NESCC 14-039 - S. Anderson Presentation on Laser Direct

advertisement

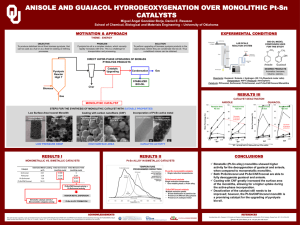

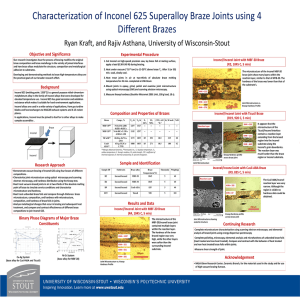

Laser Direct Manufacturing of Nuclear Power Components Dr. Jyotsna Iyer, Dr. Scott Anderson, Gautham Ramachandran, Georgina Baca, Scott Heise, Dr. Slade Gardner 3 November 2014 Acknowledgment: “This material is based upon work supported by the Department of Energy , Office of Nuclear Energy, Idaho Operations, under Award Number DE-NE0000542” Disclaimer: “This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.” Nuclear Energy in the U.S. – 4 new plants under construction in U.S., >60 globally, >150 on order • Current Light Water Reactors (LWR) cost $10B$12B/unit – Costly on-site construction 300 Gigawatts -electric • 104 reactors in the U.S. providing 20% of our electricity 200 100 0 2010 2020 2030 2040 2050 Current reactors, 40 years Current reactors, 60 years New capacity being considered 4 Builds per year starting 2021 Generating capacity with 80-year life • Next generation Small Modular Reactors (SMR) estimated $800M-$2B/unit – DOE SMR program funding ~$400M – B&W and NuScale selected for concept development – Factory fabrication, rapid installation • Advanced materials and manufacturing are significant industry drivers Advanced/Affordable Manufacturing methods are key enablers for competing in $700B global market 2 DOE Nuclear Energy Enabling Technologies (NEET) Advanced Manufacturing Methods (AMM) Contract: DE-NE0000542 POP: 36 months, GFY13 - GFY15 DOE Team: Alison Hahn (HQ), Jack Lance (HQ), Bradley Heath (HQ) LM Team: Gautham Ramachandran, Dr. Scott Anderson, Dr. Jyotsna Iyer, Georgina Baca, Scott Heise, Dr. Slade Gardner Dr. Eric Faierson, Quad City Manufacturing Laboratory Scope Purpose: Position U.S. to compete in $B international market for nuclear power via enabling technology that significantly reduces development and operational costs and manufacturing lead time for nuclear reactors Project Objectives: Demonstrate >50% cost and schedule reduction using additive manufacturing methods. Develop, advanced radiation tolerant alloys via nanophase modification during additive manufacturing for reduced life cycle costs. HIGHLIGHTS LM CE&T Energy IPT funding costshare and supporting industry engagement and growth opportunities Net-Shape Manufacturing Demo Articles built in <18 hours, no assembly/joining required – Fuel rod spacer grids manufactured using 316L SS and Inconel600 Laser Melting Sintered powder Technical Approach • Build manufacturing demonstrations of complex parts demonstrating design flexibility and shortened design-to-manufacturing cycles • Employ nanophase alloy modification via Laser Direct Manufacturing (LDM) to create enhanced radiation tolerance in the components • Demonstrate the cost and schedule benefits through case studies and business case analyses (Unsintered powder) Completed Layer Background for Alternate Nuclear Materials Selection Fuel Assembly 1400 Fuel Rod Cutaway Very High Temperature Reactor 1200 Fuel Pellets Superficial-Water-Cooled Reactor Fuel rod Gas Fast Reactor 100 Lead fast Reactor Clad Molten Salt Reactor Temperature (°C) 800 Spacer grid 600 400 Fuel pellet Sodium Fast Reactor Generations II-III 200 UO2 MOX 0 0 50 100 150 200 Displacements Per Atom (dpa) N13137-01 N13137-02 Water flow 4 Table of Comparison Criteria for Selection of Alternative Nuclear Materials Comparison criteria • Low neutron absorption • Elevated temperature mechanical properties – Creep resistance – Long-term stability – Compatibility with reactor coolant • Resistance to irradiation-induced damage (greater than 200 dpa) –Radiation hardening and embrittlement –Void swelling –Creep –Helium-induced embrittlement –Phase instabilities Alternate Nuclear Materials • BASELINE: Traditional ferritic/martensitic steels (HT-9) or later generations of F/M steels • OPTION 1: ODS steels to examine effect of direct manufacturing methods on nanoscale oxide domains • OPTION 2: Inconel 800 series of materials to study the effect of processing parameters offered by direct manufacturing methods to improve performance under irradiation • OPTION 3: Among the refractory alloys, the Mo (TZM) alloys. These have a high operating temperature window and also, the most information on irradiated material properties Based on customer feedback at Technical review, materials down-selected to 316SS, ODS steels and Inconel alloys 5 Material Down selection for DM Demonstration • Alloys: Inconel 600, Inconel 718, Incoloy 800, 316L SS, ODS Steels • Oxides: Yttrium, Cerium - Mix of nano- & micron- sized oxide particles selected for mixing 10 x 10 Grid 10 x 10 Grid 3 x 3 Grid Emerging literature in Austenitic ODS alloys • Development of Austenitic ODS Strengthened Alloys for Very High Temperature Applications (http://energy.gov/sites/prod/files/2013/09/f2/Stubbins_Austenitic%20ODS%20NEUP.pdf) • Synthesis and Characterization of Austenitic ODS alloys (http://www.mme.iitm.ac.in/murty/?q=node/96) 6 Process Parameter Variation During Part Fabrication – Inconel 600 Specimen size Scan speed Inconel 600 1cmX2cmX1cm 1100mm/s Inconle 718 1cmX2cmX1cm 1200mm/s 1cmX2cmX1cm 1cmX2cmX1cm 1cmX2cmX1cm 1cmX2cmX1cm 1cmX2cmX1cm 1000mm/s 900mm/s 800mm/s 1200mm/s 1400mm/s Laser power 195W 195W Standard EOS Standard EOS 195W 195W 195W 195W 195W 165W 165W 165W 165W 165W 180W 180W 180W 180W 180W 150W 150W 150W 150W 150W 7 Process Parameter Effect on Fabricated Part Density – Inconel 600 Laser power of 195W makes the fabricated article almost insensitive to scan speed 8 Process Parameter Effect on Fabricated Part Density – Inconel 718 Laser power of 165W most consistent for Inconel 718; more scatter in density data 9 Microstructure Characterization Sample # Sample name Micrograph (100X) Density (g/cm3) Proces Parameters Notes: Power (W) Speed (mm/s) 4 600_150_1400 8.235 150 1400 10 600_180_1400 8.299 180 1400 11 600_195_800 8.384 195 800 12 (a) 600_195_1100 8.37 195 1100 Sample #12 was selected to be mounted in both the x-y & Z planes (long) 12 (b) 600_195_1100 8.37 195 1100 Sample #12 was selected to be mounted in both the x-y & Z planes (trans) 14 600_195_1400 8.346 195 1400 QCML manufactured 56 of Inconel 600 samples Fourteen were selected Five samples were selected for microstructure characterization Sample #12 was selected for mounting in both the x-y & z directions for a total of six samples Metallography Procedure Mount/ grind/ polish Micrograph (photographs) Scanning Electron Microscopy (SEM) Etch Micrograph SEM Samples produced at the higher speed rate and lower power demonstrate more voiding based micrographs 10 Backscattered Electron Imaging of Sample 600-195-1400 Top Bottom Middle • BSE imaging revealed the solidification/grain microstructure • Microstructure appeared similar in the three locations examined • No titanium nitride particles were detected (titanium nitride particles are typically found in wrought material) • Black areas in images are voids 11 Microstructure Comparison of