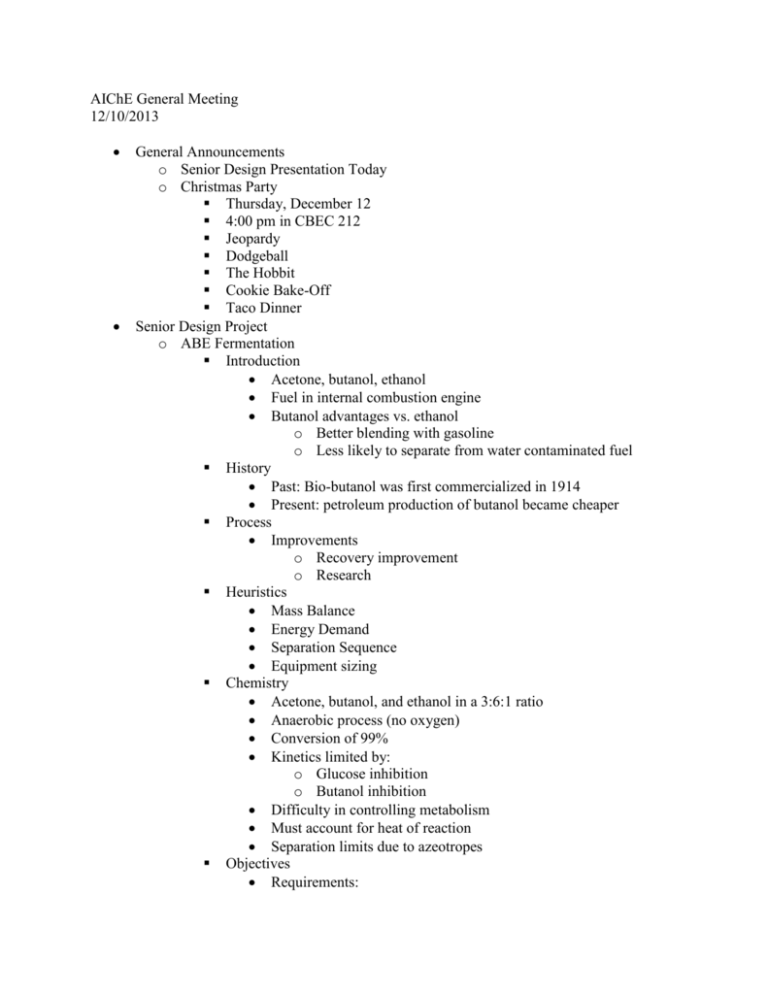

December 10th, 2013

advertisement

AIChE General Meeting 12/10/2013 General Announcements o Senior Design Presentation Today o Christmas Party Thursday, December 12 4:00 pm in CBEC 212 Jeopardy Dodgeball The Hobbit Cookie Bake-Off Taco Dinner Senior Design Project o ABE Fermentation Introduction Acetone, butanol, ethanol Fuel in internal combustion engine Butanol advantages vs. ethanol o Better blending with gasoline o Less likely to separate from water contaminated fuel History Past: Bio-butanol was first commercialized in 1914 Present: petroleum production of butanol became cheaper Process Improvements o Recovery improvement o Research Heuristics Mass Balance Energy Demand Separation Sequence Equipment sizing Chemistry Acetone, butanol, and ethanol in a 3:6:1 ratio Anaerobic process (no oxygen) Conversion of 99% Kinetics limited by: o Glucose inhibition o Butanol inhibition Difficulty in controlling metabolism Must account for heat of reaction Separation limits due to azeotropes Objectives Requirements: o 99.5% butanol and ethanol o At least 90% aceton purity PFD Fermenter to flash to 3 distillation columns Process Description Purchase corn Grind corn Mix with water Cooked to fertilize Sent to fermenter o ABE produced Separated o Non dissolved solids: centrifuge o “Syrup” goes to evaporators Fermenter Batch vs. Continuous o Batch: easy to model, limited upset loss, easy to clean o Continuous: faster rates In Situ Gas Stripping o Strip ABE from the fermenter while it’s running o Removes product as its formed o Requires extremely high gas flow rates Product Recovery o Partial condenser to remove non-condensables o Remove excess water o Extra stages allow for increased purity, which saves money o Series of decants allows for separation of butanol-water o Adsorber columns to separate ethanol and water Heat Generation o Equation to determine the eat being generated o Total rate: 3.27*10^9 kJ/hr o Result verification conducted Safety Low to moderate temperatures Atmospheric pressure Fire hazard o Volatile organics o Hydrogen gas Safety valves o Over the fermenter o On the distillation columns overheads Economic Analysis Become profitable after year 4 Major costs come from towers and solids handling Operating costs mainly from heat exchanger To reduce costs: less water Conclusions Separating out water reduces costs Azeotropes cause significant difficulty Safe design at low temperatures and pressures In-situ stripping not feasible Recommendations Alternative separations Different substrates Different types of bacteria Questions What’s an azeotrope? o 2 components form a different boiling point than the separate components Biggest challenge? o Separating butanol and water o Gas stripping o Working with Aspen and azeotropes o Determining heat inside of the fermenter Why only 90 g/L of substrate? o Any higher and reached the value where the microorganisms were destroyed How long is the cycle on the molecular sieves? o Analyzer in the outlet stream Why heating so much water? o Condenser o Keep ABE out of the water Water utilization target? o 2.5 gallons water for every 1 gallon butanol produced Operating Costs for how many years? o One year: lots of low pressured steam Products in fermenter vapor stream? o Everything came off but didn’t add another adsorber column because of additional water Burn off acetone. What to do with ethanol? o Sell both ethanol and butanol