Working Principle

advertisement

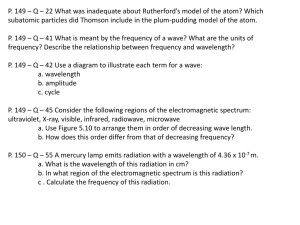

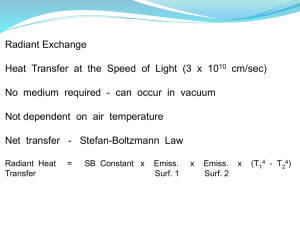

Schedule of discussion topics 1. Advantages of non-contact temperature measurement 2. Physical principles of non-contact temperature measurement 3. Definition and influence of emissivity 4. Fundamentals of optics 5. Applications and solutions 6. References 7. Criteria for selecting a pyrometer 8. Gobal features of KELLER pyrometer 9. Introduction of the series CellaTemp PQ/PL and PA Chapter 1 Advantages of non-contact temperature measurement Advantages of non-contact temperature measurement ▪ ▪ ▪ ▪ ▪ ▪ The technique employs non-wearing equipment. Quick (takes only milliseconds). Measurement of moving targets is possible. Enables measurement of hazardous or inaccessible objects. Measurements as high as 3500°C are possible. Nondamaging technique; especially suitable for poor heat conductors, very small objects, sensitive surfaces or hygienic products. Chapter 2 Principles of non-contact temperature measurement A pyrometer is used for temperature measurement but it doesn´t measure the temperature Physics of non-contact temperature measurement All matter that has a temperature (T) greater than absolute zero emits electromagnetic radiation (photon particles) due to the internal mechanical movement of molecules. These photons travel at the speed of light and act according to well-known optical principles. They can be deflected, focused with a lens, or reflected from reflective surfaces. Radiation thermometers or pyrometers are measurement instruments which determine the temperature of an object based on the infrared radiation emitted from that object. Thermal radiation radio infrared visible ultraviolet The spectrum of radiation useful for pyrometric measurement ranges from 0.65 µm to 20 µm wavelength We refer to this range as infrared radiation because it lies within the red area of visible light Planck´s Radiation Law 1,0E+04 Spectral radiance [W / cm³ µm] 1,0E+03 1,0E+02 5500K (5326°C) Max Planck, 1858 - 1947 3000K (2726°C) 1,0E+01 1,0E+00 1500K (1226°C) 1,0E-01 800K (526°C) 1,0E-02 1,0E-03 500K (226°C) 1,0E-04 200K (- 73°C) 1,0E-05 0,1 1 10 Wavelength[µm] 100 Atmospheric transmission in the infrared spectrum 100 Transmission [%] 90 80 70 60 50 40 1m 30 20 10m 10 0 0 1 2 3 4 5 6 7 8 Wavelength [µm] 9 10 11 12 13 14 Temperature to wavelength relationship ▪ ▪ Depending on the specific sensor, filter, and design of the pyrometer, only the radiated energy within a narrow wavelength band will be detected and converted into a quantity proportional to temperature. The choice of the wavelength for a pyrometer depends primarily on the temperature range to be measured. Temperature range Wavelength -30 ... 1000 °C 100 ... 800 °C 180 ... 2500 °C 500 ... 3000 °C 600 … 3000 °C 8 ... 14 µm 1,8 ... 2,2 µm 1,1 ... 1,7 µm 0,8 ... 1,1 µm 0,85 … 0,91 µm Measurement errors due to transmittance reduction ▪ ▪ Under actual conditions, a pyrometer´s sensor will not always receive the entire amount of thermal radiation emitted from the target object. Obstructions such as steam, dust, sight glasses or equipment within the instrument´s optical path will reduce the radiation reaching the pyrometer. Messobjekt Ideale Bedingungen Sichtkegel Pyrometer Dampf, Staub Reale Bedingungen Emittierte Strahlung Pyrometer Partikel, Gase Sichtfenster Festes Hindernis One-Colour Pyrometer radiatoin M(λ1) * ε1 T l1 •0,1 •1 wavelength [µm] •10 •100 Two-Colour Pyrometer radiation M(λ1) * ε1 T M(λ2) * ε2 l1 •0,1 l2 •1 wavelength [µm] •10 •100 Block diagram CellaTemp PZ as two-colour pyrometer 11 7 l1 8 9 10 A A A MP D l2 D 12 1 2 3 4 5 6 1 measured object 5 ocular 9 A/D converter 2 lens, colour corrected 6 polarisation filter, adjustable 10 microprocessor 3 semitransparent mirror 7 detector 11 D/A converter 4 target marking 8 preamplifier 12 serial interface The behaviour of a one-colour