mechanical flotation machines

advertisement

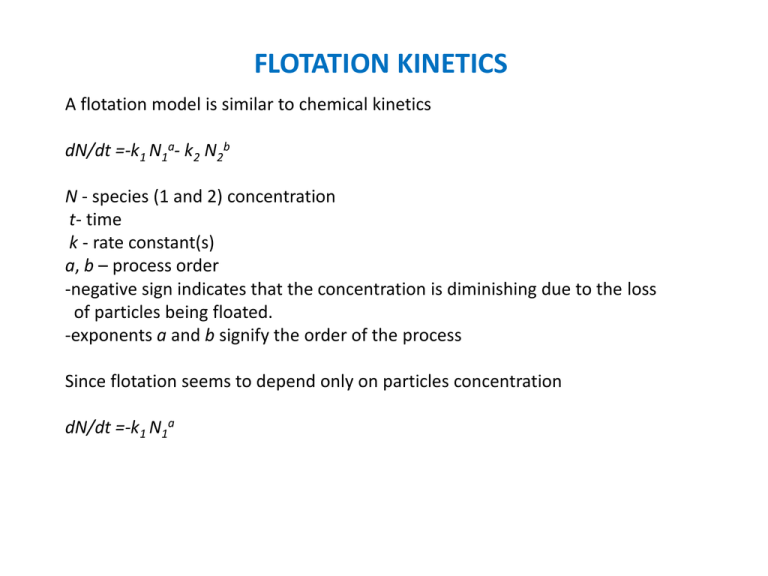

FLOTATION KINETICS

A flotation model is similar to chemical kinetics

dN/dt =-k1 N1a- k2 N2b

N - species (1 and 2) concentration

t- time

k - rate constant(s)

a, b – process order

-negative sign indicates that the concentration is diminishing due to the loss

of particles being floated.

-exponents a and b signify the order of the process

Since flotation seems to depend only on particles concentration

dN/dt =-k1 N1a

0

Flotation kinetics models

Model

Relation

= [1 – exp (–k1t)]

Classic first order

Modified first order

= {1 – 1/(k2t)[1 – exp (–k2t)]}

= [1 – 1/(1 + t/k3)]*

For reactor with ideal mixing

= k4t/(1 + k4t)*

Modified for gas–solid adsorption

= ()2 k5t/(1 + k5t)

Kinetics of second order

= {1 – [ln (1 + k6t)]/(k6t)}

Modified second order

= [1– { exp (–k7t) + (1 – ) exp(–k8t)}

Two rate constants

Distributed rate constants

* Equivalent models because k3 = 1/k4.

– flotation recovery after time t,

– maximum recovery,

– fraction of particles having lower flotation rate constant, k7,

k – flotation rate constant.

= [1 – exp(–kt) f (k, 0) dk]

Selected kinetic equations (ε – recovery of a component in separation product, εmax – maximum recovery of the

same component in separation product, k – rate constant of separation, t – separation time

Model

Formula

more

ε k t

Zeroth-order model

ε ε max 1 e

First-order model

First-order with rectangular distribution of

floatabilities

Fully mixed reactor model

-order model

2

Second-order model

Second-order model with rectangular of

floatabilites

k t

(2)

1

k t

ε ε max 1

1 e

k t

ε ε max

1

1

t

1

k

(3)

(4)

k t

ε ε max

1 k t

Improved gas/solid adsorption model

3

(1)

ε ε max

1

1

1

1 k t

2

ε

ε max

2

ε max

(5)

2

k t

1 ε max k t

1

ln 1 k t

ε ε max 1

k t

(6)

(7)

(8)

A. Bakalarz, J. Drzymala, 2013, Interrelation of the Fuerstenau upgrading curve parameters with kinetics of separation, Physicochemical

Problem of Mineral Processing, 49(2), 443-451

Flotation kinetics of the whole mass and components

40

yield of concentrate, γ, %

recovery of a component in

concentrate, ε, %

100

80

component 1

60

40

20

remaining components

30

20

sum of kinetics of

component 1 and

remaining components

10

0

0

0

10

20

separation time, min

components (recovery vs time)

30

0

10

20

separation time, min

30

product (yield vs time)

Flotation results plotted as a relationship between recovery of each component in

concentrate and separation time (a), yield of components forming concentrate vs.

separation time (b)

