The development of floors

advertisement

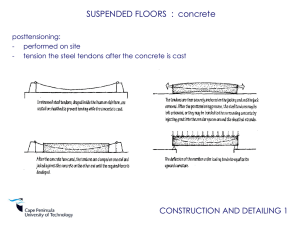

After the foundations have been completed and the external walls constructed the construction of the floors commences. There are many methods of construction which have developed over the last century. The following slides feature some of these. The development of floors Bare earth or stone cobbles • The earliest methods of floor construction was a bare earthen floor. The earth was compacted and gradually dried out after a period of time. • If the floor was to receive continual wear it may have been cobbled. Cobbles are small stones which are placed over the floor in such a fashion that they form a continuous solid surface. Timber floors • Suspended timber floor joists are supported by the walls which transfer the load from the floor, through the wall to the foundations. • The traditional method of providing a flooring surface on top of these joist’s was sawn timber boards which had square edges. These boards were butted together and nailed down unto the top of the joist. • The quality of the flooring boards was improved by the addition of tongue and grooved joints. Supporting wall Floor joist Square edge flooring 150mm wide and 20mm thick. Supporting wall Timber ground floors • • If timber ground floors are used ventilation must be provided beneath the floor construction. The reason for this ventilation is to prevent the moisture content of the timber rising above an unacceptable level (ie. 20%) which would create the conditions for possible fungal attack. Joist spaced at 400mm centres. Plywood sheeting Sheet materials such as plywood and chipboard are now the most popular coverings to floor joists. The most common size of sheets are 1220mm x 2440mm. • Floor joists are usually placed at 400mm centres. Positions for ventilation Suspended T beam concrete floor Concrete blocks laid between T beams Pre-stressed concrete floor beams 100mm sand and cement screed on top of beam floor Pre-stressed T beam concrete floors were one of the first methods of creating suspended concrete floors. The beams were set in position in such a way that a 450mm concrete block fitted neatly between the beams. The load of the floor was transferred to the foundations by the beams. Pre-stressed concrete floor beams cast in the shape of an inverted T Solid concrete floors • This is the most common type of ground floor in use today where the depth of hardcore fill underneath the floor does not exceed 1200mm deep. • The main requirements of any floor are to provide a level surface which is resistant to heat loss. A solid floor must also provide resistance to the passage of moisture from the ground. • Insulation is incorporated into the floor to prevent the loss of heat into the ground underneath the floor. • Service pipes may also be accommodated in the floor screed. 100mm deep sand and cement screed Insulation 100mm deep concrete sub floor Damp-proof membrane (DPM) Hardcore fill Suspended concrete floors • • • • HomeSPAN is the trade name for a suspended concrete flooring system which has recently been developed for the domestic market. This flooring system comprises of flat precast concrete planks generally 600mm wide and 150mm deep. It can carry domestic loadings up to 5m clear span. These concrete floors have excellent sound insulation and fire resistance. After settlement, cracking is dramatically reduced as most cracks results from the shrinkage of timber joist. Suspended concrete flooring slabs. Walls constructed to support floor slabs.