect Where in process to inspect 6 6–6 Inspection Many problems Worker fatigue Measurement error Process variability Cannot inspect quality into a product Robust design, empowered employees, and sound processes are better solutions 7 6–7 Statistical Process Control (SPC) Uses statistics and control charts to tell when to take corrective action Drives process improvement Four key steps Measure the process When a change is indicated, find the assignable cause Eliminate or incorporate the cause Restart the revised process 8 6–8 An SPC Chart Plots the percent of free throws missed 20% Upper control limit 10% Coach’s target value 0% | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 Lower control limit Game number Figure 6.7 9 6–9 Control Charts Constructed from historical data, the purpose of control charts is to help distinguish between natural variations and variations due to assignable causes 10 6 – 10 Statistical Process Control (SPC) Variability is inherent in every process Natural or common causes Special or assignable causes Provides a statistical signal when assignable causes are present Detect and eliminate assignable causes of variation 11 6 – 11 Natural Variations Also called common causes Affect virtually all production processes Expected amount of variation Output measures follow a probability distribution For any distribution there is a measure of central tendency and dispersion If the distribution of outputs falls within acceptable limits, the process is said to be “in control” 12 6 – 12 Assignable Variations Also called special causes of variation Generally this is some change in the process Variations that can be traced to a specific reason The objective is to discover when assignable causes are present Eliminate the bad causes Incorporate the good causes 13 6 – 13 Samples To measure the process, we take samples and analyze the sample statistics following these steps Figure S6.1 Frequency (a) Samples of the product, say five boxes of cereal taken off the filling machine line, vary from each other in weight Each of these represents one sample of five boxes of cereal # # # # # # # # # # # # # # # # # # # # # # # # # # Weight 14 6 – 14 Samples To measure the process, we take samples and analyze the sample statistics following these steps Figure S6.1 Frequency (b) After enough samples are taken from a stable process, they form a pattern called a distribution The solid line represents the distribution Weight 15 6 – 15 Samples To measure the process, we take samples and analyze the sample statistics following these steps Frequency (c) There are many types of distributions, including the normal (bell-shaped) distribution, but distributions do differ in terms of central tendency (mean), standard deviation or variance, and shape Figure S6.1 Central tendency Weight Variation Weight Shape Weight 16 6 – 16 Samples (d) If only natural causes of variation are present, the output of a process forms a distribution that is stable over time and is predictable Frequency To measure the process, we take samples and analyze the sample statistics following these steps Prediction Weight Figure S6.1 17 6 – 17 Samples To measure the process, we take samples and analyze the sample statistics following these steps Frequency (e) If assignable causes are present, the process output is not stable over time and is not predicable ? ?? ?? ? ? ? ? ? ? ? ? ? ?? ? ? ? Prediction Weight Figure S6.1 18 6 – 18 Central Limit Theorem Regardless of the distribution of the population, the distribution of sample means drawn from the population will tend to follow a normal curve 1. The mean of the sampling distribution (x) will be the same as the population mean m 2. The standard deviation of the sampling distribution (sx) will equal the population standard deviation (s) divided by the square root of the sample size, n x=m sx = s n 19 6 – 19 Population and Sampling Distributions Three population distributions Distribution of sample means Mean of sample means = x Beta Standard deviation of s the sample = sx = n means Normal Uniform | | | | -3sx -2sx -1sx x | | | +1sx +2sx +3sx 95.45% fall within ± 2sx 99.73% of all x fall within ± 3sx Figure S6.3 20 6 – 20 Control Charts for Variables For variables that have continuous dimensions Weight, speed, length, strength, etc. x-charts are to control the central tendency of the process R-charts are to control the dispersion of the process These two charts must be used together 21 6 – 21 Setting Chart Limits For x-Charts when we know s Upper control limit (UCL) = x + zsx Lower control limit (LCL) = x - zsx where x = mean of the sample means or a target value set for the process z = number of normal standard deviations sx = standard deviation of the sample means = s/ n s = population standard deviation n = sample size 22 6 – 22 Setting Control Limits Hour 1 Box Weight of Number Oat Flakes 1 17 2 13 3 16 4 18 n=9 5 17 6 16 7 15 8 17 9 16 Mean 16.1 s= 1 Hour 1 2 3 4 5 6 Mean 16.1 16.8 15.5 16.5 16.5 16.4 Hour 7 8 9 10 11 12 Mean 15.2 16.4 16.3 14.8 14.2 17.3 For 99.73% control limits, z = 3 UCLx = x + zsx = 16 + 3(1/3) = 17 ozs LCLx = x - zsx = 16 - 3(1/3) = 15 ozs 23 6 – 23 Setting Control Limits Control Chart for sample of 9 boxes Variation due to assignable causes Out of control 17 = UCL Variation due to natural causes 16 = Mean 15 = LCL | | | | | | | | | | | | 1 2 3 4 5 6 7 8 9 10 11 12 Sample number Out of control Variation due to assignable causes 24 6 – 24 Setting Chart Limits For x-Charts when we don’t know s Upper control limit (UCL) = x + A2R Lower control limit (LCL) = x - A2R where R = average range of the samples A2 = control chart factor found in Table S6.1 x = mean of the sample means 25 6 – 25 Control Chart Factors Sample Size n Mean Factor A2 Upper Range D4 Lower Range D3 2 3 4 5 6 7 8 9 10 12 1.880 1.023 .729 .577 .483 .419 .373 .337 .308 .266 3.268 2.574 2.282 2.115 2.004 1.924 1.864 1.816 1.777 1.716 0 0 0 0 0 0.076 0.136 0.184 0.223 0.284 Table S6.1 26 6 – 26 Setting Control Limits Process average x = 16.01 ounces Average range R = .25 Sample size n = 5 27 6 – 27 Setting Control Limits Process average x = 16.01 ounces Average range R = .25 Sample size n = 5 UCLx LCLx = x + A2R = 16.01 + (.577)(.25) = 16.01 + .144 = 16.154 ounces UCL = 16.154 = x - A2R = 16.01 - .144 = 15.866 ounces LCL = 15.866 Mean = 16.01 28 6 – 28