6. Organic Solvents

advertisement

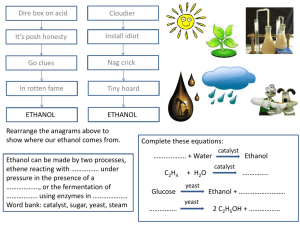

ORGANIC SOLVENTS Ethanol, acetone, butanol, glycerol Petrochemical industries Due to scarcity of oil and natural gas alternatives for commercial production Use of low cost raw materials (wood, cellulose, starch) ALCOHOL Chemically manufactured by hydration of ethylene (C2H4) In developing countries microbial fermentation is preferred to cheap raw material available. Now other countries also realize the potential due to political and economic analysis. AS A MOTOR FUEL Green petrol produced using sugar based plants like sugarcane and cassava. The pioneers are Brazil, with several fermentation and distillation plants the 90% of new cars are run on alcohol as a fuel. BioAlcohol from Plant Biomass •Fermentation produces alcohol •Raw materials are 1. STARCHy materials (wheat, rice, maize and potato) 2. CELLULOSic material (wood, agricultural wastes) Brazil: first country to produce ethanol by large scale yeast fermentation by using sugarcane and cassava Advantages of ethanol as motor fuel: less envtal. Pollution, 60%less CO2 as compared to petrol, 65% less Hydrocarbon and 15% less nitric oxide Flash point (temp. at which substance ignites) is higher (45oC) than petrol (13oC) Disadvantages Costlier than petrol Starting engines in cold difficult Ethanol may react with Al and Mg to damage containers Should not pick H2O from air (i.e. highly pure) can cause corrosion of engines and tanks and will not burn Gasohol: 20% ethanol (has to be highly pure) and 80% petrol (used in USA) Ethanol by Fermentation of Micro-organisms Yeasts: Saccharomyces cerevisae Bacteria: Zymomonas mobilis Raw material: Sugary material (molasses, whey, glucose, sucrose) Starchy materials (wheat, rice, maize, potato, cassava) Cellulosic material (wood, agricultural wastes) Pretreatment of raw material: Depends on type of raw material. Sugary materials : mild Cellulosic: extensive acidic or enzyme hydrolysis to release monosaccharide units PRE TREATMENT: Hydrolysis, clarification, filtration RAW MATERIAL PRE TEATMENT Milled grain steam Gelatinized material cool a-amylase Bacillus amyloliquefaciens Liquefied material Glucoamylase Saccharified material Glucose isomerase Fructose FERMENTATION Yeast Fermentation Alcohol Industrial production of alcohol and fructose from starch ETHANOL FERMENTATION RAW MATERIAL PRETREATMENT STERLIZATION Molasses pH 4-4.5 21-26oC---30oC O2 initially Anaerobic conditions after CO2 produced STARCH Hydrolysis GLUCOSE Glycolysis PYRUVATE pyruvate decarboxylase, TPP, Mg, CO2 ACETALDEHYDE Alcohol dehydrogenase, NADH+H+ ETHANOL FERMENTATION SEPARATION DISTILLATION DEHYDRATION STILLAGE (wastes concentration) Ethanol at high conc inhibits its own synthesis Eg. Yeasts at 5% alcohol, growth ceases Zymomonas mobilis tolerate 13% 1g glu to 0.511g ethanol (theory) Pure substrates (glu, lac, suc): 95% conversion rate Corn starch (industrial grade): 90% 100g pure glucose: 48.5g of ethanol produced, 46.5g CO2, 3.3g glycerol and 1.3g biomass USED FOR FUEL, FEED OR FERTILIZER, SCP, METHANOL Biofuel Biofuel is defined as solid, liquid or gas fuel derived from recently dead biological material and is distinguished from fossil fuels, which are derived from long dead biological material. Theoretically, biofuels can be produced from any (biological) carbon source Two common strategies of producing biofuels One is to grow crops high in sugar (sugar cane, sugar beet, and sweet sorghum) or starch (corn/maize), and then use yeast fermentation to produce ethyl alcohol (ethanol). The second is to grow plants that contain high amounts of vegetable oil, such as oil palm, soybean, algae, or jatropha. When these oils are heated, their viscosity is reduced, and they can be burned directly in a diesel engine, or they can be chemically processed to produce fuels such as biodiesel. Wood and its byproducts can also be converted into biofuels such as woodgas, methanol or ethanol fuel. It is also possible to make cellulosic ethanol from non-edible plant