Inconel 600 Bar Stock Sample vs Additive Manufactured Sample • QCML manufactured 56 of Inconel 600 samples • Fourteen were selected • Five samples were selected for microstructure characterization Metallography procedure • • • • • • Inconel 600: Bar Stock Sample 500X BSE 10kV not etched Mount/ grind/ polish Micrograph (photographs) Scanning Electron Microscopy (SEM) Etch Micrograph SEM Inconel 600: Sample 500X BSE 10kV not etched Noticeable Grain Structure differences due to manufacturing process 12 Examination of Microstructure of Edge Transition Top Edge: Terminating Side (a) (b) Top Edge:500X Terminating Side Side (c) Top Edge Transition: 500X Initiating Side Side a) Inconel 600 Micrographs show (b) top edge (c) transitions (d) interior of sample at 500X (d) Away from edge: 500X 13 Test Coupons Ready for Mechanical Testing Inconel 600 longitudinal, transverse, and 45deg specimen blanks after LDM • This build layout produces 45 test coupons in a single build at 1100mm/s and 195W • The test coupons are cylinders with 0.5" diameter by 3" length. • 15 cylinders are in horizontal orientation • 15 cylinders are in vertical orientation • 15 cylinders are at 45 degrees with respect to the horizontal. Samples heat treated (900C for 1-2hr) to remove after fabrication to prevent warping 14 Next Steps • Mechanical & microstructural characterization of test coupons for Alloy 600 • Test specimen build for Alloy 718, Alloy 800 • Characterization of Alloy 718 & Alloy 800 test specimens • Test coupon build for Alloy 718 & Alloy 800 • Mechanical & microstructural characterization of test coupons for Alloy 718 & Alloy 800 • ODS steel mechanical blending & trial runs 15 Back up slides 16 Metallurgy of AM Technologies • Weldable alloys are readily manufactured via AM – Titanium alloys, stainless steels, alloy/tool steels, nickelbased alloys (Inconel), cobalt-based alloys • Enables unique control of microstructure – Very fine grain sizes due to high solidification rates – Can produce microstructures not possible using conventional manufacturing methods • Equivalent or superior mechanical properties to wrought alloys 17 Material Down Selection for DM Demonstration Alloy Inconel 600 Inconel 690 Procurement Status 250lbs in-house Inconel 718 Inconel 625 250lbs in-house Incoloy 800 Incoloy 800H Purchased from Carpenter expected ship date 9/17 316 SS 316Ti SS 316L SS 304 SS ODS Steels T91 In-house Correct particle size not available Oxide list downselected further details being worked out • Mix of nano- and micron- sized oxide particles selected for mixing with 316SS Emerging literature in Austenitic ODS alloys • Development of Austenitic ODS Strengthened Alloys for Very High Temperature Applications (http://energy.gov/sites/prod/files/2013/09/f2/Stubbins_Au stenitic%20ODS%20NEUP.pdf) • Synthesis and Characterization of Austenitic ODS alloys (http://www.mme.iitm.ac.in/murty/?q=node/96) 18 Literature Notes for Austenitic ODS Steel Composition • (http://energy.gov/sites/prod/files/2013/09/f2/Stubbins_Austenitic%20 ODS%20NEUP.pdf) 19 Preliminary Examination of 600-195-1400; Mt 14.046 • • SPACE SYSTEMS COMPANY Several Inconel 600 samples were metallographically cross-sectioned and polished Examination of microstructure on sample 600-195-1400 was conducted using backscattered electron imaging (BSE) Sample was not yet etched BSE images were taken in the three locations shown below Optical Image of Polished Cross-Section Sample 600-195-1400 Top Mid Bot Mt 14.046 8-7-14 JAB STAR Labs ~ 1cm 20