VERSAMID INK RESINS - Gabriel Performance Products

advertisement

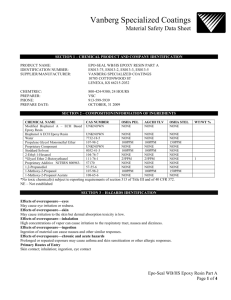

Gabriel Performance Products Cycloaliphatic Epoxy Resins GPE Series Product Technology, Curatives & Applications Cycloaliphatic Epoxy Resins (CER) Outline GPE Series Technology Features/Benefits - Value Products Activators/Hardeners Markets/Applications Cycloaliphatic Epoxy Resins (CER) Technology CER Technology CERs - Different from Standard Bisphenol-A Epoxy Resins like DER 331, EPON 828 Standard Epoxy resins made from Epichlorohydrin and Bisphenol-A CERs are made by oxidation of Cyclo Olefins with Peracetic Acid Different from other cycloaliphatic epoxy resins like Glycidyl Esters of Pthalic Acids (Huntsman CY 184) and Hydrogenated Bis A Epoxy Resins (CVC Epalloy 5000 and Hexion Epon 1110) Technology Standard Epoxy Resin : Epichlorohydrin + Bisphenol-A Std. Epoxy Resin Epichlorohydrin (DER 331, EPON 828) Bisphenol-A Technology Cycloaliphatic Epoxy Resin : Cyclo Olefin + Peracetic Acid GPE-221 GPE-221 Cyclo Olefin Peracetic Acid Cycloaliphatic Epoxy Resins (CER) Features/Benefits Value Proposition Feature/Benefits - Value Aliphatic Backbone – Excellent UV Stability Saturated Cyclic Ring – Good Weatherability and Excellent Electrical Properties High Epoxide Content High Crosslink Density High Tg and Heat Distortion Temp. (HDT) No Epichlorohydrin No Hydrolysable Chorine Low Dielectric Constant Excellent Arc-Track Resistance Feature/Benefits - Value Short Chain – Low Viscosity 350cp of GPE221 vs. 13000 cp Std Epoxy Resin Easy to handle and enable VOC Free or Low VOC Formulations When combined with Polyols, result in Good Combination of Toughness and Heat-Distortion Temperature Properties No Epichlorohydrin Low Potential for Skin Sensitization Offer latitude to formulate 1K or 2K Products Cycloaliphatic Epoxy Resins (CER) GPE Products GPE Series - Products GPE-221 : Standard, General Purpose Use Cycloaliphatic Epoxy Resin Equivalent to ERL-4221 (Cyracure UVR-6110) GPE-226 : Distilled, Low Ionic Content and Low Viscosity Cycloaliphatic Epoxy Resin Equivalent to ERL-4221D (Cyracure UVR-6105) GPE-228 : Flexible Cycloaliphatic Epoxy Resin Equivalent to ERL-4299 (Cyracure UVR-6128) ERL & UVR from Dow Chemical - Discontd. GPE Series - Properties Property\Product GPE-221 GPE-226 GPE-228 Appearance Colorless to Pale Yellow Liquid Colorless to Pale Yellow Liquid Colorless to Pale Yellow Liquid Color (Pt-Co) 100 max 50 max 150 max Viscosity, cP 350 - 450 200 - 350 500 - 650 EEW 131 - 143 128 - 140 190 - 210 Moisture (wt%) <0.05 <0.05 <0.05 Cycloaliphatic Epoxy Resins (CER) Activators/Hardeners Activators/Hardeners Anhydrides Polyacids UV Cationic Cure Catalysts Not ‘Amines’ or ‘Polyamides’ Activators/Hardeners Anhydrides 2K Thermal Cure OR Heat Cure Requires Heat to Cure HHPA (Hexa HydroPthalic Anhydide), MTHPA, NMA Typical Cure Cycle – 1 HR @ 100 -120 oC + 4 - 6 HR @ 160 -180 oC Cure Cycles vary with different Anhydrides Activators/Hardeners Anhydride Cured CERs Excellent High Temperature Performance Tg : 150 – 200oC High Mechanical Properties - Flexural Strength, Compressive Strength Excellent Dielectric Properties Superior Arc, Corona and Tracking Resistance Eg: Fiber Reinforced Composites Activators/Hardeners Polyacids 2K Ambient Cure Acid Functional Polyesters, Carboxylic