Mineral insulated cable inconel

advertisement

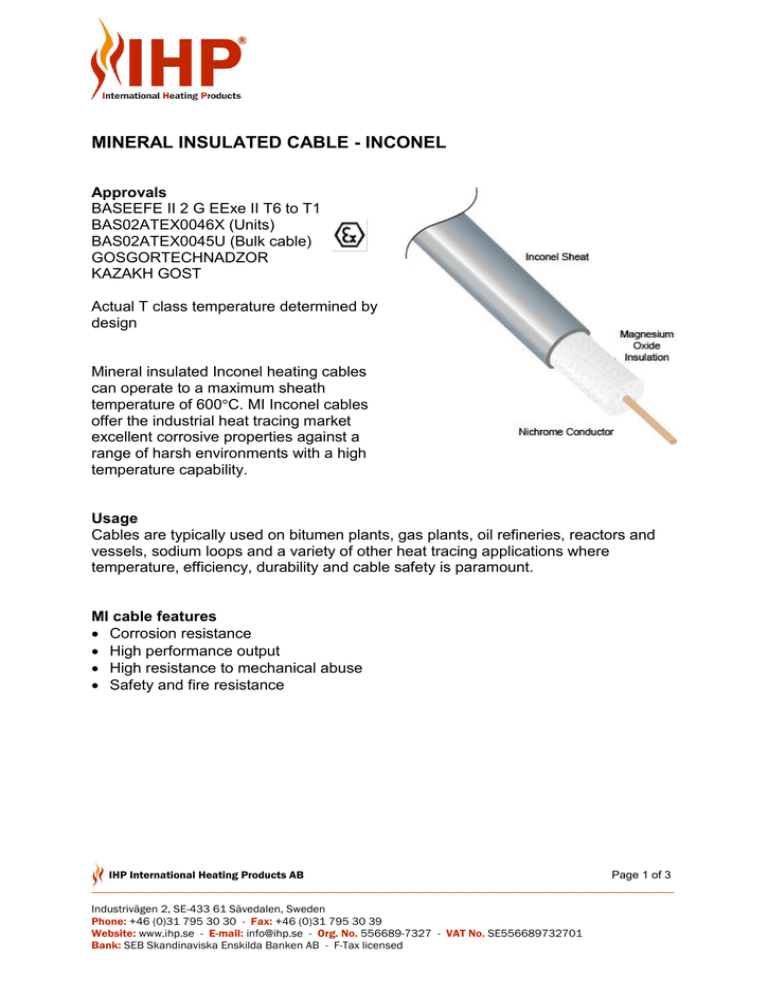

MINERAL INSULATED CABLE - INCONEL Approvals BASEEFE II 2 G EExe II T6 to T1 BAS02ATEX0046X (Units) BAS02ATEX0045U (Bulk cable) GOSGORTECHNADZOR KAZAKH GOST Actual T class temperature determined by design Mineral insulated Inconel heating cables can operate to a maximum sheath temperature of 600 C. MI Inconel cables offer the industrial heat tracing market excellent corrosive properties against a range of harsh environments with a high temperature capability. Usage Cables are typically used on bitumen plants, gas plants, oil refineries, reactors and vessels, sodium loops and a variety of other heat tracing applications where temperature, efficiency, durability and cable safety is paramount. MI cable features Corrosion resistance High performance output High resistance to mechanical abuse Safety and fire resistance IHP International Heating Products AB Page 1 of 3 _________________________________________________________________________________________________________________ Industrivägen 2, SE-433 61 Sävedalen, Sweden Phone: +46 (0)31 795 30 30 - Fax: +46 (0)31 795 30 39 Website: www.ihp.se - E-mail: info@ihp.se - Org. No. 556689-7327 - VAT No. SE556689732701 Bank: SEB Skandinaviska Enskilda Banken AB - F-Tax licensed Construction specification Cable sheat ....................................... Inconel 600 Cable insulation ................................. MgO (Magnesium Oxide) Cable conductor ................................ Nichrome Supply voltage ................................... Up to 300/500 VAC Withstand voltage .............................. 2.0 kV rsm ac Insulation resistance .......................... 1000 MΩ/1000 m (factory pass level) Max allowed sheath temp. .................600⁰C Earth leakage ....................................3mA/100 m (nominal at 20⁰C) Min installation temp. .........................-60⁰C Min bending radius ............................6 x OD (cable outside diameter) at -60⁰C Min cable spacing ..............................25 mm Area classification..............................Hazardous area, zone 1 and zone 2, ordinary Technical data Cable Conductor Conductor diameter diameter material (mm) (mm) HIQ1M10K 3.2 Nichrome 0.37 HIQ1M6300 Nichrome 3.2 0.47 HIQ1M4000 Nichrome 3.2 0.59 HIQ1M2500 Nichrome 3.4 0.74 HIQ1M1600 Nichrome 3.6 0.93 HIQ1M1000 Nichrome 3.9 1.17 HIQ1M630 Nichrome 4.3 1.48 HIQ1M400 Nichrome 4.7 1.85 HIQ1M250 Nichrome 