Thermal-Conversion Technologies of Biomass(2)

advertisement

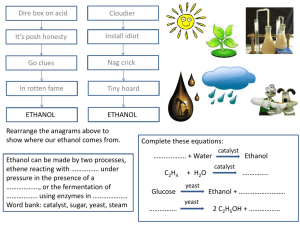

BIOMASS CONVERSION TO BIO-FUELS ChE 481 Lecture 2 LECTURER: MANUEL GARCIA-PEREZ , Ph.D. Department of Biological Systems Engineering 205 L.J. Smith Hall, Phone number: 509-335-7758 e-mail: mgarcia-perez@wsu.edu LECTURE OUTLINE A.- INTRODUCTION TO ETHANOL PRODUCTION B.- ETHANOL FROM SUGARCANE C.- CELLULOSIC ETHANOL A.- INTRODUCCION TO ETHANOL PRODUCTION Growth of the ethanol manufacturing capacity: Driven by blending mandates, subsidies and tax incentives enacted at the government level. http://www.marketresearchanalyst.com/2008/01/26/world-ethanol-production-forecast-2008-2012/ A.- INTRODUCCION TO ETHANOL PRODUCTION World Ethanol Production 60 % derived from sugar Crops 30 % derived from grains (mostly corn) 7 % derived from ethylene (synthetic ethanol) 3 % bio-conversion of other feedstocks Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 B.- ETHANOL FROM SUGARCANE Sugar Cane Yield http://en.wikipedia.org/wiki/File:SugarcaneYield.png A.- INTRODUCCION TO ETHANOL PRODUCTION Although the basic process of ethanol production from sugar cane has not changed greatly for several decades, significant improvements were made throughout the 1980s and 1990s. Mackay, Australia Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 B.- ETHANOL FROM SUGARCANE Production of Ethanol in Brazil Total cost of ethanol from sugarcane: $ 0.81/gal Total Cultivated Land devoted to sugarcane: 7.4 million acres (10 % of cultivated land) Total Production: 4.2 BG ethanol The fiber in the stalks and leaves is used to generate process steam and electricity in the sugar mill. In addition, the liquid effluent (vinasse) is used as a fertilizer and irrigation supply to the cane fields, thereby eliminating cost of waste water treatment. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 B.- ETHANOL FROM SUGARCANE The Brazilian industry serves as a model in several ways: (1) The starting material is extremely cost effective. (2) The output can be quickly and cheaply adapted to changing market demands (ethanol or sugar). (3) The process is continuously optimized through research and development as exemplified by the significant economies already achieved by this industry. B.- ETHANOL FROM SUGARCANE The Sugarcane Plant: Sugarcane is a tropical grass belonging to the same tribe (Andropogoneae) as sorghum, and corn (maize). Modern sugarcane is a complex hybrid of two or more of the five species of the genus Saccharum. New Guinea is the original home of Saccharum officinarum. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Sucrose (Saccharose): The sugar of household and industry is sucrose, the most common sugar in the plant kingdom. Sucrose is the reservoir for the energy captured from the sun by the sugarcane leaves through photosynthesis, and sugarcane is the most efficient energy fixer per ton in the plant world. Composition of Sugarcane and Juice solids Sucrose Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Harvesting: The goal of harvest is to deliver sugarcane stalks of good quality to the mill. Quality, measured by sucrose and trash content, is reduced by: damaging cane, increasing trash in delivered cane, and delaying cane delivery. The removal of cane tops is highly desirable in the harvesting operation. Cane tops and leaves have little sucrose but are high in starch and reducing sugars. These tops and leaves lower sugar yields in the boiling house. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Harvesting: The top is most effectively removed by hand cutting, the harvesting method of choice in most of the sugarcane world. Because of labor shortage, in many developed nations the entire crop has been mechanically harvested for several decades. So far, the combine machine is only efficient for standing straight cane. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE FLOW DIAGRAM OF RAW SUGAR FACTORY Imbibition water Cane Bagasse MILLING PLANT Vacuum Phosphate JUICE PURIFICATION MUD FILTRATION EVAPORATION Final Molasses Raw Sugar CRYSTALLISATION Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE http://www.msfsugar.com.au/irm/Company/ShowPage.aspx?CPID=1076&EID=36187078 B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE CLEANING Cane - cleaning Equipment: Necessary where mechanical harvesting prevails. The cane on the carrier is deluged with warm water from the condenser system delivered through nozzles at high pressures. The wastewater, carrying the mud and much of the trash, is led off to the drainage system or is separately treated before final discharge. