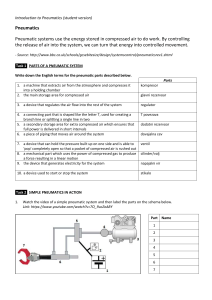

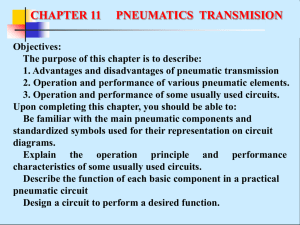

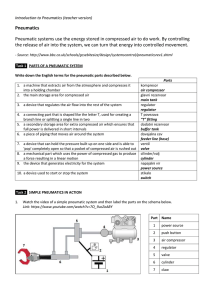

Introduction to Pneumatic Objective Appreciate the power of compressed as used in pneumatic ◼ Name applications of pneumatic ◼ Define pneumatic ◼ Solve problem applying Boyles law ◼ Enumerate safety practices ◼ Pneumatics - Use Some examples of everyday pneumatic systems are shown below. How many do you recognise? Pneumatics - Use Some examples of everyday pneumatic systems are shown below. How many do you recognise? In these industries, pneumatics are used to perform the following functions: • Replacing human force such as arms and fingers • Creating a very fast movement compared to human limbs • Creating a hygienic production scene • Detecting states by means of input elements (sensors) • Processing information using processing elements (processors) • Switching operating elements by means of control elements • Doing work using operating elements (drives) Pneumatics - Use Pneumatics are also used a lot in industry. It can be used to do lots of different jobs such as moving, holding or shaping objects. MOVE HOLD FORM PROCESS Overview ◼ Pneumatics play a major role in the automated work environment and are still gaining importance. ◼ Many production processes would be inconceivable without them. ◼ Pneumatics are an inherent part of almost every production system in the following industry sectors: ◼ Automotive: Overview ◼ Food and Packaging: ◼ Electronics: Overview ◼ Biotech and Pharma: ◼ Handling and Processing: Overview (Characteristics of Pneumatic) Advantages of Pneumatics Clean: Pneumatic systems are clean because they use compressed air. If a pneumatic system develops a leak, it will be air that escapes and not oil. This air will not drip or cause a mess which makes pneumatics suitable for food production lines. Safe: Pneumatic systems are very safe compared to other systems. We cannot, for example, use electronics for paint spraying because many electronic components produce sparks and this could cause the paint to catch fire. Advantages of Pneumatics Reliable: Pneumatic systems are very reliable and can keep working for a long time. Many companies invest in pneumatics because they know they will not have a lot of breakdowns and that the equipment will last for a long time. Economical: If we compare pneumatic systems to other systems, we find that they are cheaper to run. This is because the components last for a long time and because we are using compressed air. Advantages of Pneumatics Flexible: Once you have bought the basic components, you can set them up to carry out different tasks. Pneumatic systems are easy to install and they do not need to be insulated or protected like electronic systems. Definitions related to pneumatics ◼ ◼ Pneumatics is the blanket term for the physical science of compressing air, and for the branch of mechanical engineering that deals with the use of compressed air or gas. Force: Anything that causes an object with a mass to accelerate or decelerate . In pneumatics , this is the mass that the piston has to move or the perpendicular force that is applied to the tip of the piston rod . Definitions related to pneumatics ◼ ◼ Pressure: Is the force per unit area applied to an object , in pneumatics that is the pressure of the compressed air. Area: The area of an object where the force is applied, in pneumatics that is the area of the piston or the area of the piston without the area of the rod. Definitions related to pneumatics Pressure units ◼ The most common pressure units that can be read on manometers are: ◼ ◼ ◼ ◼ bar psi Mpa Boyles Law a relation concerning the compression and expansion of a gas at constant temperature. ◼ This empirical relation, formulated by the physicist Robert Boyle in 1662, states that the pressure (p) of a given quantity of gas varies inversely with its volume (v) at constant temperature; i.e., in equation form, pv = k, a constant. ◼ Boyles Law Boyle's law ◼ Demonstration of Boyle's law showing that for a given mass, at constant temperature, the pressure times the volume is a constant. ◼ The law can be derived from the kinetic theory of gases assuming a perfect (ideal) gas (see perfect gas). ◼ ◼ Boyle's gas law states that the volume of a gas is inversely proportional to the pressure of the gas when the temperature is held constant. This example problem uses Boyle's law to find the volume of gas when pressure changes. Boyle's Law Example Problem ◼ A balloon with a volume of 2.0 L is filled with a gas at 3 atmospheres. If the pressure is reduced to 0.5 atmospheres without a change in temperature, what would be the volume of the balloon? Solution ◼ Since the temperature doesn't change, Boyle's law can be used. Boyle's gas law can be expressed as: PiVi = PfVf ◼ Where: ◼ Pi = initial pressure ◼ Vi = initial volume ◼ Pf = final pressure ◼ Vf = final volume ◼ To find the final volume, solve the equation for Vf: ◼ Vf = PiVi/Pf ◼ Vi = 2.0 L ◼ Pi = 3 atm Pf = 0.5 atm Vf = (2.0 L) (3 atm) / (0.5 atm) Vf = 6 L / 0.5 atm Vf = 12 L Answer: The volume of the balloon will expand to 12 L. Safety Rules ➢ Never blow compressed air at anyone, not even yourself. ➢ Never let compressed air come into contact with your skin, as this can be very dangerous. ➢ Always wear safety goggles when you are connecting and operating circuits. ➢ Check that all airlines are connected before turning on the main air supply. Safety Rules ➢ Always turn off the main air supply before changing a circuit. ➢ Keep your hands away from moving parts. ➢ Avoid having airlines trailing across the floor or where someone could trip or become entangled. Exercises: ➢ Give three examples of the everyday use of pneumatics. ➢ Choose one of your examples from question 1. Draw a system diagram and describe how it makes use of compressed air. ➢ What is compressed air? ➢ Give two reasons why pneumatic systems are used in industry. ➢ A gas occupies 11.2 liters at 0.860 atm. What is the pressure if the volume becomes 15.0 L? ➢ 500.0 mL of a gas is collected at 745.0 mmHg. What will the volume be at standard pressure?