Important Terms and Objective of Process Control Systems(过程

advertisement

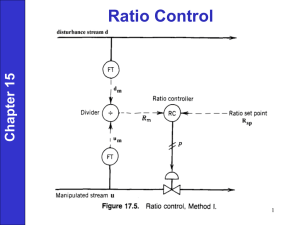

Process Control Engineering Institute of Industrial Control, Zhejiang University 2013/06/26 考核说明 考核:平时成绩 50%,包括课堂提问、 平时练习、综合练习;期末考试(闭 卷)50% 课堂提问 平时练习 满分20分。缺课1次扣5分。 满分10分。平时作业的平均分 综合练习 20分 概论 Origin of Process Control Systems(过程控制 系统的由来) Important Terms and Objective of Process Control Systems(过程控制的术语与目标) Description of Process Control Systems(过程 控制系统的描述) Types of Control Strategies (控制策略分类) Course Tasks(课程任务) Feedback Control Process (反馈控制过程) 1. Measure the level by a sensor (传感器) and convert the output from the sensor to an electric signal by a transmitter (变送器) 2. The controller(控制器/调节器) then receives the signal and compares it with the value desired; 3. Depending on this comparison, the Qi controller decides what to do to correct for any deviation; 4. Based on this decision, it sends a signal to the final control element( 执行单元), e. g., a control valve and change the controller process. hsp h LT 21 Qo LC 21 Important Terms (重要术语) of Automatic Process Control Controlled Variable (CV, 被控变量/受控变量) The variable that must be maintained or controlled at some desired value. Setpoint (SP,设定值/给定值) The desired value of the controlled variable. Controller Output (OP, 控制器输出) Manipulated Variable (MV,操纵变量/操作变量) The variable used to maintain the controlled variable at its setpoint. Disturbance (DV,扰动/扰动变量) Any variable that causes the controlled variable to deviate away from its setpoint. Control Diagram Psp Pm PC 51 PT 51 u F1 P2 f2 P P1 f1 F2 Variable relations are as follows: dP V K1 F1 K 2 F2 dt F1 KV 1 f1 P1 P f1 100 u For the above pressure control system, please describe its CV, SP, F2 KV 2 f 2 P P2 OP, MV, DVs, control diagram as well as control objective. P2 Controlled by a single loop? Psp + PC 51 _ u(t) Control Valve P1 P2 f2 Disturbance Path (干扰通道) f1 Control Path (控制通道) + + Controlled Process Pm PT 51 P(t) Process Characteristics Importance of Process Characteristics (过程 对象特性的重要性) Introduction of Final Control Elements (执行 机构介绍) Types of Processes (过程特性分类) Obtaining Characteristics from Process Dynamics (过程特性机理建模法) Obtaining Characteristics from Process Data (过程特性测试建模法) Summary Heat Exchanger Temperature Control System Tsp Steam u(t) TC 22 Tm The extended controlled process (广义对象) is anything except the controller. RV TT 22 RF , Ti Process Fluid T Condensate Tsp u(t) Controller I/P & valve Heat exchanger Sensor Transmitter mA, CO Tm(t) mA, TO Flow T mV Types of Processes Self-regulating processes (or stable processes, 自衡过程/稳定对象) (1) Single-Capacitance Processes (2) Multi-Capacitance Processes Non-self-regulating processes (or unstable processes,非自衡过程) Ex.: some level processes and some reactors Terms that Describe the Process Characteristics Process Gain (K) Ratio of the change in output (or responding variable) to the change in input (or forcing function). Output O final Oinitial K Input I final Iinitial Process Time Constant (T) Process Dead Time (τ) Notes to Process Gain Process gain describes the sensitivity of the output variable to a change in input variable. Process gain includes three parts: Sign, Numerical value and Units. Process gain relates only steady-state values, so the gain is a steady-state characteristic of the process. Obtain the Dynamic Terms from the Step Response Curve Controller Output 65 % 60 T 1.5 t0.632 O t0.283 O 55 ? 50 45 0 10 20 30 40 50 Heat Exchanger Outlet Temp. 160 t0.632 O T0 T 158 63.2% Cent 156 154 ? 