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE CLEANING AND EXTRACTION OF SUGARS The preparation of the cane for milling is accomplished in several ways: 1.- By revolving cane knives that cut the cane into chips but extract no juice. 2.- By shredders that tear the cane into shreds but extract no juice 3.- By crushers that break and crush the structure of the cane, extracting a large proportion of the juice. 4.- By combinations of any or all the means just enumerated Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE EXTRACTION OF THE JUICE Revolving cane knives Chopper fibrizer Tongaat shredder Shredder side Shredder feeding Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE EXTRACTION OF THE JUICE Crushers: Crushers in general consist of two (occasionally three) deeply grooved rollers that crush or break the cane, expressing from 40-70 % of the juice. The classical combination of three rollers arranged in triangular form is the standard milling unit for the industry. B.- ETHANOL FROM SUGARCANE EXTRACTION OF THE JUICE Compound imbition is used in all modern installations. As a rule the water or juice is applied to the bagasse as it issues from between the rolls with the idea that the bagasse will adsorb the liquid like a sponge in expanding. Cane Compound imbition Crushers Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE PURIFICATION OF THE JUICE Preliminary pretreatment: The juice from the mills is subjected to a coarse straining and further removal of suspended solids. Even after cane cleaning operations, juices may average 2-4 % insoluble solids, and wet weather 6-7 % is not uncommon. The material is mostly soil, sand, and ground rock that is not removed by preliminary screening. Continuous type settling devices in use in several factories are effective in removing coarser particles, but not clay and fine soil. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc 45o DSM juice screen B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE RAW SUGAR PROCESS AND EXTRACTION OF JUICE Purification of Juice (Clarification): The dark-green juice from the mills is ACID AND TURBID. The clarification process, designed to remove both soluble and insoluble impurities, universally employs LIME and HEAT as the clarifying agents. Milk of lime, about 0.5 kg CaO per ton of cane, NEUTRALIZES THE NATURAL ACIDITY OF THE JUICE, forming insoluble lime salts, mostly calcium phosphate. Heating the limed juice to boiling (95 oC) or slightly above COAGULATE THE ALBUMIN AND SOME OF THE FATS, WAXES, AND GUMS, and the precipitate thus formed entraps suspended solids as well as finer particles. The muds separate from the clear juice by sedimentation. The muds are filtered on rotary drum vacuum filters. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE PURIFICATION OF THE JUICE Function of a Clarifier: The function of a clarifier is to separate the INSOLUBLE PARTICLES FROM THE LIMES JUICE. The effectiveness of such removal is very often termed “turbidity reduction”. A good clarifier should not only produce good juice clarity, but also should have short retention time and more efficient mud removal. Any accumulation of mud that is not definitely scraped away will crust over rapidly and cool to a temperature that permits bacterial action and souring, resulting in sugar losses. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE JUICE CONCENTRATION Evaporation: The clarified juice, having much the same composition as the raw extracted juice except for the precipitated impurities removed by the lime treatment, CONTAINS ABOUT 85 % WATER. Two-thirds of this water is evaporated in vacuum multiple effects consisting on a succession of (four or five) vacuum boiling cells or “bodies” arranged in series so that each succeeding body has a higher vacuum, and therefore BOILD AT LOWER TEMPERATURE. The vapors from one body can thus boil the juice in the next one. By this system the steam introduced into the first body does multiple effect evaporation. The vapor from the final body goes into a condenser. Only part of the juice is concentrated up to 65 % sucrose, and final juice contains around 22 % sucrose. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE EVAPORATION Evaporator Types: A variety of multipleeffect evaporator types are used for raw sugar manufacture and refining. Calandria vessels are used in raw sugar manufacture. Long tube vertical rising film units are used for clarified juice evaporation in sugar manufacture. In order to avoid contamination in fermentation, juice is sterilized and cooled till fermentation temperature (28 oC) Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE EVAPORATION Multiple Effect Evaporator Vacuum Steam Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE PRODUCTION OF ETHANOL Ethyl alcohol can be produced from the sterilized juice. The fermentation results from the action of yeast, which first inverts the sucrose (to glucose and fructose) by the action of invertase secreted by the yeast. Then the yeast converts the invert sugar to ethyl alcohol and carbon dioxide. Fermentation is carried out at 28 oC to obtain wine with ethanol content of around 10 mass %. C12H22O11 + H2O + invertase = C6H12O6 + C H O 6 12 6 (Sucrose) (Fructose) (Glucose) C6H12O6 = 2 C2H5OH + 2 CO2 (invert (ethyl (carbon sugar) alcohol) dioxide) Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE Block-flow diagram of the ethanol production process from sugarcane Sugarcane Cleaning Sand, dirt, metals Extraction of Sugars Sugarcane Bagasse Juice Treatment Clarified juice Juice Concentration Juice Sterilization Yeast Fermentation Centrifugation Yeast Treatment Fermentation Gases Wine Adsorption CO2 Distillation and Rectification 2nd grade Alcohol , Vinasse, Fusel oil Dehydratation Anhydrous Bioethanol Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE CONVENTIONAL DISTILLATION SYSTEM Consist of a distillation column comprised by columns A, A1, and D and a rectification column comprised by columns B and B1. Pressure on the distillation columns range from 133.8 to 152.5 kPa, and from 116 to 135 kPa in the rectification columns. Dias MOS, Modesto M, Ensinas AV, Nebra SA, Filho RM, Rossell CEV: Improving bio-ethanol production from sugarcane: evaluation of distillation thermal integration and cogeneration systems. Energy xxx (2010) 1-13 B.- ETHANOL FROM SUGARCANE Micro-distillery: Microdistilleries have been developed by Brazil as small factories producing hydratated ethyl alcohol. This is an ultra-simple and comparatively inexpensive distillery which could be installed easily on any farm. Fermentation tanks Micro-distillery flowsheet Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE BAGASSE Bagasse is the byproduct or residue of milling cane. Bagasse amounts to one-third of the cane ground. It supplies the fuel for the generation of steam in the raw factories. Most modern factories have an excess of bagasse during the regular grinding season. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE BAGASSE The fuel value of dry bagasse is 8350 BTU/lb. The actual fuel value of bagasse burned on the grates depends on the moisture present. When bagasse contains moisture at the 53-54 % level, its heating value is reduced, and so is boiler efficiency. By pre-drying the bagasse using waste heat in the boiler flue gas, reducing the moisture to 46-47 %, not only may a great saving of supplementary fuel be expected, but also some 10-15 % of excess bagasse from total production may be available for other industrial purposes. Schematic diagram of the pneumatic bagasse drying system Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- ETHANOL FROM SUGARCANE BAGASSE Steam Boiler: The steam consumption per ton of cane varies widely depending on different factory equipment and product quality (450-550 kg steam/t cane). The most marked advanced in bagasse burning in the past 20 years has been the growing used of spreader stokers, particularly in connection with boilers of large capacity. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, B.