Characterizatio aze Joints-Ryan Kraft

advertisement

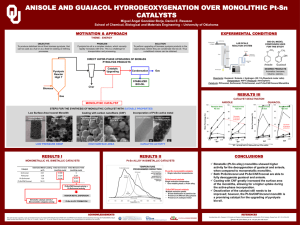

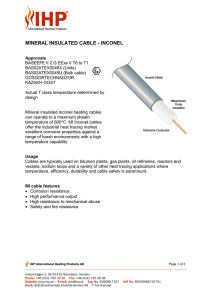

Characterization of Inconel 625 Superalloy Braze Joints using 4 Different Brazes Ryan Kraft, and Rajiv Asthana, University of Wisconsin-Stout Objective and Significance Experimental Procedure Our research investigates how the process of brazing modifies the original braze composition and braze metallurgy in the vicinity of joined interfaces and how braze alloys modulate the structure, composition and metallurgical adhesion to substrates. 1. Cut Inconel on high-speed precision saw, lay braze foil at mating surface, apply a load (0.30-0.40 N) during brazing. Developing and demonstrating methods to braze high-temperature alloys are the practical goals of our broader research effort. Background Inconel 625 (melting point: 1350°C) is a general purpose nickel-chromiummolybdenum alloy in the family of Inconel alloys that were developed for elevated temperature use. Inconel 625 has good corrosion and oxidation resistance which makes it suitable for harsh environment applications. Inconel alloys are used in a wide variety of applications, from gas turbine blades and heat exchangers to NASCAR exhaust systems and X-15 rocket planes. In applications, Inconel must be joined to itself or to other alloys to make complex assemblies . 2. Heat under vacuum (~10-6 torr) to 15-20C above braze TL. After 5 (or 30) min. soak, slowly cool. 4. Mount joints in epoxy, grind, polish and examine joint microstructure using optical microscopy (OM) and scanning electron microscopy. KHN = 252 5. Measure Knoop hardness (Buehler Micromet 2001 Unit, 100 g load, 10 s). KHN = 415 100 μm KHN = 278 Composition and Properties of Brazes Braze MBF-20[b] Inconel The microstructure of the Inconel MBF-20 braze joint show many layers within the reaction layer, similar to that of MFB-30. The hardness of the braze was lower than that of the substrate’s. 3. Heat treat joints in air at two-thirds of absolute braze melting temperature for 45 min. completed at UW-Stout. MBF-30[b] Braze Inconel/Inconel Joint with MBF-30 Braze (R2, 1045 C, 5 min) TiCuSil[a] CusilABA[a] Comp., % TL, K TS, K YS, MPa --- CTE, x10- K, W/m.K %El 6 K-1 ---- Ni-4.61Si-2.8B0.02Fe-0.02Co Ni-6.48Cr-3.13Fe4.38Si-3.13B 1257 1327 E, GPa -- 1242 1297 -- 68.8Ag-26.7Cu4.5Ti 63Ag-35.3Cu1.75Ti 1173 1053 85 292 18.5 219 28 1088 1053 83 271 18.5 180 42 -- -- Joint Microstructure vs. Knoop Hardness Profile Inconel/Inconel Joint with Ticusil Braze (R19, 920 C, 5 min) KHN = 335 Reaction Layer -KHN = 121 KHN = 660 100 μm [a]Morgan Advanced Ceramics, [b]Honeywell, Inc., TL: liquidus temperature, TS: solidus temperature, E: Young’s modulus, YS: yield strength, CTE: coefficient of thermal expansion, K: thermal conductivity, El: percent elongation. Inconel Sample and Identification Research Approach •Demonstrate vacuum brazing of Inconel 625 using four brazes of different compositions . •Characterize joint microstructure using optical microscopy and scanning electron microscopy, and hardness distribution using the Knoop test. •Heat treat vacuum-brazed joints in air at two-thirds of the absolute melting point of braze to simulate service conditions and characterize microstructure and hardness. •Heat treat unbonded braze foils and compare through-thickness braze microstructure, composition, and hardness with microstructure, composition, and hardness of braze foils in joints. •Analyze metallurgical changes that occur in brazing and subsequent heat treatment, and compare and contrast effectiveness of different braze compositions to join Inconel 625. Sample ID Substrates Braze alloy R2 Inconel/inconel MBF-20 Braze Temperature(°C) 1045 R4 Inconel/inconel MBF-30 Inconel/Inconel Joint with Cusil-ABA Braze (R9, 835 C, 5 min) Time(min) Weight(g) 5 40 1045 5 Inconel/inconel Cusil-ABA 835 5 40 R19 Inconel/inconel Ticusil 920 5 110 KHN = 335 KHN = 87 Results and Data 100 μm Inconel/Inconel Joint with MBF-20 Braze (R4, 1045 C, 5 min) The microstructure of the MBF-20/Inconel braze joint contained multiple layers within the reaction layer. The hardness of the inner brazed region was very high, while the other layers were softer than the surrounding Inconel substrate. KHN = 321 KHN = 501 The Cusil ABA/Inconel reaction layer was very narrow. Although the region is visible no hardness data could be obtained. 40 R9 KHN = 1197 Cu-Ag System (base alloy for Cusil-ABA and Ticusil) Joint Microstructure Reaction Layer Binary Phase Diagrams of Major Braze Constituents Ni-Cr System (base alloy for MBF-20) Knoop Hardness profile across braze joint It appears that the microstructure of the Ticusil/Inconel interface contains a reaction layer extending from the brazed region into the Inconel substrate along the Inconel’s grain boundaries. The reaction layer was much harder than the braze region or Inconel substrate. Knoop Hardness profile across braze joint Joint Microstructure showing eutectic structure Continuing Research -Complete microstructure characterization using scanning electron microscopy and elemental analysis of brazed joints using energy dispersive spectroscopy -Complete polishing, microscopy, elemental analysis and microhardness of unbonded braze foils (heat treated and non-heat treated). Compare and contrast with the behavior of heat treated and non heat treated braze foils within joints. -Measure shear strength of joint. 100μm KHN = 281 Joint Microstructure vs. Knoop Hardness Profile Acknowledgement • NASA Glenn Research Center, Ceramics Branch, for the materials used in the study and for use of high vacuum brazing furnace. l