Adaptive backstepping

advertisement

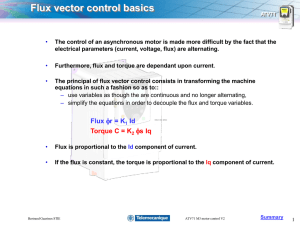

Robust and Efficient Control of an Induction Machine for an Electric Vehicle Arbin Ebrahim and Dr. Gregory Murphy University of Alabama Outline Project Objectives What is Adaptive Control? Definition of Adaptive Backstepping Advantages of Using a Adaptive Backstepping Controller Problem Formulation Design Procedures Project Work Summary Project Objectives Robust and efficient control of an induction motor for an electric vehicle Track the speed of an induction motor to a desired reference trajectory under timevarying load torque for an electric vehicle Robust control of an electric vehicle induction motor under varying changes in the motor parameters. What is an Adaptive Controller? Learning Mechanisms (Parameter Adaptation) Coordination Mechanisms Robust Feedback r (t) Adjustable Model Compensation u x Plant To invent, design and build systems capable of controlling unknown plants or adapting to unpredictable changes in the environment y What is Backstepping? x= f x + =u u ∫ V = 1 x2 2 δ des = x , V ≤ 0 z = - des Va = 1 x 2 + 1 z 2 2 2 u = c x , V a ≤ 0 V,Va = Lyapunov Functions x, = State Variables z = Virtual State (x) = Virtual Control u = plant input ∫ x f (x) u - ∫ z ∫ x f ' (x) Backstepping is to design a controller for a system recursively by considering some of the state variables as “Virtual Controls” and designing for them intermediate control laws Advantages of Adaptive Backstepping Controller Design Procedure Both the stability properties and control law can be ensured in this same step The Control Law can be obtained in steps no greater than the order of the system In adaptive backstepping unknown plant parameters can be easily dealt with to design control laws Observers can be easily incorporated in the design procedure to perform observer backstepping Problem Formulation Flux Command r +- ids Vds * Vds Flux Controller ref iqs ref * Vqs Speed Controller +Speed Command * r * Rotating Stator Frame to Stationary Stator Frame Conversion cos Va Space Vector Modulation Vqs sin ia ib ic Flux Estimator Where ids iqs * = Flux component of the Stator Current * = Speed component of the Stator Current * Vds , Vqs *= Voltages in the rotating stator frame r = Measured Speed of the Motor r = Estimated Flux of the motor i a , ib , ic = Measured Stator Currents Va , Vb , Vc = Applied three phase stator voltages Power Stage Vc r 3 Vb r IM Time varying Load Torque Design Procedure Modeling-: The equations representing the dynamics of motion of the Induction Motor is derived in the three phase, stationary and rotating stator frame co-ordinates and analyzed for the application of Adaptive Backstepping procedure. Controller Design-: Flux Controller-: An Observer Backstepping Flux Controller is designed using flux observers to make the estimated flux track a desired reference trajectory to ensure that sufficient torque is delivered to Load Speed Controller-: An Adaptive Backstepping Speed Controller is designed to make the measured speed of the motor track a desired reference trajectory under varying Load Torque Conditions Simulation-: The adaptive controllers designed are simulated in the Simulink environment to verify the results Design Procedure……………………Continued Hardware Implementation-: The Adaptive Controllers developed are verified in real time using an Induction Motor tied to a varying load. The results are observed and conclusions made Project Work Summary Model the Induction Motor in the stationary and rotating stator frames so that Vector Control can be applied to develop a speed controller as well as a flux contoller Apply adaptive backstepping procedure to develop a speed controller for the motor speed to track a desired reference speed under time varying load conditions Design flux observers to estimate the flux and design an observer based backstepping controller for the flux to track a desired reference trajectory so that sufficient torque can be supplied to the Load Develop a modular design in Simulink environment for the motor models, observer models, controller models, and etc for simulation Implement real-time controller application to an Induction Motor for verifying and comparing the simulation results to the real-time results; to make conclusions and recommendations on future research