PowerPoint 演示文稿

advertisement

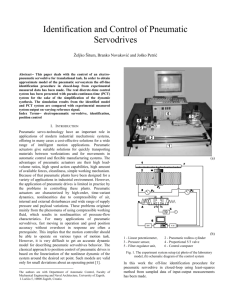

CHAPTER 11 PNEUMATICS TRANSMISION Objectives: The purpose of this chapter is to describe: 1. Advantages and disadvantages of pneumatic transmission 2. Operation and performance of various pneumatic elements. 3. Operation and performance of some usually used circuits. Upon completing this chapter, you should be able to: Be familiar with the main pneumatic components and standardized symbols used for their representation on circuit diagrams. Explain the operation principle and performance characteristics of some usually used circuits. Describe the function of each basic component in a practical pneumatic circuit Design a circuit to perform a desired function. CHAPTER 11 PNEUMATICS TRANSMISION 11.1 Pneumatics Overview 11.1.1 Pneumatic System Structure & Its Operation Principle In pneumatic system, compressors are used to compress and supply the necessary quantities of air that comes from the atmosphere. To operate and control these actuators, other pneumatic components are required i.e. air service units to prepare the compressed air and valves to control the pressure, flow and direction of movement of the actuators. Fig.11.1 A Basic Pneumatic System In production section: ①compressor, ②electric motor, ③pressure switch, ④check valve, ⑤tank, ⑥pressure gauge, ⑦auto drain, ⑧ safety valve, ⑨refrigerated air dryer, ⑩line filter In consumption section: ①air take-off, ②auto drain, ③air service unit, ④directional valve, ⑤actuator, ⑥speed controllers 11.1.2 Pneumatics Properties Table 11.1.Advantages of Pneumatics Availability Transport Storage Temperature Explosion proof Air is available practically everywhere in unlimited quantities. Air can be easily transported in pipelines, even over long distances. Compressed air can be stored in a reservoir and removed as required. Compressed air is relatively insensitive to temperature fluctuations. Compressed air offers no risk of explosion of fire. Components Unlubricated exhaust air is clean. Any unlubricated air that escapes through leaking pipes or components does not cause contamination. The operating components are of simple construction and therefore relatively inexpensive. Speed Compressed air is a very fast working medium. This enables high working speeds to be attained. Overload safe Pneumatic tools and operating components can be loaded to the point of stopping and are therefore overload safe. Cleanliness CHAPTER 11 PNEUMATICS TRANSMISION Table 11.2.Disdvantages of Pneumatics Preparation Compressed air requires good preparation. Dirt and condensate should not be present. Compression It is not always possible to achieve uniform and constant piston speeds with compressed air. Force requirement Compressed air is economical only up to a certain force requirement. Under the normal working pressure of 600 to 700 kPa (6 to 7 bar) and dependent on the travel and speed, the output limit is between 40000 and 50000 N. Noise level The exhaust air is loud. This problem has now, however been largely solved due to the development of sound absorption material and silencers. 11.2 Air Generation and Treatment Fig.11.2 Structure of Air Preparation System 11.2.1.2 Air generation equipments and preparation Fig.11.4 Two Stage Piston Compressor 11.2.1.2 Air generation equipments and preparation Fig.11.5 Rotary sliding vane compressor 11.2.1.2 Air generation equipments and preparation Fig.11.6 Screw Compressor 11.3 Actuators 11.3.1. Linear Cylinder Fig.11.15 Construction of a Cylinder 11.3.2 Rotary Actuators 11.3.3. Air Motors Air motors are similar in construction and function to hydraulic motors, and are most commonly of the rotary vane, gear, radial piston, or axial piston type. They can operate at speeds in excess of 10,000rpm. Air motors have several advantages that are important in some applications. One advantage is that air motors can stall under full load for indefinite periods of time, another is that they can be used in applications where electric motors would constitute a fire hazard. 11.4 Pneumatic Control Valves 11.4.1 Pressure Control Valves Fig.11.20 Safety Valve 11.4.3 Directional Control Valves Fig.11.38 Solenoid Valves 11.5 Basic Pneumatic Circuits Fig.11.50 Automatic Reciprocate