MMPC Chapter 4

advertisement

Chapter 8: Quality Management

© Holmes Miller 1999

Importance of Quality

Costs & market share

Market Gains

Reputation

Volume

Price

Improved

Quality

Increased

Profits

Lower Costs

Productivity

Rework/Scrap

Warranty

What is quality??

The Concept of Consistency:

Who is the Better Target Shooter?

Not just the mean is important, but also the variance

Need to look at the distribution function

Two Types of Causes for Variation

Common Cause Variation (low level)

Common Cause Variation (high level)

Assignable Cause Variation

• Need to measure and reduce common cause variation

• Identify assignable cause variation as soon as possible

Funnel Experiment (Deming)

Tampering with a stable system only increases the

production of faulty items and mistakes.

Tampering is taking action based on the belief that a common cause

is a special cause.

Improvement of a stable system nearly always means

reduction of variation.

One necessary qualification of anyone in management is --

-- stop asking people to explain ups and downs that come

from random variation.

Statistical Process Control: Control Charts

• Track process parameter over time

- mean

- percentage defects

Process

Parameter

Upper Control Limit (UCL)

Center Line

Lower Control Limit (LCL)

Time

• Distinguish between

- common cause variation

(within control limits)

- assignable cause variation

(outside control limits)

• Measure process performance:

how much common cause variation

is in the process while the process

is “in control”?

Control Charts: The X-bar Chart

• Define control limits

UCL= X +A2 ×R =3.81+0.58*5.85=7.19

LCL= X -A2 ×R =3.81-0.58*5.85=0.41

12

• Constants are taken from a table

10

• Identify assignable causes:

- point over UCL

- point below LCL

- many (6) points on one side of center

8

6

4

2

0

1

3

5

mean

st-dev

7

9

11

13 15 17 19 21 23 25 27

CSR 1

2.95

0.96

CSR 2

3.23

2.36

• In this case:

- problems in period 13

- new operator was assigned

CSR 3

7.63

7.33

CSR 4

3.08

1.87

CSR 5

4.26

4.41

Attribute Based Control Charts: The p-chart

0.180

0.160

0.140

0.120

0.100

0.080

0.060

0.040

0.020

0.000

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

The Statistical Meaning of Six Sigma

Upper

Specification

Limit (USL)

Lower

Specification

Limit (LSL)

Process A

(with st. dev sA)

X-3sA X-2sA X-1sA

X

X+1sA

X+2s

X+3sA

3

Process B

(with st. dev sB)

X-6sB

X

Process capability measure

Cp

USL LSL

6ˆ

x

Cp

P{defect}

ppm

1

0.33

0.317

317,000

2

0.67

0.0455

45,500

3

1.00

0.0027

2,700

4

1.33

0.0001

63

5

1.67

0.0000006

0.6

6

2.00

2x10-9

0.00

X+6sB

•Don’t confuse control limits with specification limits: a process can be in control,

yet be incapable of meeting customer specs

Pareto Analysis

Absolute

Number

Cause of Defect

Percentage

Cumulative

Browser error

43

0.39

0.39

Order number out of sequence

29

0.26

0.65

Product shipped, but credit card not billed

16

0.15

0.80

Order entry mistake

11

0.10

0.90

8

0.07

0.97

3

0.03

1.00

Product shipped to billing address

Wrong model shipped

Total

110

100

Number of

defects

100

75

50

50

Wrong model

shipped

Product shipped to

billing address

Order entry

mistake

Product shipped, but

credit card not billed

Order number out

off sequence

Browser

error

25

Cumulative

percents of

defects

How do you get to a Six Sigma Process?

Step 1: Do Things Consistently (ISO 9000)

1. Management Responsibility

2. Quality System

3. Contract review

4. Design control

5. Document control

6. Purchasing / Supplier evaluation

7. Handling of customer supplied material

8. Products must be traceable

9. Process control

10. Inspection and testing

11. Inspection, Measuring, Test Equipment

12. Records of inspections and tests

13. Control of nonconforming products

14. Corrective action

15. Handling, storage, packaging, delivery

16. Quality records

17. Internal quality audits

18. Training

19. Servicing

20. Statistical techniques

Examples: “The design process shall be planned”,

“production processes shall be defined and planned”

Step 2: Reduce Variability in the Process

Taguchi: Even Small Deviations are Quality Losses

Quality

Quality

Loss

Loss = C(x-T)2

Performance

Metric, x

Good

Performance

Metric

Bad

Minimum

acceptable

value

Target

value

Maximum

acceptable

value

Target

value

•It is not enough to look at “Good” vs “Bad” Outcomes

•Only looking at good vs bad wastes opportunities for learning; especially as failures

become rare (closer to six sigma) you need to learn from the “near misses”

•Catapult: Land “in the box” opposed to “perfect on target”

Step 3: Accommodate Residual Variability

Through Robust Design

A product/process that produces consistent,

high-level performance "despite being

subjected to a wide range of changing client

and manufacturing conditions.

