06_Part_03_Dipsplay And Photosensing Systems

advertisement

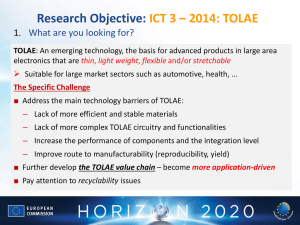

DISPLAY SYSTEMS AND PHOTOSENSORS (PART 3) LCD TFT LED-OLED CCD CMOS Introduction to: OLED and PLED Mehdi.SHarif Organic light-emitting diodes (OLEDs) have made great progress since the first presentation of thin film devices based on small molecule organic materials by Tang and VanSlyke in 1987. The OLED performance and stability have been rapidly increased over the last years. Also, the size of the devices is growing and several applications like displays and general lighting are produced. The developments for lighting applications will reach high efficiencies and low cost production to replace fluorescent and phosphorescent lamps. Because of very thin active layers (several 10–100 nm), the low material amount used for the production of OLED results in cheap and lightweight products • An organic light emitting diode (OLED) is a light emitting diode • In OLED the emissive electroluminescent layer is a film of organic compounds . • There are two main families of OLEDs: those based upon small molecules and those employing polymers. • Adding mobile ions to an OLED creates a Light-emitting Electrochemical Cell or LEC, which has a slightly different mode of operation. • An OLED display functions without a backlight. Thus, it can display deep black levels and can be thinner and lighter than liquid crystal display (LCD). • Bottom or top emission: • Transparent OLEDs: it much easier to view displays in bright sunlight • Inverted OLED: STACKED OLEDS : Molecules commonly used in OLEDs include organometallic chelates chelate Alq3 Tris(8-hydroxyquinolinato)aluminium Perylene Alq3 has been used as a green emitter, electron transport material and as a host for yellow and red emitting dyes. Polymer light-emitting diodes (PLED), also light-emitting polymers (LEP), involve an electroluminescent conductive polymer that emits light when connected to an external voltage. derivatives of poly(p-phenylene vinylene) and polyfluorene poly(p-phenylene vinylene) The first blue light emitting polymer diode was produced with a substituted polyfluorene polyfluorene vapor thermal evaporation (VTE) Color patterning • Vacuum deposition is not a suitable method for forming thin films of polymers. • Polymers can be processed in solution, and spin coating is a common method of depositing thin polymer films. • The metal cathode may still need to be deposited by thermal evaporation in vacuum. Lower cost in the future: Light weight & flexible plastic substrates: Wider viewing angles & improved brightness: Better power efficiency: LCDs filter the light emitted Response time Disadvantages Lifespan: The biggest technical problem for OLEDs was the limited lifetime of the organic materials a lifetime of around 14,000 Color balance issues Water damage UV sensitivity MANUFACTURERS AND COMMERCIAL USES • Samsung applications • Sony applications • LG applications 15 inch 15EL9500 REFERENCES: • http://en.wikipedia.org/wiki/Organic_light-emitting_diode • http://en.wikipedia.org/wiki/Chelation • http://electronics.howstuffworks.com/oled1.htm • http://www.jbibbs.com/hdtutorial/futuretech.htm • http://www.oled-display.net • Sung-Jin Kim ,Yadong Zhang,Organic Electronics 12 (2011) 492–496 • M. Eritt , C. May a, K. Leo et al Thin Solid Films 518 (2010) 3042–3045