- ETHANOL FROM SUGARCANE BAGASSE Bagasse Boards: It is now being used in practically all types of reconstituted panelboard, e..g., insulation board, process hardboard (wet or dry process), particleboard, and medium density board. The board forms by the process known in pulp handling as “felting” the strength of the board being due solely to the interweaving and entangling of the fiber. As the wet board comes from the forming machine, it is fed into a continuous hot-air drier, from which it emerges finished in a continuous sheet 12 ft wide, cut by saws into convenient sizes. Particle board is made from small pieces of lignocellulosic material with an organic binder agent under heat, pressure, or other treatments. Chen J.C.P., Chou C.C: Cane Sugar Handbook. A Manual for Cane Sugar Manufacturers and their Chemists.12th Edition, 1993, John Wiley & Sons, Inc B.- CELLULOSIC ETHANOL Production of first generation biofuels alone will not be able to satisfy the world’s growing energy needs. Giving the limits of corn and sugarcane ethanol, fuel ethanol production in the long run depend on the use of cellulosic materials as primary feedstocks. Over 1.3 billion dry tons of biomass from forest land and agricultural land alone are potentially available in the US every year. Such an amount is sufficient to meet more than one third of current demand for transportation fuels while still meeting food, feed and export demand. Production from cellulosic material is not yet a commercial route. Diluted acid hydrolysis, the currently available technology, has a limited efficiency of 35 %. PRETREATMENT TECHNOLOGIES ARE NEEDED! Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Simplified Diagram of Cellulosic Ethanol Production Girard P, Fallot A, Dauric F, Technology state of the Art, Forest Department of CIRAD C.- CELLULOSIC ETHANOL Concept 1 SEPARATE ENZYMATIC HYDROLYSIS AND FERMENTATION (SHF) NEW SYSTEM Biomass EXISTING SYSTEM FERMENTATION AT PRETREATMENT Sugars EXISTING CORN AND ETHANOL OR SUGAR HYDROLYSIS CANE ETHANOL PLANT Concept 2 DISTILLATION Ethanol SIMULTANEOUS SACCHARIFICATION AND FERMENTATION Biomass PRETREATMENT (Solubilization of hemicelluloses) HYDROLYSIS (Cellulose hydrolysis using Acid/enzymes) FERMENTATION (Conversion of sugars to ethanol by yeast) Ethanol DISTILLATION C.- CELLULOSIC ETHANOL SEPARATE ENZYMATIC HYDROLYSIS AND FERMENTATION (SHF) This process consist of two steps: the first step involves the enzymatic hydrolysis of pretreated cellulose into glucose, while the second step aims at converting the resulting glucose into ethanol. Enzymatic hydrolysis can be carried out under conditions optimum cellulose activity. The optimum temperature for hydrolysis by cellulase is usually around 50 oC, depending on the specific cellulase. Main shortcomings of SHF: 1.- The sugars produced strongly inhibit cellulase activity. 2.- Hydrolysis is a lenghty process and a diluted solution of sugar always bears the risk of contamination even at relatively high temperatures such as 50 oC. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL SIMULTANEOUS SACCHARIFICATION AND FERMENTATION (SSF) Combines the enzymatic hydrolysis of cellulose and the subsequent fermentation of the cellulose hydrolyzate in a single step. As soon as cellulose conversion into glucose is initiated, a fermenting microorganism is introduced in the medium and immediately consumes the produced glucose. Cellobiose and glucose significantly decrease the activity of cellulase. SSF therefore provides higher ethanol yields and requires lower amounts of enzyme than SHF, since end product inhibition from cellobiose and glucose produced by enzymatic hydrolysis is mitigated. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Disadvantages 1.- Cellulase is inhibited by ethanol 2.- Most micro-organisms used for converting cellulosic biomass (e.g. S. cerevisiae and Z. mobilis) preferentially use glucose and cannot efficiently utilize xylose and arabinose. 3.- It operates at temperature and pH conditions that represent a compromise between the optimal of these parameters for both enzymatic activity and the growth of the fermenting micro-organisms. