LABORATORY QUALITY

CONTROL

Course Code RIT 2.2 Revision C

Definitions:

• Quality Control:– the process of detecting errors

• Quality Assurance:– the systems or procedures in place to

avoid errors occurring

… to ensure the reliability of the test

results to give the best patient care !

Unreliable Performance ?

• Potential consequences include:– patient misdiagnosis

– delays in treatment

– increased costs

• avoidable retests cost US 200million USD per year

• Even a small calibration bias can effect

treatment rates:

– 1% +ve bias in cholesterol result

5% increase in patients exceeding the treatment cut-off

– 3% +ve bias

15% increase in patient treatment.

Error Classification..

• Pre-analytical:– errors before the sample reaches the laboratory

• Analytical:– errors during the analysis of the sample

• Post-analytical:– errors occurring after the analysis

Pre - Analytical Errors..

• Improper preparation of the patient:– patient fasting

• glucose test

– stress and anxiety

• urinary protein

Pre - Analytical Errors..

• Improper preparation of the patient

• Improper collection of the blood sample:– sample haemolysis

• LDH, potassium or inorganic phosphate

– insufficient sample volume

• unable to carry out all requested tests

– collection timing

• 24 hour urine

Pre - Analytical Errors..

• Improper preparation of the patient

• Improper collection of the blood sample

• Incorrect specimen container:– serum or plasma

– fluoride tubes for glucose

• to inhibit glycolysis

– EDTA unsuitable anti-coagulant for calcium

Pre - Analytical Errors..

•

•

•

•

Improper preparation of the patient

Improper collection of the blood sample

Incorrect specimen container

Incorrect specimen storage:– sample left overnight at room temperature

• falsely elevated K, Pi and red cell enzymes

– delay in sample delivery

• falsely lowered levels of unstable analytes

Other Factors..

• The sex of the patient

– male or female

• The age of the patient

– new born / juvenile / adult / geriatric

• Dietary effects

– low carbohydrate / fat

– high protein / fat

• When the sample was taken

– early morning urine collection pregnancy testing

• Patient posture

– urinary protein in bed-ridden patients

Other Factors..

• Effects of exercise

– creatine kinase / CRP

• Medical history

– heart disease / diabetes / existing medication

• Pregnancy

– hormonal effects

• Effects of drugs and alcohol

– liver enzymes / dehydration

Analytical Errors..

• The sample:

– labelling

• barcoding / aliquoting

– preparation

• centrifugation / aspiration

– storage temperature

• short –term refrigeration

• medium term freezing at –20oC

• long term freezing at -80oC

– correct test selection

• Laboratory Information Management System (LIMS)

Analytical Errors..

• The sample:

• Glassware / pipettes / balances:

–

–

–

–

used incorrectly

contaminated

poorly calibrated

reuse of pipette tips

Analytical Errors..

• The sample:

• Glassware / pipettes / balances:

• Reagents / calibrators / controls:

– poor quality

– inappropriate storage

• correct temperature

• badly maintained fridges or freezers

– stability

• shelf-life / working reagent

– incorrect preparation

Analytical Errors..

•

•

•

•

The sample:

Glassware / pipettes / balances:

Reagents / calibrators / controls:

The application:

– incorrect analytical procedures

– poorly optimised instrument settings

Analytical Errors..

•

•

•

•

•

The sample:

Glassware / pipettes / balances:

Reagents / calibrators / controls:

The application:

The instrument:

– operational limitations

• temperature control/read times/mixing/carry-over

– lack of maintenance

• worn tubing / optics / cuvettes / probes

Other Factors..

• Calculation errors:

– incorrect factor / wrong calibration values

• Transcription errors:

• Dilutions errors:

– incorrect dilution or dilution factor used

• Lack of training:

• The human factor:

– tiredness / carelessness / stress

Post - Analytical Errors..

• The prompt and correct delivery of the

correct report on the correct patient to

the correct Doctor.

• How the Clinician interprets the data to

the full benefit of the patient.

Accuracy ?

How correct

your result is.

Precision ?

The

reproducibility

of your results.

Accurate and Precise..

Imprecise but Accurate !

Precise but Inaccurate !

Specificity ?

• The ability of a method to measure solely

the component of interest.

• A lack of specificity will affect accuracy

– falsely elevated values

• hormones and drugs

– falsely low values

• BCP method with bovine albumin

Sensitivity ?

• The ability to detect small quantities

of a measured component.

– will affect both precision and accuracy at the

bottom end of the assay range.

Normal Distribution..

Frequency

Mean value (x)

Measured value

Values fall randomly about a mean value.

Precision ?

• How disperse the values are.

• Quantified by measuring the Standard

Deviation (SD) of the set of results.

Standard Deviation (SD)..

SD =

(

(xi - x)

2

)

n -1

The lower the SD the better the

Precision.

Example:

Mean result (x) = 100 mmol/L

Standard deviation (SD) = 1.0 mmol/L

Number of results (n) = 100

Mean +/- 1SD..

Frequency

-1SD

x

+1SD

68%

99 100 101

Values fall randomly about a mean value.

Mean +/- 2SD..

Frequency

-2SD

x

+2SD

95%

98

100

102

Values fall randomly about a mean value.

Which is more Precise ?

Potassium SD = 0.1 mmol/L

Sodium

SD = 2.0 mmol/L

Coefficient of Variation..

CV =

SD

x 100%

Mean (x)

A %CV takes into consideration the

magnitude of the overall result.