Acids, Pthalic Acids Slow Reaction Rates Takes several days to cure Less Common in Use Activators/Hardeners UV Cationic Cure Catalysts Cationic Photoinitiators “Aryl Sulfonium” and “Aryl Iodonium” Salts Activated by UV Light Generate a Super Acid Super Acid catalyzes epoxy polymerization Rapid Cure Rates, in some cases Instant Activators/Hardeners UV Cationic Cure Catalysts Alternate technology to Free Radical Polymerization of Acrylates Low Shrinkage – up to 5%, compared to Acrylate Shrinkage of 10- 15% Excellent Adhesion Low Viscosity Low or No VOCs Low Capital and Operating Costs Excellent Hardness and Flexibility Cycloaliphatic Epoxy Resins (CER) Markets/Applications Value to the Market CERs have Excellent UV and Weatherability, Low Viscosity, High Temperature Performance, Excellent Electrical Properties and other…….But Complex Mfg Process High Product Costs $ 6 - 10/lb vs $1 – 2/lb of Standard Epoxy Resin Used in High Performance Requirement Markets/Applications Markets/Applications Fiber Reinforced Composites Low Viscosity – Good Fiber Wet-out Filament Winding, Pultrusion, Resin Transfer Molding (RTM) Tg in the range of 200oC – High Temperature Performance Eg: Aerial Booms, Antennas, Composites for Electrical and Electronic Applications 2 K A N H Y D R I D E C U R E Markets/Applications Electric Insulators Ceramic or Porcelain Replacements Bushings, Electric Insulators, Switch Gear Parts in transmission and distribution of electric power Excellent UV Resistance and Carbon Tracking Lighter Weight & Greater Impact Resistance Complex Shapes, Reduced Maintenance 2 K A N H Y D R I D E C U R E Markets/Applications Encapsulants & Potting Compounds Transformers, Electric Coils Low Dielectric Loss High Electrical Resistivity Low Viscosity – Good Penetration Excellent UV Resistance – LEDs and Optoelectronics Excellent Thermal Shock Resistance with Polyols 2 K A N H Y D R I D E C U R E Markets/Applications Coatings, Inks and Laminating Adhesives Rapid Cure Low Down Time Low or No VOC, No odor Excellent Adhesion to wide variety of substrates: steel, aluminum, polymer films Glossy, Hard and Good Flexibility Eg: Flexo Printing, Laminating Adhesives 1 K U V C U R E Markets/Applications Packaging – Overprint Varnishes Rigid Packaging - Steel & Aluminum Can Coatings (Beer & Beverages) Rapid Cure Rates Low or No VOC No Odor Glossy, Hard and Good Flexibility Retortable and Pasteurizable 1 K U V C U R E Markets/Applications Packaging – Overprint Varnishes Flexible Packaging: plastic tubes, films, paper Excellent Adhesion to wide variety of substrates Various Polymers: PET, PE, HDPE, PS, Polyester No Odor, Fast Drying Glossy, Hard and Good Flexibility 1 K U V C U R E Markets/Applications Acid Scavenger - Stabilizer CERs react with both organic and mineral acids Use to remove or stabilize Acids in Systems Eg: Transformer Fluids Lubricating Oils and Hydraulic Fluids 1 K A D D I T I V E Markets/Applications Acid Scavenger - Stabilizer Vinyl Inks and Coatings Dielectric Fluids in Electrostatic Capacitators Flame Retardant Coatings PVC and Polyester Resins 1 K A D D I T I V E Markets/Applications Other Uses: Modifier for Std Epoxy Resins, Viscosity Reduction, Performance Enhancement Waterborne – Stable Anionic Dispersions Chemical Intermediates – to make alkyd coating resins 1 K A D D I T I V E