3D Meetup Presentation

advertisement

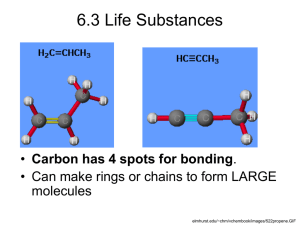

Material Science of 3D Printing Filaments Milwaukee 3D Meet Up Coex3D 11-2-2013 Topics • Filament Manufacturing • Upstream • Extrusion • Down Stream • Polymer Science 101 • Monomers • Morphology • Melt Behavior • Filaments • Discussion Filament Manufacturing Filament Manufacturing Up-Stream Processing Resin Drying • Critical steps in resin processing • Hydrophilic resins needs to be dried to make 3D filament • PLA, PET, PC, PA, PVOH are highly Hydrophilic • ABS slightly Hydrophilic Filament Manufacturing Up-Stream Processing Resin Drying Filament Manufacturing Up-Stream Processing • Color Feeders • Color concentrates • Additives • Throat Mixers • Magnet Filament Manufacturing Real Extruders Extruder Elements • Zone Heated Barrel • Screw • Screen Pack • Breaker Plate Filament Manufacturing Real Extruders Process Conditions on Extruders • Melt Temperature • Melt Pressure • RPMs • Motor Load Filament Manufacturing Real Extruders Extruder Screws • Feeding • Melting • Compression • Mixing • Material Specific Filament Manufacturing Water Quench Water Bath • Filaments are often water quenched • Molten phase to solid phase • Methods are often trade secret • 10-30 feet water cooling Filament Manufacturing Filament Orientation Filament Manufacturing Laser Micrometer Filament Manufacturing Spooling Filament Manufacturing Packaging Polymer Science for 3D Printers Polymer Science 101 for 3D Printers Plastic vs. Polymer Plastic • Plastics are polymers which, under appropriate conditions of temperature and pressure, can be molded or shaped. Polymer • A large molecule formed by the chemical union of five or more identical combining units called monomers Polymers Science 101 Monomers • Number of monomers (Molecular Weight) influences viscosity and strength properties • (wax 30-350 RU, PP 7,000 – 24,000 RU) • Types and location of the monomer influence polymer chemical and mechanical properties Polymers Science 101 Morphology Polymers Science 101 Melt Behavior - Viscosity • Viscosity • Melt Index Test (MI or MFR) • Mass/Time @ Temp & Weight • 3D Printing Filaments are typically injection molding resin grades • 10+g/10 min @ 220°C 10kg • Lower MI or MFR would require more force on filament advance • Intrinsic viscosity (IV) is used to measure viscosity for polymers like PET Polymers Science 101 Melt Behavior – Melting Temps • Thermal Transitions • Glass Transition – Amorphous materials flow, they do not melt • Melting Point – The temp at which a crystalline structure transitions to a liquid Amorphous structure 3D Printing Filaments Polymer Science 101 Polylactide (PLA) - General Polylactide (PLA) • Biopolymer - derived from corn • Relatively clean resin • Condensation reaction • Translucent • Translucent Blue Polymer Science 101 Polylactide Polylactide (PLA) • Morphology • • • • Semi-crystalline polymers Filament production method and colorants will change crystalinity levels Resin has a Tg 55-60°C & Tm of 145-160°C Different processing temps on printer (≈220°C) • Melt Behavior • MFR: 6 g/10 min (210°C & 2.16 Kg) • Monomer • Latic Acid • Density: 1.24 g/cc Polymer Science 101 ABS Acrylonitrile Butadiene Styrene • Derived from 3 monomers • Monomers % - Properties • Not a clean resin to extrude • Opaque Polymer Science 101 ABS Acrylonitrile Butadiene Styrene (ABS) • Morphology • Amorphous • Grade dependent Tg 100°C - 130°C • Melt Behavior • MFR: 1.1 g/10 min (200° C & 5 Kg) • MFR: 13 g/10 min (220° C & 10 Kg) • Monomer • Acrylonitrile, Styrene & Butadiene • Density: 1.03 g/cc Polymer Science 101 PVOH PVOH • Water soluble polymer • Commonly used in 3D Printing for structural elements that are dissolved after print is complete • Narrow gap between PVOH melting temp and thermal degradation – run as cool as possible • Keep Dry when not in use Polymer Science 101 CX-Glass & CoPET • CX-Glass (Developmental) • Glass like polymer • Extremely clean polymer • Morphology • Amorphous • Melt Behavior • MFR: 13 g/10 min (220° C & 10 Kg) • Clear • Heated bed required CoPET (Developmental) • Copolyester polymer • Clean polymer • Morphology • Amorphous • Melt Behavior • MFR: 10 g/10 min (220° C & 10 Kg) • Clear Polymer Science 101 CX-Glass & CoPET General Polymer Properties General Filament Properties Typical Printing Range MFR Polymer Morphology Monomer Density ABS ABS - HT Amorphous Amorphous 15-30% AN, 5-30%B 40-60% S 15-30% AN, 5-30%B 40-60% S (g/cc) 1.03 1.06 PLA Semi-Crystalline Lactic Acid 1.24 PVOH Amorphous Vinyl Alcohol 1.28 CoPET CX-Glass Amorphous Amorphous NA NA 1.27 1.02 190C @ 21.6 Kg 210C @ 220 C @ 230 C @ 2.16 Kg 10 Kg 2.16 Kg (g/10 min) 13 6 Tglass VSP Tmelting (°C) (°C) 217 257 (°C) 6 145-160 27 10 11 Comments (°C) 210-240 250-265 Slightly Hydrophillic Slightly Hydrophillic 210-230 Higly Hydrophillic 85 120 160-180 Higly Hydrophillic, Run Cool 80 78 85 240-265 220-240 Higly Hydrophillic NA Thank You If you would like a copy of the presentation just drop me an email at Sales@CoexLLC.com Or coex3d.com/contact