and two-colour pyrometer due to reduction the infrared radiation two colour channel Quartz window t = 94 % channel l1 channel l2 sieve t = 20 % Contamination of a quartz glass window Contamination detection target object steam/dust obstruction to sighting path sighting tube/ kiln wall debris protective window soiling Pyrometer CellaTemp PZ with integrated contamination detection function alarm signal Chapter 3 Definition and influence of emissivity Definition of emissivity „black body“ „real radiator“ =0 =0 =1 ++=1 Emitted radiation = Absorbed radiation Emitted radiation of a real body (R) Emissivity (ε) = Emitted radiation of a black body (S) Components of radiation as detected by a pyrometer Target object Transmitted background radiation * Obj. Pyrometer * Back * Amb. Reflected ambient radiation The radiation consists of the following components: =( * Obj.) + ( * Amb.) + ( * ΦBack) Emissivity of the target object Reflection of the target object Transmission of the target object Emissivity based on material and wavelength Emissivity depending on temperature Measurement errors At 1% change in emissivity or pollution, depending on temperature and wavelength 16 4.5-4.9µm 8-14µm 14 Messfehler [°C] 12 1.9-2.5µm 10 8 1.1-1.7µm 6 0.78-1.06µm 4 0.63-0.67µm 2 0 0 500 1000 1500 Temperatur [°C] 2000 2500 3000 Chapter 4 The Fundamentals of Optics Target spot diameter in reference to the radiant energy received d(95%) d(90%) The spot diameter is expressed as a percentage of the radiant energy emitted. d (95%) 3 x d (90%) Distance ratio d a Definition: distance ratio (D) = distance (a) target spot diameter (d) With focusable optics, the maximum permissible measuring distance is the distance ratio multiplied by the target spot diameter. Energy distribution of an imaged point source at best focus defocused by 0.5 mm Chromatic aberration of lenses relative change in focal length [%] 1 single lens made of crown glass 4,00 3,00 2 achromat cemented for the visible range 3 achromat cemented for the infrared range 1 2,00 2 1,00 0,00 3 -1,00 -2,00 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 wavelength [nm] Size of Source Effect for well and bad focusing well focusing bad focusing 910 900 temperature [°C] 890 880 870 860 850 840 830 820 810 800 0 5 10 15 20 25 target diameter [mm] 30 35 40 Chapter 5 Applications and solutions Application rolling mill stand Detect and document rolling temperature before and after the rolling stand. Solution One-colour pyrometer with a short wavelength and narrow wavelenght band Two-colour pyrometer with a short response time and focusable, precision optics Application blast furnace Application continuous caster Knowing the strand temperature is important for optimizing cooling rates and controlling process speed. A pyrometer with fiber optics can be employed for temperatures up to 250 °C without cooling Application strip galvanizing Pyrometers measure temperatures of metal strips and sheets before they pass through the molten zinc bath and during coiling. Measurement target within the gap Application: Continuous extrusion of aluminium The temperature is controlled by using the CellaTemp PA 29 pyrometer with a special wavelength to eliminate reflection ration CellaCast - Measurement systems for non-contact and nonwearing temperature measurement of continuous liquid iron streams of discontinuous pour streams 2-3 Customer typology Examples of pyrometer customers / applications (1) Rolling mill Centrifugal casting Heat treatment Billet heater Asphalt mixing plant Cement production 2-3 Customer typology Examples of pyrometer customers / applications (2) Bulb production Float glass production Crystal growing furnaces Bottle glass production Soldering machines Frozen foods monitoring Criteria for selecting a pyrometer Global features of KELLER pyrometer Introduction CellaTemp PQ / PL Introduction CellaTemp PA Thank you for your attention ?