28.3% 152 150 148 T2 T0 0 10 T1 20 30 time, min 40 50 PID Controller Selection of Valve Action (调节阀作用选择) Action of Feedback Controllers (反馈控制器 的正反作用) Performance Criterion of Process Control Systems (过程控制系统的性能指标) Understand P, PI and PID Controllers Problem Discussion Types of Control Valves pc ....... ....... ....... ....... Fail-opened Valve (气关阀) pc Fail-closed Valve (气开阀) Action of Controllers Direct Action (正作用) when the signal from the transmitter increases, the controller output also increases. Reverse Action (反作用) when the signal from the transmitter increases, the controller output decreases on the contrary. Note: The set point is not part of decision. Selection of Controller Action Controlled Plant D (t) ysp u(t) Final Control e(t) + ym(t) Controller Element _ MV Disturbance Path Control Path + Sensor & Transmitter Principle: to construct a negative feedback loop ? + y(t) Controller action selection based on loop analysis Ex. 1 Tsp TC 22 u(t) Steam Step 1: plot block diagram RV Step 2: indicate the action direction for each block except the controller. Tm TT 22 Heat Exchanger RF , Ti Process Fluid T Step 3: determine the action of the controller to construct a negative feedback loop Condensate TC 22 must be reverse D (t) (+) Tsp e(t) + u(t) TC 22 _ (+) Steam Valve (+) Tm TT 22 RV Heat Exchanger (+) T PID Controller: Effect of P on Control Performances P controllers have only one tuning parameter, Kc. However, they suffer a major disadvantage – there exists an Offset of the controlled variable from the set point. (Why ?) For a given step disturbance, the magnitude of the offset depends on the value of the gain. The larger the gain, the smaller the offset. Above a certain Kc, most processes go unstable. Effect of Integral Action on Control Performances PI controllers have two tuning parameter: the gain or proportional band, and the integral time or the integral rate (1/Ti ). The advantage is that the integration removes the offset. (Why ?) The disadvantage of PI controllers is that the addition of integration adds some amount of instability to the system. The smaller the integral time, the stronger the integral action, the faster the system removes the offset, but the weaker the stability of the system. Effect of Derivative Action on Control Performances PID controllers have three tuning parameter: the gain, the integral time and the derivative time. The derivative action gives the controller the capability to anticipate. PID controllers are recommended for use in slow processes with long time constants, such as temperature loops, which are usually free of noises. For fast processes with noises, such as flow loops and pressure loops, the use of derivative action will amplify the noise and therefore should not be used. PID Tuning Selection of PID Controller Types (PID控制 器类型选择) Tuning of PID Controller Parameters (控制 器参数整定) Flow Control (流量控制) Level Control (液位控制) Reset Windup and Its Prevention (积分饱和 与防止) Summary Obtain Initial PID Para. (Ziegler-Nichols Method) Controller Kc P 1 T K PI PID 0.9 T K 1.2 T K Ti Td 3.33 2.0 0.5 Note: the above method was developed for 0 T Obtain Initial PID Para. (Lambda Tuning Method) Controller Kc P 1 T K 1 T K PI PID 1 T K Ti Td Initial Value 0 T T τ/2 0.2 Note: the above method is not limited by the value of / T Digital PID Concept of Digital Control Systems Selection of Digital Filters Digital PID Controllers and Its Improved Version Concept of Distributed Control Systems Summary Digital PID Positional Algorithm Ideal analog PID algorithm 1 u (t ) Kc e(t ) Ti t 0 de(t ) 0 e( )d Td dt u0 , e(t ) ysp (t ) y(t ) t k e( )d Ts e( j ) j 0 d e(t ) e(k ) e(k 1) dt Ts Digital PID positional algorithm (位置算法) Ts u (k ) Kc e(k ) Ti Td e( j ) e(k ) e(k 1) u0 Ts j 0 k Digital PID Incremental Algorithm Digital PID positional algorithm Ts