AIR RECOVERY - Workspace - Imperial College London

advertisement

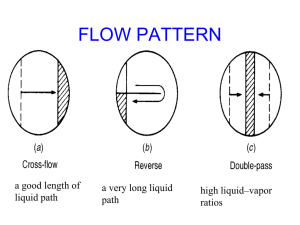

UNLOCKING OPTIMAL FLOTATION: is the AIR RECOVERY the key? Jan Cilliers Royal School of Mines Imperial College London Outline The Origins of Air Recovery • Modelling Flotation Froths • Useful froth equations Air Recovery Application • Measuring air recovery • Air rate effect and flotation performance • Bank air profiling using air recovery What is the Air Recovery? •Air leaves a flotation cell by bursting on the top of the froth or overflowing into the concentrate. Air leaving froth by bursting at top surface Air overflowing the weir as froth •The AIR RECOVERY is the fraction of the air that that overflows (and does not burst) Froth concentrate Air into the cell The Origins of Air Recovery • Modelling Flotation Froths • Useful froth equations Froth Flotation and Froth Physics The surface chemistry determines whether the minerals can be separated The froth physics determines how well the separation happens Requires a froth-phase model describing the physics A Flowing Froth Model - components • Froth motion • Liquid flow in the froth • Solids motion Froth Structure: The Physics of the Froth Films between bubbles Plateau borders Froth motion from pulp to concentrate Laplace equation gives velocity Boundary conditions: 1. Shape of tank and launders 2. Air entering the froth that overflows: AIR RECOVERY (%) Froth Flow in Radial Equipment Designs Liquid Flow in the Froth Three balanced forces act on the liquid in Plateau borders: Gravity, capillary and viscous dissipation 2 k 2 A 2 v A A x λ k2 A 2 A vx 2 A x x x x λ A k2 A v x A x x 2 2 v A k A A A y 2 k 2 A 2 λ 2k1 A A vy y 2 A y y y y λ A 2 k1 A k 2 A v y A 0 y y Liquid Motion and Content Solids Motion 1. Attached Solids Particles attached to bubbles move with the froth Most particles are detached due to coalescence (>95%) 2. Unattached Solids: Particles move in the Plateau borders Follow the liquid, settle and disperse Overflow into concentrate Mineral and Waste Particles Example of motion in Plateau borders Valuable Mineral Gangue Minerals Mineral grade in froth Froth Launder Design: Effect of forcing froth to flow inwards or outwards INTERNAL CHANNEL Internal Launder CHANNEL 1 CHANNEL 2 Two Launders Model validation Tracking particles in flotation using PEPT Model validation Tracking particles in flotation using PEPT Simplified Equations for Flotation Modelling Water flowrate to concentrate Entrainment factor Froth recovery (α<0.5) Water flowrate to concentrate Ql k Acolumn J d 2 bubble 2 g (1 ) ENTRAINMENT FACTOR Ratio of gangue recovery to water recovery 1.5 v h settling froth Ent exp D J g (1 ) Froth Recovery R froth J g v settling f 2 dbubble,in d bubble,out f 2 Froth Modelling Summary • Froth physics determines the effectiveness of the flotation separation • Complex froth zone simulators are available for operation and design • Simplified models have been developed for liquid recovery, froth recovery and entrainment, based on the physics All the froth models include THE AIR RECOVERY Air Recovery Application • Measuring air recovery • Air rate effect and flotation performance • Bank air profiling using air recovery Air recovery.. a reminder Air leaves a flotation cell by bursting on the top of the froth or overflowing into the concentrate. Air leaving froth by bursting at top surface Air overflowing the weir as froth The AIR RECOVERY is the fraction of the air that that overflows (and does not burst) Froth concentrate Air into the cell Measuring the air recovery Air leaving through bursting Overflowing froth height Air flowing over lip Air Recovery = Volumetric flowrate air overflowing Air flowrate into cell Air In Volumetric flowrate air overflowing = overflowing velocity x overflowing froth height x lip length Air Recovery shows a maximum (PAR) at a specific air rate Why is there a Peak in Air Recovery (PAR)? Optimum balance between froth stability and motion Air Recovery Bubbles heavily loaded Stable, but move slowly Bubbles under-loaded Unstable, burst quickly Air Velocity into Flotation Cell Predicting air recovery – theory 0.25 P * Crit 0.2 1 v *g 1 N v *g 0.15 0.1 v*g vg 0.05 vg ,int 0 P * Crit PCrit PCrit ,int 0 2 4 6 8 10 vg* 0 -0.05 -0.2 12 14 16 Air Recovery and flotation performance Air rate that gives highest air recovery also gives highest mineral recovery Froth appearance • Air rate 8m3 min-1 • Air rate 12m3 min-1 • Air recovery 70% • Air recovery 40% Why does the Air Recovery affect flotation? Optimum balance between froth stability and motion High recovery and grade Metallurgical Recovery Air Recovery INCREASE AIR REDUCE AIR Reduce grade Increase recovery Increase grade Increase recovery Bubbles heavily loaded Stable, but move slowly Bubbles under-loaded Unstable, burst quickly Air Velocity into Flotation Cell Air Recovery Application • Measuring