Thermooxidation and thermal degradation

advertisement

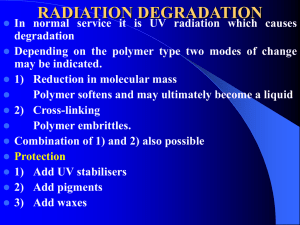

Thermo-oxidation and degradation of polymers Jozef Rychlý Polymer Institute Dúbravská cesta 9, 843 42 Bratislava, Slovak Republic Polyfriend workshop, september 5, 2013, morning Polymers utilised practically usually have unknown residual stability and the unknown concentration of additives – trajectory of the service life of the material Polyfriend workshop, september 5, 2013, morning Possible harmful effect on polymer products • Oxygen in air • Heat • Hydrolysis associated with humide atmosphere • Light of wavelength >300 nm • High energy radiation • Mechanical stress • Biological attack • Contacting liquids • Leaching of additives • Presence of different reagents Polyfriend workshop, september 5, 2013, morning Acid hydrolysis of cellulose chains – example of combination of cross reaction of hydrolysis and free radical oxidation on terminal groups formed subsequently from hydrolytic attack Polyfriend workshop, september 5, 2013, morning Chemical degradation is accompanied by the reduction of the molar mass, increase of the molar mass due to crosslinking, or it occurs as polymer analogous reaction typical by unzipping of side groups of the macromolecular chain. Degradation (physical) may involve also the physical processes like recrystallisation, denaturation (proteins). Ageing, (corrosion) is related to the long term degradation due to weathering and involves both. Polyfriend workshop, september 5, 2013, morning Chemical degradation Polymers are organic and inorganic materials composed of structural units – mers – kept together by chemical bonds. Their stability properties are detemined by long entangled chains and by free volume. Small change such as disruption of the chain may change the properties significantly. Polyfriend workshop, september 5, 2013, morning Physical degradation Loss of properties due the change in position of macromolecular chains and additives in the volume without necessary chemical change. Polyfriend workshop, september 5, 2013, morning Foil from low density polyethylene in advanced stage of its degradation Polyfriend workshop, september 5, 2013, morning Dissociation energies of bonds A-B in kJ/mol that may form the skeleton of the macromolecular structure in polymers. A\B C N O S Si C 348 292 352 259 290 N 292 160 222 O 352 222 139 S 259 Si 290 C=C 615 369 213 369 N=N 418 C=N 615 Polyfriend workshop, september 5, 2013, morning Degradation starts by the formation of active sites (radicals, ions, excited states) on the macromolecular chain. initiation + + Polyfriend workshop, september 5, 2013, morning Tests of oxidation stability Oxidation stability tests follow from Bolland Gee scheme: Time or temperature evolution of concentration of hydroperoxides, DSC, thermogravimetry, chemiluminiscence, analytical determination of carbonyls, mechanical properties changes, etc. Polyfriend workshop, september 5, 2013, morning Bolland-Gee scheme for free radical mechanism of polymer degradation valid to temperatures ca 250 oC, (P and Z denote macromolecular chains of the different length, InH is chain breaking inhibitor, D peroxide decomposer, P., Z. are polymer radicals Polyfriend workshop, september 5, 2013, morning Induction time, the easiest way of the characterisation of the polymer stability Polyfriend workshop, september 5, 2013, morning concentration of hydroperoxides, rel.u. more stabilized sample 1.0 0.8 unstabilized sample 0.6 less stabilized 0.4 sample 0.2 induction period 0.0 1000 10000 time, s Schématické znázornenie merania indukčnej periódy v stabilizovanom polypropyléne. Polyfriend workshop, september 5. 2013 100000 0.010 20000 0.008 0.006 0.004 0.002 0.000 0.008 0.010 [D]0, mol/l 16000 induction time, s 1 12000 8000 2 4000 0 0.000 0.002 0.004 0.006 [InH]0, mol/l Teoretická závislosť indukčnej periódy oxidácie určená pre wi=0, (nulová iniciačná rýchlosť podľa rov. 1, Schéma 1) od zloženia zmesi inhibítorov InH (“chain breaking” antioxidant) a D (rozkladač hydroperoxidov), u ktorej je suma koncentrácií 0.01 mol/l). Spodná krivka 2 zobrazuje závislosť indukčnej periódy pre tie isté hodnoty parametrov ako pre čiaru 1 ale wi=5 10-8 mol/l/. Počiatočná koncentrácia hydroperoxidov bola 0.001 mol/l Polyfriend workshop, september 5. 2013 Examples Polyfriend workshop, september 5, 2013, morning 1. Original and aged samples of polyether and polyester urethanes daylight (0-15 days), 1000 Wm-2, 25°C/50% RH Polyfriend workshop, september 5, 2013, morning Structural segments of polyurethanes CH3 CH3 CH3 O CH CH2 n O C NH NH C O CH2 CH O m O O Polyether urethane 1 CH3 O (CH2)6 O C CH2 CH2 2 CH2 C O (CH2)6 O C NH O O m NH C O O Polyester urethane 2 CH3 ( O CH CH2 ) CH3 n O C NH CH2 NH C O ( CH2 O O Polyether urethane 3 Polyfriend workshop, september 5, 2013, morning CH O ) m The comparison of non-isothermal thermogravimetry for reference sample polyether urethane 1 and polyester urethane 2 in nitrogen and oxygen, the rate of heating 5oC/min. Points denote the theoretical fit. 100 % of the mass 80 60 sample 2 nitrogen sample 1 oxygen 40 sample 2 oxygen sample 1 nitrogen 20 0 50 100 150 200 250 300 350 400 o temperature, C Polyfriend workshop, september 5, 2013, morning 450 500 550 Comparison of nonisothermal thermogravimetry and DSC records for polyether (sample 1) and polyester (sample 2) polyurethane foams, oxygen, the rate of heating 5 oC/min 12 100 1O 10 80 1O 6 2O 60 4 40 2 0 20 2O -2 100 200 300 o temperature, C Polyfriend workshop, september 5, 2013, morning 0 400 % of the mass DSC, mW 8 Chemiluminescence and DSC measurements in oxygen for non-aged samples 1 and 2. The rate of heating 5 oC/min. 300000 10 1 DSC, mW 8 1 200000 6 4 2 100000 0 2 -2 2 100 0 200 300 o temperature, C Polyfriend workshop, september 5, 2013, morning 400 chemiluminescence intensity, counts/s/1 mg 12 Obvious conclusion! Polyester urethane are hydrolytically less stable than polyether urethane while polyether urethanes are less stable towards light induced degradation. Polyfriend workshop, september 5, 2013, morning Characterisation of aged polyurethanes Polyfriend workshop, september 5, 2013, morning The chemiluminescence intensity runs for aged polyether and polyester urethanes samples 1a-3a (15 days-red), oxygen, 1-3 are original non-aged samples, the rate of heating 5 oC/min. Polyfriend workshop, september 5, 2013, morning The non-isothermal thermogravimetry runs for aged polyether and polyester urethanes samples 1a-2a (15 daysred), nitrogen, 1-2 are original non-aged samples, the rate of heating 5 oC/min Polyfriend workshop, september 5, 2013, morning Conclusion Degradation is inevitable symptom of the polymer service life. It can be slowed down, with much more pronounced induction time, but it cannot be avoided. The detailed knowledge on the kinetics is always necessary! Polyfriend workshop, september 5, 2013, morning