Cause and Effect Diagram (Ishikawa Diagram)

Specifications /

information

Machines

Cutting

tool worn

Dimensions incorrectly

specified in drawing

Vise position

set incorrectly

Clamping force too

high or too low

Machine tool

coordinates set incorrectly

Part incorrectly

positioned in clamp

Dimension incorrectly coded

In machine tool program

Vice position shifted

during production

Part clamping

surfaces corrupted

Steer support

height deviates

from specification

Extrusion temperature

too high

Error in

measuring height

Extrusion stock

undersized

Extrusion die

undersized

People

Extrusion

rate

too high

Materials

Material

too soft

Exercise

In your group, select a problem:

At Muhlenberg

Another organization

Develop a cause and effect diagram to address the problem

Deliverable: Develop the diagram and share solution with

class

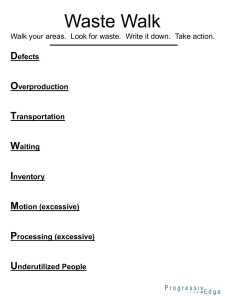

The System of Lean Production (Toyota, Citroen, …)

Principles

Zero Inventories

Zero Defects

Flexibility / Zero set-ups

Zero breakdowns

Zero handling / non

value added

Organization

Autonomation

Competence and Training

Continuous Improvement

Quality at the source

Methods

Just-in-time Production

• Kanban

• Classical Push

• “Real” Just-in-time

Mixed Production

Set-up reduction

Principles of Lean Production:

Zero Inventory and Zero Defects

Inventory in process

Buffer argument:

“Increase inventory”

• Avoid unnecessary inventory

• To be seen more as an ideal

• Two types of (bad) inventory:

a. resulting from defects / rework

b. absence of a smooth process flow

• Remember the other costs of inventory (capital, flow time)

Pictures: Citroen

Toyota argument:

“Decrease inventory”

Principles of Lean Production:

Zero Set-ups, Zero NVA and Zero Breakdowns

Avoid Non-value-added activities,

specifically rework and set-ups

• Flexible machines with short set-ups

• Allows production in small lots

• Real time with demand

• Large variety

• Maximize uptime

• Without inventory, any breakdown

will put production to an end

• preventive maintenance

Methods of Lean Production: Just-in-time

Push: make to forecast

•

•

•

•

Classical MRP way

Based on forecasts

Push, not pull

Still applicable for

low cost parts

Pull: Synchronized production

• Part produced for specific

order (at supplier)

• shipped right to assembly

• real-time synchronization

• for large parts (seat)

• inspected at source

Pull: Kanban

• Visual way to implement a pull system

• Amount of WIP is determined by

number of cards

• Kanban = Sign board

• Work needs to be authorized by demand

Methods of Lean Production:

Mixed Production and Set-up reduction

Production with large batches

Cycle

Cycle

Inventory

Inventory

Beginning of

Month

End of

Month

Production with small batches

Produce Sedan

Produce Station wagon

Beginning of

Month

End of

Month

Organization of Lean Production:

Autonomation and Training

• Automation with a human touch

• Create local decision making rather

than pure focus on execution

• Use machines / tools, but avoid the

lights-off factory

• Cross training of workers

• Develop problem solving skills

Organization of Lean Production:

Continuous Improvement and Quality-at-thesource

• Solve the problems where they occur

- this is where the knowledge is

- this is the cheapest place

Defect found

End User

Own Process Next Process End of Line Final

Inspection

$

$

$

$

$

• very minor • minor

delay

• Rework

• Significant

• Reschedule

Rework

• Delayed

Defect fixed

delivery

• Overhead

• Warranty

cost

• recalls

• reputation

• overhead

• Traditional: inspect and rework

at the end of the process

• Once problem is detected, send

alarm and potentially stop

the production

Costs of Quality

Appraisal Costs

External Failure

Costs

Costs of

Quality

Internal Failure

Costs

Prevention Costs