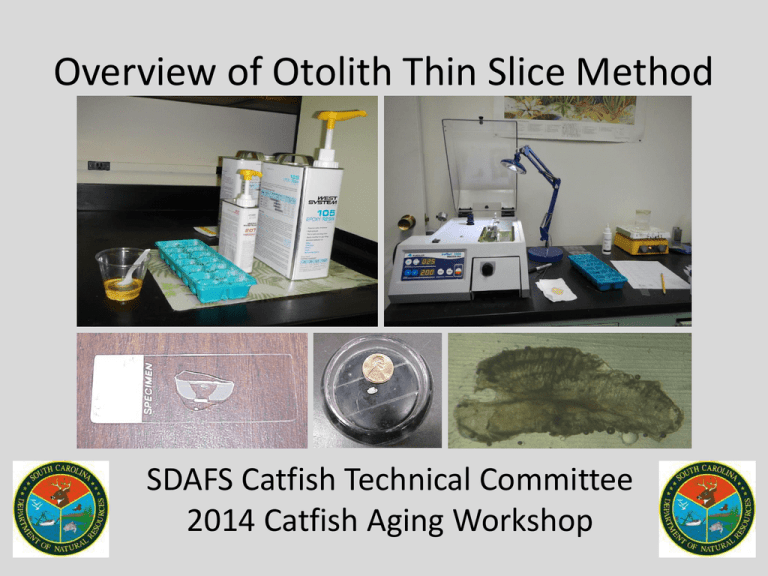

Overview of Otolith Thin Slice Method

advertisement

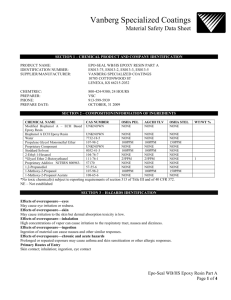

Overview of Otolith Thin Slice Method SDAFS Catfish Technical Committee 2014 Catfish Aging Workshop Procedures 1. Remove and dry 2. Set in epoxy resin 3. Thin slice using a slow speed precision saw 4. Mount thin slice to a slide using Cytoseal™ 5. View – using a fiber optic light and dissecting scope List of Items Used For Thin Slice Method -Slow speed precision saw (Isomet 1000) and cutting fluid (Isocut Plus Cutting Fluid) -Epoxy resin and hardener (West Systems 105 epoxy resin and 207 hardener) -Ice cube trays -Disposable plastic cup and spoon -Microscope slides -Cytoseal™ 60 -Forceps -Warm water -Paper towels 2. Set otolith in epoxy resin -Mix resin and hardener in a disposable cup -Pour base layer of epoxy and let harden (~4 hours) -Set otoliths in the tray -Cover with a second layer of epoxy resin and let harden (~typically overnight) 2. Set otolith in epoxy resin Set otoliths in resin with posterior edge near the edge of the epoxy resin Be Consistent! Set all otoliths with the same orientation to be able to make the same, consistent, cut on each otolith. 3. Thin slice w/slow speed precision saw 3. Thin slice w/slow speed precision saw Align the saw blade slightly to the right of the core of the otolith Zero the micrometer, set speed to 200 , lift chuck counter balance and push the blade button 3. Thin slice w/slow speed precision saw Cut off the posterior end of the otolith Raise the counter balance, spin the micrometer wheel until .025” appears on the digital readout 3. Thin slice w/slow speed precision saw 3. Thin slice w/slow speed precision saw Rinse thin slice in warm water and dry Repeat process to take a second cut 4. Mount thin slice to a slide using Cytoseal™ Apply a drop of Cytoseal™ to the slide, place thin slice on slide and cover with Cytoseal™ Remove air bubbles Allow to dry ~ 1 hour to view both sides of thin slice 5. View 5. View 5. View 5. View Same technique can be used for many species Flathead catfish Black crappie Striped bass Largemouth bass Grass Carp?? Questions