Example:

Potassium %CV = (0.1 / 5.0) x 100%

= 2.0%

Sodium %CV = (2.0 / 140) x 100%

= 1.4%

Sodium has the better CV and in this

example is performing better than

potassium.

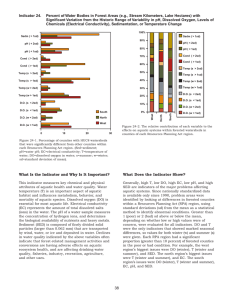

Interpretation..

10 40

41 50

51 70

71 100

101 120

unacceptable performance

need for improvement

acceptable

good

excellent

TS Calculations

V = (Result - Mean for Comparison) x 100

Mean for Comparison

The mean for comparison could be either:

– the all method mean

– your method mean

– your instrument mean

TS Calculations

TS = Log10 (3.16 x TCV)

x 100

V

TCV is Target Coefficient of Variation

TS Calculations

TS = Log10 (3.16 x TCV)

x 100

V

3.16 is selected as a constant because:

– the log10 of 3.16 is 0.5

– so if V = TCV, then the target score will be 50

TS =

log10 3.16 x TCV x 100

V

=

log10 3.16 x 3.7

3.7

=

log10 (3.16) x 100

=

50

x 100

How can Analytical

Quality be

Controlled ?

• Internal Quality Control (IQC).

– daily monitoring of quality control sera

• External Quality Assessment (EQA).

– comparing of performance to other laboratories.

Internal Quality Control..

• Daily monitoring

– precision

– accuracy

• Quality control sera

– results within control limits indicates

that analytical system is running

satisfactorily

What is Acceptable ?

A sodium control has a target value

of 140 mmol/L

139 mmol/L

120 mmol/L

140 mmol/L

160 mmol/L

141 mmol/L

180 mmol/L

What is Acceptable ?

• A range of acceptable values is established

• Sodium Control:- 137 143mmol/L.

What are the Options ?

• Unassayed serum:

– the cheaper option !

• but the laboratory must establish its own ranges

– cannot be used to assess accuracy !

• no externally assigned target values

• Assayed serum:

– with predetermined targets and ranges

• established by the manufacturer.

Unassayed Serum..

• Analysed extensively by the laboratory.

– a minimum of 20 sets of data generated

– a mean +/- 2SD range established

• 95% of results acceptable

– some laboratories may adopt tighter ranges

Assayed Serum..

• Targets and ranges generated by the

manufacturer:

– abc utilises RIQAS

• database of 5,000 laboratories

• method / instrument / temperature specific values

Levey Jennings Chart

+2SD

143

+1SD

141.5

X

X

X

X

Mean

X

X

X

X

140

X

X

X

X

X

X

-1SD

X

-2SD

X

X

138.5

137

Levey Jennings Chart

+2SD

143

+1SD

141.5

X

Mean

X

X

X

X

X

X

X

-1SD

-2SD

X

X

X

X

X

X

140

X

X

X

138.5

137

Levey Jennings Chart

+2SD

143

+1SD

X

X

X

X

Mean

X

X

X

X

-1SD

-2SD

X

X

X

X

X

141.5

X

X

140

X

X

138.5

137

Levey Jennings Chart

+2SD

143

+1SD

X

X

X

X

X

Mean

X

X

X

X

X

X

X

X

X

X

141.5

X

X

140

-1SD

138.5

-2SD

137

Levey Jennings Chart

+2SD

143

X

X

X

X

+1SD

141.5

X

X

X

Mean

140

X

X

-1SD

-2SD

X

X

138.5

X

X

X

X

X

X

137

Levey Jennings Chart

+2SD

143

X

X

X

+1SD

141.5

X

X

X

Mean

X

X

X

X

X

X

140

X

-1SD

X

-2SD

X

X

X

138.5

137

Levey Jennings Chart

+2SD

143

+1SD

X

X

X

X

141.5

X

X

X

X

X

Mean

140

X

X

-1SD

-2SD

X

X

X

X

X

X

138.5

137

Westgard Rules..

• Decision criteria is dependent on the

precision of the method or analyser

– the less precise the method the more

difficult the decision.

• Westgard provides multiple QC rules:– defines acceptability

• minimises false rejections

• maintains high error detection

Westgard Flowchart..

Control data

No

1 point

In control – report data

outside 2 SD

Yes

1 point

outside 3 SD

No

No

2 consecutive

No

Difference between

4 consecutive control

No

values outside

2 controls within

the same 2 SD

a run

of the mean and

exceeds 4 SD

further than

values on one side

1 SD from the mean

Yes

10 consecutive

No

values

on one side of

the mean

Yes

Yes

Yes

Out of control – reject analytical run

Yes

External Quality

Assessment..

.. the main objective of EQA is not to

bring about day to day consistency

but to establish inter-laboratory

comparability

EQA Options..

• International / National / Regional

• International schemes provide:– a larger database of results

– a wider range of analytical methods

– a global representation of diagnostic

manufacturers

• Compulsory or Voluntary

A Typical EQA Scheme..

• Participants receive unknown samples.

– these are analysed ‘blind’

– the results returned to scheme

organiser

– they are statistically analysed

– to generate a comparative report

– report sent to participant

RIQAS

•

abc

International Quality Assessment Scheme

– launched in 1988

– 5000 participants

• Management tool

– to assess, review and improve performance

RIQAS..

• Annual subscription

– two six monthly cycles

• Weekly samples

– one vial reconstituted per week

– tested blind as if a patient sample

• Results reported back to abc

– statistically analysed

• Weekly Report generated