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL PRETREATMENT TECHNOLOGIES Source: Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL PRETREATMENT TECHNOLOGIES Ammonia fiber expansion (AFEX) Ammonia recycle percolation (ARP) Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL HIDROLISIS Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Degradation of lignocellulosic biomass during pretreatment and the formation of inhibitory compounds. Cellulose Lignocellulosic biomass Hemicellulose Hexoses HMF Pentoses Levulinic acid Furfural Formic acid Furoic acid Acetic acid Ferulic acid Lignin Other aldehydes Other Acids Other phenols Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL CLASIFICATION OF INHIBITORS BASED ON THEIR CHEMICAL FUNCTIONAL GROUPS (1) Aldehydes , (2) Ketones, (3) Phenols, (4) Organic acids Low molecular weight compounds show more toxic effects to microbes than the high molecular weight compounds. This property could perhaps be explained by an easier transport of the smaller molecules via a variety of mechanisms including passive diffusion. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Aldehyde inhibitors (Furfural, phenol aldehydes such as 4-hydoxybenzaldehyde, coniferyl aldehyde, syringaldehyde and vanillins) are inhibitors to cell grow and ethanol yield for most yeasts and bacterial strains. Lignin derived aldehydes seems to be more inhibitor than those derived from cellulose. Ketone inhibitors: exert a greater inhibitory effect on bacteria such as thermoanaerobacter mathranii than on yeast in term of reduced grow and ethanol yield. Phenols such as cathecol, hydroquinone, and coniferyl alcohol almost completely inhibit E. coli. However, eugenol and isoeugenol are inhibitory to yeast at low concentrations. The general toxicity of a phenol compound to yeasts has been correlated to the degree of its methoxy substitutes ortho to the phenol hydroxy group. The order of inhibitory effect ranked from strong to weak is as follows: (1) hydroxyphenol (2) guaiacyl and (3) syringyl. Organic acids, in general are more toxic to isolates of bacteria than yeats. The toxicity of organic acids has been correlated with their degree of hydrophobicity, suggesting the involvement of a hydrophobic target such as the cell membrane. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL INHIBITORY COMPOUNDS DERIVED FROM LIGNOCELLULOSIC MATERIALS Overcoming the impact of inhibitory compounds derived from lignocellulosic biomass is one of the major challenges for a sustainable biomass to bio-fuels industry. Research and development in this area is under way in order to develop methods that limit the production of potential inhibitors produced during the deconstruction of biomass. Each of the currently available methods has different advantages and disadvantages. Remediation Treatments (Detoxification) Physical Chemical Bio-Chemical Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL INHIBITOR REMOVAL METHODS PHYSICAL: Vacuum evaporation (used to remove the amount of volatile compounds) (Concentrations of furfural, vanillin, and acetic acid can be reduced from 29 to 100 %) CHEMICAL: Precipitation of toxic compounds (such as alkali treatment using Ca(OH)2 or NaOH. By employing overliming the pH of the hydrolysate can be increased to 9 – 10 and subsequently readjusted to an appropriate value using acid addition prior to microbial fermentation). This method reduces aldehyde and ketone inhibitors, including furfural and HMF, improves microbial growth and fermentation performance. The formation of CaSO4 precipitation product must be removed. This additional step increases costs and generate an additional waste. Activated Carbon: Level of toxic compounds is reduced. BIO-CHEMICAL: Enzymatic treatment using peroxides and laccase from the lignolytic fungus Trametes versicolor has been reported to improve ethanol productivity of a fermentation process based on willow hemicellulosic hydrolysate. The soft-rot fungus Trichoderma reesei has been reported to be able to degrade inhibitory compounds in a hydrolysate after steam pretreatment. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL PERSPECTIVE The main challenges for cellulosic biomass based bio-ethanol process are: (1) The utilization of pentoses such as xylose and arabinose (2) The simultaneous utilization of glucose and pentoses (3) A lower sensitivity to fermentation inhibitors. Vertes A.A., Qureshi N, Blaschek H, Yukawa H: Biomass to Biofuels. Strategies for Global Industries. Wiley 2010 C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010. C.- CELLULOSIC ETHANOL Bura R, Gustafson R: Bioconversion of lignocellulosic biomass to ethanol: Challenges and opportunities. November 8, 2010.