parts, but this can be difficult to accomplish economically. Agricultural products specifically grown for biofuel Corn, switchgrass, and soybeans, primarily in the United States; rapeseed, wheat and sugar beet primarily in Europe; sugar cane in Brazil; palm oil and miscanthus in South-East Asia; sorghum and cassava in China; jatropha in India. Hemp has also been proven to work as a biofuel. Biodegradable outputs from industry, agriculture, forestry and households can be used for biofuel production, either using anaerobic digestion to produce biogas, or using second generation biofuels; examples include straw, timber, manure, rice husks, sewage, and food waste. Biomass can come from waste plant material. The use of biomass fuels can therefore contribute to waste management as well as fuel security and help to prevent climate change, though alone they are not a comprehensive solution to these problems. Bioethanol Can be used as a replacement to petrol for automobiles 1930s in USA ethanol was produced from maize at 20% conc to produce gasohol called AGROL In UK gasoholwas markted by Cleaveland Oil Company undr name DISCOL till 1960s until petrol became available and cheaper. Large scale production was started in 1975 in Brazil follwed by USA in 1978 Ethanol producing microorganisms Glucose Yeast Saccharomyces cerevisiae Glycolysis S. carlsbergensis Kluyeromyces fragilis TCA cycle CO2 Bacteria Candida tropicalis Zymomonas mobilis Clostridium thermocellum Pyruvate Acetaldehyde NADH NAD+ Ethanol Vegetable oil Plant with sugar (sugarcane) Plant with starch (maize, potato, cassava) Plant with lignocellulose treatment Esterification PURIFIED OIL BIODIESEL Hydrolysis Gasification Dehydration Synthetic catalysis BIOETHANOL BIOMETHANOL Bioethanol from LignoCellulosic waste Clostridium acetobutylicum C. butyricum ACETONE AND BUTANOL Acetone used in manufacture of nitrocellulose for explosives wood hydrolysates, molasses, starch, sucrose Glucose Acetyl COA Pyruvate Acetyl CoA Acetyl PO4 Acetic acid Acetoacetyl CoA Acetyl COA b-hydroxybutyl CoA Crotonyl CoA Butyryl CoA Butyric Acid b-hydroxyb-methyl glutaryl CoA Acetyl COA Acetoacetic acid Acetone Isopropanol Butanol Nowadays acetone and butanol are by products of petroleum industry Fermentation is discontinued PRODUCTION Raw material: molasses, ammonium sulphate, Ca CO3, corn steep liquor, gassed with CO2, starting pH 5.8-6.0, 34oC, 36h Phase I: rapid growth, acetic acid, butyric acid, titratable acidity, pH5.2 Phase II: incr in acetone, butanol decr in acidity (acid break) Phase III: decr in solvent production and no incr in pH Contamination: absolute sterile conditions are required, bacteriophages and Lactobacilli cn be contaminants Product yield: 30% carbohyd. Gets converted. With molasses 7:3 butane acetone and corn medium 6:3. Production of butanol is influened by its toxicity…more than 13.5% conc is toxic. Recovery: acetone and butanol recovered by continuous distillation and fractionation. Leftover residue is used as animal feed after drying. GLYCEROL • Starting material for manufacture of explosives • Produced by saponification of fats and oils. • Chemically synthesized from propylene or propane Produced by yeast during alcoholic fermentation Sodium bisulfite blocks blocks alcohol production and large scale glycerol production PRODUCTION 2-3 days 50% yield Glucose Fructose 1,6 bisPO4 Glyald 3 PO4 Pyruvate Acetaldehyde ACETALD. SULFITE COMPLEX Sodium bisulfite blocks Ethanol Sodium sulfite +CO2 ---> Sod bisulfite DHAPO4 DHAP dehydrogenase Glyald 3 PO4 CH2-OH GLYCEROL CH-OH CH2-OH PRODUCTION from alga and bacteria Dunalielia salina in Israel, lives in high salt envt and synthesizes glycerol to balance osmotic pressure of hypersaline lakes. When surrounding salt is more more intracellular solutes (glycerol) When surrounding salt conc is reduced, glycerol is exxcreted out into medium Bacillus subtilis capable of converting glucose to glycerol, ethanol, Lactic acid, butanediol Produces high yield at anaerobic conditions despite being an aerobic MO