A. Bakalarz, J. Drzymala, 2013, Interrelation of the Fuerstenau upgrading curve parameters with kinetics of separation, Physicochemical

Problem of Mineral Processing, 49(2), 443-451

relation between flotation kinetics and upgrading curves

80

60

component 1

0

10

20

separation time, min

30

100

80

80

60

ideal upgrading

20

0

recovery of component 2 in

concentrate, ε2,c, %

ideal upgrading

100

40

recovery of component 1 in

concentrate, ε1,c, %

recovery of component 1 in

concentrate, ε1,c, %

100

Fuerstenau curve

40

20

0

0

60

20

40

60

80

100

recovery of component 2 in concentrate,

ε2,c, %

40

component 2

20

0

0

10

20

separation time, min

30

b

a

The kinetics of separation of feed

components (a) provide separation

results in the form of

the Fuerstenau upgrading curve (b).

A. Bakalarz, J. Drzymala, 2013, Interrelation of the Fuerstenau upgrading curve parameters with kinetics of separation, Physicochemical

Problem of Mineral Processing, 49(2), 443-451

ugrading curves (here Fuerstenau’s) equations based on kinetics of flotation

1, c

0

3

1

2 ,c

ε 2 ,c

ε

k' ln

1 ,c

100

ε

k ε

1 ,c

2 ,c

0

4

ε

1

1 ,c

ε 2 ,c

100

k ln

ε

1 ,c

1

ε

100 1

1 ,c

2

(1 5 k ε

)

2 ,c

100 ε 2 ,c

100

100 1

2

2

1

ε

100 1

1 ,c

100 ε 2 ,c

1 5 k ln

100

k

k' ε

ε

1 ,c

2

100

ε

1 ,c

2 ,c

100 (100 ε

2

2 ,c

)

100 ε 2 ,c

100

k ln

100 ε 2 ,c

100

100 k ln

1

7

3

2

1

ε

100 1

1 ,c

2

(1 5 k' ε

)

2 ,c

1

ε

100 1

1 ,c

100 ε 2 ,c

1 5 k' ln

100

2

ε

100 1

1 ,c

1

2

k (10 100 ε

)

2 ,c

1

100 ε

2

,c

ε

100 1

1 ,c

1

k' ε

2 ,c

1

20 (100 ε

2 ,c

)

2

9

ε

1 ,c

2

k ε

100

2 ,c

100 (100 ε

ε

2 ,c

)

1 ,c

2

100 ε 2 ,c

100

k' ln

100 ε

100 k' ln

100

2 ,c

1

c,1 recovery of component 1 in concentrate

ε

100 1

1 ,c

1

2

k ε

2

,c

1

20 (100 ε

)

2 ,c

ε

1 ,c

100 k ε

ε

2 ,c

2 ,c

( k 1) 100

13

c,2 recovery of component 2 in concentrate

Theoretical shape of the separation data in the Fuerstenau plot

recovery of component 1 in concentrate, ε1,c, %

100

100

recovery of component 1 in concentrate, ε1,c, %

recovery of component 1 in concentrate, ε1,c, %

100

80

k=1.5

k=1

k=3

60

40

k=0.5

20

80

k=2

k=1

60

k=5

k=0.4

40

20

20

40

60

80

0

recovery of component 2 in concentrate, ε2,c, %

k=0.5

60

40

k=0.02

20

k=0.005

0

0

100

80

0

0

0

k=1

20

40

60

80

recovery of component 2 in concentrate, ε2,c, %

4*

7

100

20

40

60

80

recovery of component 2 in concentrate, ε2,c, %

100

9

13

recovery of component 1 in concentrate, ε1,c, %

100

Remeber: for characterizing separation results we need

either two parameter or a law governing separation and

then you can use one parameter which can be called

selectivity as in these plots selectivity k

80

k=1

k=3

60

k=0.5

40

k=0.2

20

0

0

20

40

60

80

recovery of component 2 in concentrate, ε2,c, %

100

*for a suitable equation see previous slide

(more plots in A. Bakalarz, J. Drzymala, 2013, Interrelation of the Fuerstenau upgrading curve parameters with kinetics of separation,

Physicochemical Problem of Mineral Processing, 49(2), 443-451

An example of separation results approximation using the Fuerstenau plot

ideal upgrading

100

100

80

p la n t 3 , tria l 1

a = 1 0 2 .2 8

r

60

= a (1 0 0 - r )/(a - r )

