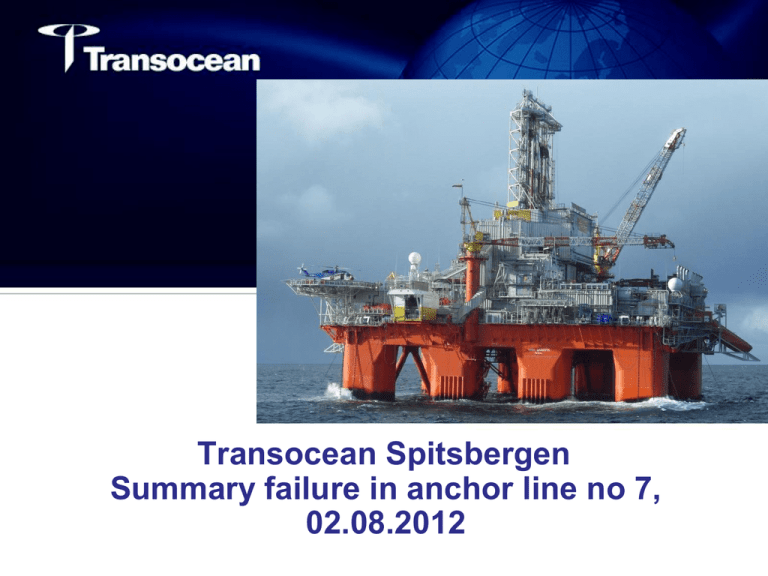

4-Transocean

advertisement

Transocean Spitsbergen Summary failure in anchor line no 7, 02.08.2012 Failure in anchor line 7, 02.08.2012 Broken link no 740 appr 10 m above fairlead 2 Findings from investigation report after the failure in anchor line 7 Anchorline 7 consisted of 4 x 500 m segments of 84 mm NV R4, studded anchor chain The inner segment, was produced as chain production no 241 in the period from 06.09.2007 to 08.09.2007 by Jiangsu Asian Star Anchor Chain Co., Ltd, China and certified by DNV, Certificate SHA-07-3409, issued 05.01.2008 Chain production no 241 consists of a total of 1487 links and the broken link no 740 is located close to the middle of this segment. 3 Findings from investigation report after the failure in anchor line 7 4 Arrangement of thermocouple of heat treatment Furnace no 3 5 Heat treatment parameter curve figure Furnace no 3 , ref MRB 6 5-link length checking record for mooring chain proof load test, ref MRB 7 Dimensioning checking record of mooring link , ref MRB 8 Findings from investigation report after the failure in anchor line 7 The failure was caused by corrosion fatigue exposed to high stress and propagated with fast overload fracture The underlaying cause was improper heat treatment resulting in hard material in a ”train” of 18 links It was identified corrolation between high hardness measured in the broken link and the surface hardness On this background, hardness measurements were initiated on each link (1009) in the broken chain segment and 20% in remaing segments of 8 anchor lines. No links with high hardness values were observed during the measurement performed by DNV 9 Summary after hardness measurements of all chain Transocean Spitsbergen. In segment that failed: 100% hardness measured by Brinell, 1009 links (336 m) Measured in both link ends Rest of chain: 20% hardness measured by Brinell, 8326 links (14154 m) Total measured 9335 links (14 490 m) No link with high hardness was observed All 8 anchorlines are certified for 5 years 10 ASAK testing heat treatment Furnace no 3 Test of 30 links, stopped in cooling water and run through tempering tower with max speed. 19 links were measured with higher hardness than recommended 352 HB 11