air recovery • Air rate effect and flotation performance • Bank air profiling using air recovery Air rate profiling The air rate profile in a flotation bank affects the performance • Two strategies: 1. Determine the best air rate profile – Vary distribution of a set total air addition 1. Determine the optimal total air addition – Vary the total air addition with a set air profile 12 10 10 -1 12 Inlet air rate / m min 8 3 Inlet air rate / m3 min-1 Air rate profiling approaches 6 4 8 6 4 2 2 0 0 Balanced Increasing Decreasing Humped 1. Different air profiles with same total addition (e.g. Cooper et al., 2004) Low Intermediate High 2. Different air addition with the same profile (Hadler et al., 2006) Air Profiling Strategies 1. Determine the best air rate profile – Vary distribution of the total air addition – Increasing profile typically improves performance e.g. Cooper et al., 2004; Gorain, 2005; Hernandez-Aguilar and Reddick, 2007; Smith et al., 2008 1. Determine the optimal total air addition Determining the air rate profile • Increasing profile typically yields better performance Higher cumulative grade for same cumulative recovery (e.g. Cooper et al., 2004) Introduction: Previous work 1. Determine the best air rate profile 1. Determine the optimal total air addition – Best performance at air rate giving Peak Air Recovery (PAR) e.g. Hadler et al., 2006; Hadler and Cilliers, 2009 Cu Rougher Performance: 25% 35% 34% 33% 32% 31% 30% 29% 28% 27% 26% 25% 76.3% Cumulative recoveries: 75.6% 0% 20% 40% 60% 80% Cumulative Recovery (% Cu) As Found Peak Air Recovery 100% Cumulative air recovery (%) Cumulative Grade (% Cu) Grade-Recovery and Air Recovery 20% 15% 10% 5% 0% As Found Peak Air Recovery Study performed in two stages 1. Air rate profiling tests 2. Air recovery optimisation (PAR) tests First direct comparison of the two approaches Stage 1: Air rate profiles 1. Air rate profiling tests – Three profiles tested, the ‘Standard’ and two others, all adding same total air 2. Air recovery optimisation Air rate profiling: Air rate profiles Air flowrate / m 3 min -1 10 Profile 8 6 4 2 0 Standard Stepped Sawtooth Total air addition (m3 min-1) Standard 30.3 Stepped 28 Sawtooth 29.5 Air rate profiling: Performance 60 Standard Stepped Sawtooth Cumulative Air Recoverey / % Cumulative upgrade ratio 160 120 80 40 40 20 0 20 30 Cumulative recovery / % 40 0 D Stepped Sawtooth Standard Air rate profiling: Findings • Order of cumulative Cu recovery is same as cumulative air recovery – Sawtooth > Stepped > Standard Mineral recovery and air recovery qualitatively linked Stage 2: Peak Air Recovery test 1. Air rate profiling test 2. Air recovery optimisation – Preliminary tests to find PAR air rates – Test conducted at PAR air rates – Total air added same as ‘Standard’ profile Air recovery optimisation: Preliminary tests Air recovery / % 80% 60% 40% 20% Cell A Cell B 0% 5 7 9 Air flowrate / m3 min-1 11 Air recovery optimisation: Air rate profiles Air flowrate / m 3 min -1 10 Profile 8 6 4 2 0 Standard Stepped Sawtooth PAR Total air addition (m3 min-1) Standard 30.3 Stepped 28 Sawtooth 29.5 Peak Air Recovery 28 Air recovery optimisation: Air recovery Cumulative air recoverey / % 80 Standard Stepped Sawtooth PAR 60 40 20 0 A B Cell C D Air recovery optimisation: Performance Cumulative upgrade ratio 160 Standard Stepped Sawtooth PAR 120 80 40 0 20 30 40 Cumulative recovery / % 50 Air recovery optimisation: Performance of first cell • Effect of air rate: – Recovery maximum at PAR air rate – Upgrade ratio decreases with increasing air rate Air profiling using air recovery: Summary • Air profiling can significantly improve flotation performance • The performance improvement is a froth effect; rate kinetics alone cannot explain it • The air rate giving the highest air recovery (PAR) also gives the best flotation • The PAR method simultaneously determines the optimal bank air rate and distribution Summary and Conclusions • Froth physics determines the effectiveness of flotation • Froth models indicate important variables – this is the origin of AIR RECOVERY • Air recovery is affected by air rate; there is an air rate at which the air recovery is a maximum (PAR) • The Peak Air Recovery (PAR) methodology simultaneously establishes the correct air addition rate and the best air rate profile for a flotation bank • Significant improvements observed; plant control strategy Acknowledgements • Rio Tinto Centre for Advanced Mineral Recovery at Imperial College London • Froth and Foam Research team • Intellectual Property Rights • The peak air recovery-based froth flotation optimisation methodology is protected by a PCT-stage patent application, covering most of the countries of the world, with additional protection in Chile and Peru Questions? UNLOCKING OPTIMAL FLOTATION: is the AIR RECOVERY the key? Jan Cilliers Royal School of Mines Imperial College London