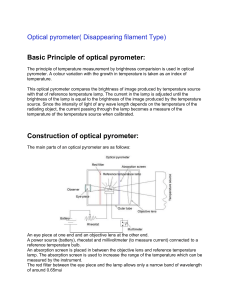

Pyrometer- Handbook

advertisement