5.3 2.35 HIQ1M160 Nichrome 6.5 2.93 Note: All resistances shown are nominal at 20°C Cable ref Resistance (Ω/km) 10000 6300 4000 2500 1600 1000 630 400 250 160 Nominal coil length(m) 772 774 776 689 617 528 437 368 292 194 Coil Approx diameter Weight (mm) (kg/km) 610 39 610 39 610 39 610 46 610 52 610 62 610 78 610 96 610 127 915 191 IHP International Heating Products AB Page 2 of 3 _________________________________________________________________________________________________________________ Industrivägen 2, SE-433 61 Sävedalen, Sweden Phone: +46 (0)31 795 30 30 - Fax: +46 (0)31 795 30 39 Website: www.ihp.se - E-mail: info@ihp.se - Org. No. 556689-7327 - VAT No. SE556689732701 Bank: SEB Skandinaviska Enskilda Banken AB - F-Tax licensed Maximum operating temperatures Rating factor table Cable ref. Rating factor HIQ1M10K 1.000 HIQ1M6300 1.000 HIQ1M4000 1.000 HIQ1M2500 0.952 HIQ1M1600 0.901 HIQ1M1000 0.840 HIQ1M630 0.769 HIQ1M400 0.714 HIQ1M250 HIQ1M160 0.645 0.538 Follow steps below to obtain sheath temperature guidelines from the graph for ordinary area applications. Step 1: By design, identify cable reference to be used and calculate watts/meter rating of cable/element e.g. HIQ1M1000, 100watt/m. Step 2: Refer to rating factor table and multiply watts/meter rating of cable/element by rating factor to obtain adjusted watts/meter value. (100W/m x 0.840 = 84W/m) Step 3: Using adjusted value, enter graph on watts/meter axis and obtain cable sheath temperature for application maintain temperature. Cable sheath temperature = 540⁰C for 400⁰C maintain- see graph. X GE GE A Chloride X Sea water A Alkalis X Organic Acid X Nitric Acid 600⁰C High nickel, high chromium content Inconel alloy 600 Phosphoric acid Description Hydrofluoric acid Alloy600 DIN 2.4816 Max. cable sheath temp. Hydrochloric acid Sheath material Sulphuric acid MI Heating cable sheath corrosion resistance and temperature data GE Note: GE = Good to excellent, A = Acceptable, NR = Not recommended, X = Check for specific data Corrosion resistance data is dependent on temperature and concentration. IHP International Heating Products AB Page 3 of 3 _________________________________________________________________________________________________________________ Industrivägen 2, SE-433 61 Sävedalen, Sweden Phone: +46 (0)31 795 30 30 - Fax: +46 (0)31 795 30 39 Website: www.ihp.se - E-mail: info@ihp.se - Org. No. 556689-7327 - VAT No. SE556689732701 Bank: SEB Skandinaviska Enskilda Banken AB - F-Tax licensed