40

20

0

80

a=100

(c o m p o n e n t 1 in p ro d u c t 1 )%

F = (89/89)

60

no upgrading

40

20

0

0

20

40

60

80

100

Polish copper ore – lab tests with xanthate

0

20

40

60

component 2 in product 2,

80

%

100

Homework

Calculate the rate constant and order of a set of yield flotation data

Microlaboratory cells

Laboratory cells

Laboratory machines

Industrial machines

Mechanical

Pneumo-mechanical

Pneumatic

Pressurized (DAF)

Other (sparged hydrocyclone, ASH)

Laboratory cells

water level

magnetic stirrer

porous glass

gas

deflector

froth

product

water level

x

stirrer

porous glass

gas

Other laboratory flotation devices

a) cylindrical cell equipped with magnetic stirrer (Fuerstenau, 1964)

b) laboratory flotation device of Partridge and Smith, 1971

flotaton product

drive

air

Laboratory Mechanobr flotation machine

Laboratory Denver flotation machine

Industrial flotation

EIMCO Product Leaflets, 2000

Flotation machines are used individually and as a group (bank)

Flotation machines are rectangular and circular

Svedala Product Handbook, 1996

Constructions and impellers of flotation machines are different

Denver

Mechanobr

Fagergreen (WEMCO-EIMCO)

DENVER

Wemco-Fagergreen (V=0.085 ÷ 85m3)

Kelly E.G., Spottiswood D.J., Introduction to mineral processing. J.Wiley& Sons, N.Jork 1985

Wemco-Fagergreen (WEMCO-EIMCO)

mechanical flotation machines

EIMCO Product Leaflets, 2000

Denver

Agitair

Metso RCS (Metso Minerals)

Outotec (Outokumpu)

X-Cell (FLSmidth Minerals)

Humbolt-Wedag

IMN Gliwice

Fragment of mechano-pneumatic flotation machine

(continueous, multi-impeller tankless Denver D-R

Wills B.A., Mineral processing

technology. Pergamon Press 1983

tailing

Pneumo-mechanic multi-tank (15m3 each)

(Aker FM – Humbold Wedag)

Humbold-Wedag Product Leaflets, 1998

Pneumo-mechanical flotation machines IMN

Maszyna przepływowa

wielowirnikowa

Maszyna

jednowirnikowa

New machines: large volume and output, saving energy

Historyczny rozwój pojemności maszyn flotacyjnych

Flotation technologies. Outotec Leaflets 2007

(Outokumpu OK-100, V= 100m3

TankCell 300

300m3

Outokumpu Oy Leaflets 2000

Flotation technologies, Outotec Oyj. Leaflets 2007

Outotec TankCell 500 (500m3)

© 2012 Outotec Oyj. www.outotec.com

RCS™ (Reactor Cell System) from 5 to 200 m3 (Metso

Minerals/Svedala)

1-radial flow of

slurry to tank

wall

2-primary slurry

stream to

benith impeller

3-secondary

recirculation

towards upper

part of tank

Basics in mineral processing. Metso

Minerals 2003

RCS™ (Reactor Cell System) from 5 to 200 m3 (Metso Minerals)

Basics in mineral processing. Metso Minerals 2003

RCS™ (Reactor Cell System) from 260 m3 (Metso Minerals)

pneumo-machanic

XCELL (FLSmidth Minerals)

XCELL™ Flotation Machines. FLSmidth Mineralss brochure 2008.

FLOTATION COLUMNS

Metso

Outotec (Outokumpu)

Jameson Cell

Imhoflot

Pneuflot (Humbolt-Wedag)

Injection Jameson Cell

Pneumatic PNEUFLOT

Pneumatic flotation with PNEUFLOT® cells HUMBOLDT WEDAG leaflet 2009

Multi-injection Imhoflot 3 (centrifugal flotation)

feed

compressed

air

air plus

suspension

feed

reagents

concentrate

tailing

feed pump

tailing pump

Pneumatic cell Imhoflot. Maelgwyn Mineral Service leaflet 4/06 Chile 2006

Injection column

Siemens

SIMINE Hybrid Flot

Metals and Mining, Siemens VAI, No. 1, 2011

Dissolved air flotation (DAF)

Dissolved air flotation (DAF)

Flotation, ZWR Polkowice