Degradation Profile of Electrospun PLGA Matrix Dana Dolev 1

advertisement

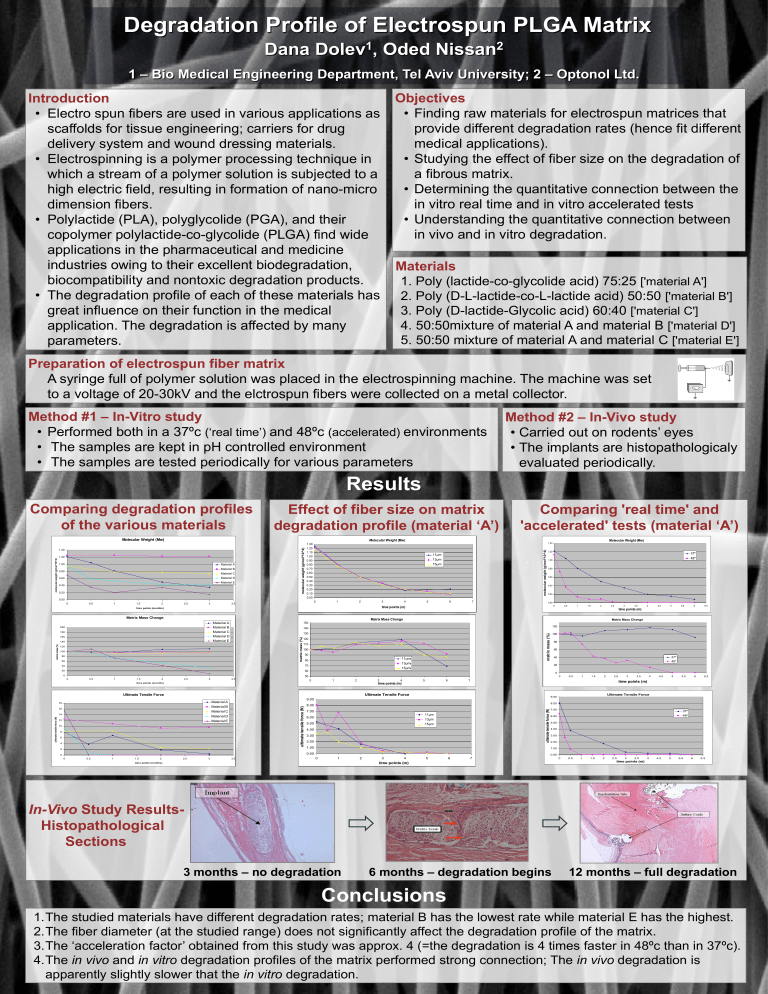

Degradation Profile of Electrospun PLGA Matrix 1 Dolev , Dana Oded 2 Nissan 1 – Bio Medical Engineering Department, Tel Aviv University; 2 – Optonol Ltd. Objectives • Finding raw materials for electrospun matrices that provide different degradation rates (hence fit different medical applications). • Studying the effect of fiber size on the degradation of a fibrous matrix. • Determining the quantitative connection between the in vitro real time and in vitro accelerated tests • Understanding the quantitative connection between in vivo and in vitro degradation. Introduction • Electro spun fibers are used in various applications as scaffolds for tissue engineering; carriers for drug delivery system and wound dressing materials. • Electrospinning is a polymer processing technique in which a stream of a polymer solution is subjected to a high electric field, resulting in formation of nano-micro dimension fibers. • Polylactide (PLA), polyglycolide (PGA), and their copolymer polylactide-co-glycolide (PLGA) find wide applications in the pharmaceutical and medicine industries owing to their excellent biodegradation, biocompatibility and nontoxic degradation products. • The degradation profile of each of these materials has great influence on their function in the medical application. The degradation is affected by many parameters. Materials 1. Poly (lactide-co-glycolide acid) 75:25 ['material A'] 2. Poly (D-L-lactide-co-L-lactide acid) 50:50 ['material B'] 3. Poly (D-lactide-Glycolic acid) 60:40 ['material C'] 4. 50:50mixture of material A and material B ['material D'] 5. 50:50 mixture of material A and material C ['material E'] Preparation of electrospun fiber matrix A syringe full of polymer solution was placed in the electrospinning machine. The machine was set to a voltage of 20-30kV and the elctrospun fibers were collected on a metal collector. Method #1 – In-Vitro study • Performed both in a 37ºc (‘real time’) and 48ºc (accelerated) environments • The samples are kept in pH controlled environment • The samples are tested periodically for various parameters Method #2 – In-Vivo study • Carried out on rodents’ eyes • The implants are histopathologicaly evaluated periodically. Results Comparing degradation profiles of the various materials Effect of fiber size on matrix degradation profile (material ‘A’) Molecular Weight (Mw) Material A Material B 0.80 Material C Material D 0.60 Material E 0.40 0.20 0.00 1 1.5 2 2.5 3 11µm 1.4 µm 13µm 3.5 µm 15µm 4.6 µm 0 3.5 1 2 3 150 200 Material B 140 180 Material C Material D 130 160 140 Material E 120 100 80 60 50 2.5 3 3.5 11µm 1.4 µm 13µm 3.5 µm 2 2.5 3 1 2 3 4 5 6 ultimate tensile force (N) Material C 14 Material D 12 Material E 10 8 6 4 2 2.5 3 3.5 5 5.5 6 6.5 5.5 6 6.5 60 37º 48º 40 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 time points (m) Ultimate Tensile Force 9.00 8.00 8.00 7.00 11µm 1.4 µm 6.00 13µm 3.5 µm 5.00 15µm 4.6 µm 4.00 3.00 2.00 1.00 7.00 37º 48º 6.00 5.00 4.00 3.00 2.00 1.00 0.00 0 4.5 80 7 9.00 Material B 4 100 0 0 Material A 3.5 20 Ultimate Tensile Force 16 ultimate tensile force (N) 1.5 time points (m) 18 2 1 0 Ultimate Tensile Force 1.5 0.5 15µm 4.6 µm tim e points (m onths) 1 0.00 120 80 60 0.5 0.20 Matrix Mass Change 90 0 0 0.40 time points (m) 100 20 2 0.60 0 110 70 1.5 7 120 40 1 6 0.80 Matrix Mass Change Material A matrix mass (%) matrix mass (%) Matrix Mass Change 0.5 5 37º 48º 1.00 time points (m) tim e points (m onths) 0 4 1.20 matrix mass (%) 0.5 molecular weight (g/mol*10^4) 1.00 Molecular Weight (Mw) 1.40 1.30 1.20 1.10 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10 0.00 ultimate tensile force (N) molecular weight (g/mol*10^4) 1.20 molecular weight (g/mol*10^4) Molecular Weight (Mw) 1.40 0 Comparing 'real time' and 'accelerated' tests (material ‘A’) 0.00 0 1 2 3 4 5 6 7 time points (m) tim e points (m onths) 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 time points (m) In-Vivo Study ResultsHistopathological Sections 3 months – no degradation 6 months – degradation begins 12 months – full degradation Conclusions 1.The studied materials have different degradation rates; material B has the lowest rate while material E has the highest. 2.The fiber diameter (at the studied range) does not significantly affect the degradation profile of the matrix. 3.The ‘acceleration factor’ obtained from this study was approx. 4 (=the degradation is 4 times faster in 48ºc than in 37ºc). 4.The in vivo and in vitro degradation profiles of the matrix performed strong connection; The in vivo degradation is apparently slightly slower that the in vitro degradation.