MIT Rocket Team

advertisement

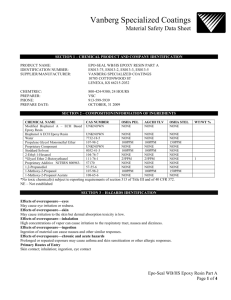

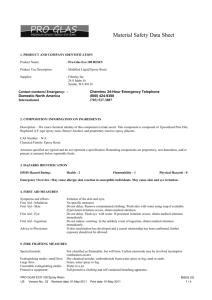

ROCKETS AND COMPOSITES Design and Fabrication MIT Rocket Team November 20, 2010 An Introduction to COMPOSITES Carbon Fiber Carbon fiber custom laminate Material: 5.7 oz 3k twill carbon fiber sheet Epoxy Aeropoxy 2032 resin Aeropoxy 3665 hardener Aspects High strength-to- weight ratio High cost Fiberglass Carbon fiber is RF opaque Material: 6 oz plain weave fiberglass Epoxy Aeropoxy 2032 resin Aeropoxy 3665 hardener Locations Fairing Potentially second stage body or sections General Fabrication Techniques Elevated temperature cure Custom-built oven Inner dimensions sufficient for full cure of either stage Capable of reaching in excess of 300º F Not necessary for epoxy choice, but provides additional temperature resistance Reduces cure time Improves resin distribution and mechanical properties Vacuum bagging Improves surface finish of part Reduces weight before removal of excess epoxy Body Tube Ply Layup Determine number of plies Meet loading requirements Manufacturing reasons Additional plies at bulkheads and ends Antisymmetic and Axisymmetric Your Mission Fin Design Sandwich laminate Balsa core (1/8”) Single–layer carbon fiber facesheets Construction Cut balsa to shape Cut vacuum bagging materials Apply thin film of epoxy to balsa Apply facesheets Apply additional epoxy and ensure is well distributed Apply vacuum bag release, then breather, then strechlon Insert vacuum tube and cover edges with sealant tape Fin Sizing Semispan: 5” Chord: 5”-3” [Build Composites] Basics to An Rocket Introduction ROCKETS Rocket Equation Initial Mass Propellant Structural Mass Fraction Payload Delta-V to Earth orbit: ~10 km/s Propulsion Type Isp Solid 250 LO2+LH2 450 LO2+RP-1 350 Electric 2000 Composites Design What are composites? Single Ply Carbon or glass fibers Epoxy matrix Usually unidirectional, but can be weave Laminate Multiple plies Sandwich Face sheets of plies Spacer material between Why Composites? Evaluation of Composites Standard Laminates Rule of Mixtures ETc = v f ETf + v m ETm Stiffness is simply the average of stiffnesses Be sure to account for direction Z Z Matrix Fiber T T L L graphite/epoxy Sandwich Materials Composites Fabrication Techniques (Cont) Body Tube Manufacturing Prepare mandrel of phenolic tube with wax, mylar Apply resin Apply fabric and work in resin Repeat for all plies Remove excess Apply vacuum bag material Bake for 1 hour Remove from mandrel Cut then sand edges Bulkhead Design Purpose: attach motor casings to airframe Design Options Plastic rings Holes included around periphery for wiring and antenna Inner portion secured with tape friction fit Outer portion secured with epoxy from both sides COTS casings Validation Static pull motor simulation Static fire testing Fairing Design Material: Fiberglass Design Options Tangent ogive: easy to build Von Karman: drag for large mach range Parabola: drag at subsonic speeds Construction Layup in halves on aluminum mandrel and plate Cure halves Affix together with strips Cure again Sand until smooth Apply additional filler as necessary Composites Fabrication Examples Fins Body Tube Nose Cone Completed SpaceX Interstage Mandrel Composite Testing Instron Testing Prep Load Testing Engine Testing Pyro Test On the Launch Rail Launch Merlin Engine Engine Fires Static Fires Questions?