u (k ) Kc e(k ) Ti Td e( j ) e(k ) e(k 1) u0 Ts j 0 k Digital PID incremental algorithm(增量算法) u (k ) u (k ) u (k 1) Ts Td K c e(k ) e(k 1) e(k ) e(k ) 2e(k 1) e(k 2) , Ti Ts u (k ) u (k 1) u (k ) PID incremental algorithm with derivative action first Digital PID incremental algorithm Ts Td u (k ) K c e(k ) e(k 1) e(k ) e(k ) 2e(k 1) e(k 2) Ti Ts Digital PID incremental algorithm with derivative action first (微分先行PID增量算法) T T u (k ) K c e(k ) e(k 1) s e(k ) d y f (k ) 2 y f (k 1) y f (k 2) , Ti Ts u (k ) u (k 1) u (k ) Cascade Control Concept of Cascade Control(串级控制概念) Characteristics of Cascade Control(串级控制 系统的特性分析) Design Principle of Cascade Control (串级控 制的设计原理) Implementation and Tuning of Controllers (串级控制器的实现与参数整定) Simulation Examples(仿真举例) Process Example: A Cascade Control Scheme TC 23 Tsp Tm (1) This scheme consists of two sensors, two transmitters, two controllers, and one valve. Fsp Fm FC 13 u(t) FT 13 TT 23 Ti (t) T Process Fluid Fgas Fuel Gas Please plot block diagram of the system ? (2) This scheme results in two control loops, one loop controlling T and the other loop controlling Fgas. Note: The flow of fuel gas is used only as an intermediate variable to improve control performance. Cascade Control Diagram for Outlet Temp. of Process Fluid D2 Tsp + - Tm TC 23 Fsp + - Fm FC 13 Control Valve Fuel Supply Subsystem D1 T Furnace Fgas FT 13 TT 23 where TC 23 is called “primary/master controller (主控制 器)”, and FC 13 is called “secondary/slave controller (副控 制器)”; D1 denotes disturbances entering the outer loop, D2 denotes disturbances entering the inner loop. General Cascade Control Diagram D2 D1 Secondary / Slave / Inner Loop y1,sp + - y2,sp Gc1 + - Gc2 ym2 Gv Gm2 ym1 Gp2 + + y2 Gp1 + + y1 Primary / Master / Outer Loop Gm1 Note: D1 denotes the effect of primary disturbances on primary CV, D2 denotes the effect of secondary disturbances. “Primary Loop” presents the outer loop where the inner loop is closed and set in remote set point or cascade mode. Design Principles of Cascade Control Systems The secondary variable must respond faster to changes in some disturbances than the primary variable does — the faster, the better Secondary loop or inner loop must include some obvious disturbances to primary variable— the more the better If possible, secondary loop should include some nonlinear plant Typical cascaded loops: temp. to flow, concentration to flow, pressure to flow, level to flow, temp. to pressure, temp. to temp. Cascade Control Examples of Heat Exchanger Fsp PV FC 17 Fm FT 17 Psp Steam RV Tsp TC 27 PV PC 37 Tm Pm TT 27 Ti TC 27 PT 37 RV Condensate Condensate Psp PV PC 37 Pm PT 37 Steam RV TC 27 Tsp TT 27 Ti Scheme #2 T Process Fluid Condensate T Process Fluid Tm TT 27 Tsp Tm Ti T Process Fluid Scheme #1 Steam Scheme #3 Feedforward Control Feedforward Concept Design of Linear Feedforward Controllers Design Examples of Feedforward Control Feedforward-Feedback Control Simulation Results Summary Design of Linear Feedforward Controllers (cont.) D (t) Disturbance Path GYD (s) Disturbance Measurement GDM (s) Dm (t) Feedforward Controller GFF (s) u(t) + Control Path GYC (s) + ym (t) Extended Controlled Process Design Objective: Ym ( s) GYD ( s) GYC ( s)GFF ( s)GDM ( s) D( s ) 0 Design formula for the feedforward controller: GYD ( s) GFF ( s) GYC ( s)GDM ( s) Design of Linear Feedforward Controllers (cont.) Design formula for the feedforward controller: GYD ( s) GFF ( s) GYC ( s)GDM ( s) GDM (s) K DM KYD GYD ( s) exp D s TYD s 1 GFF ( s) K FF K FF KYD KYC K DM KYC GYC ( s) exp C s TYC s 1 TYC s 1 exp FF s TYD s 1 FF max0, D C ( Why ? ) Feedforward / Feedback Control ysp Feedforward control system + + ∑ Feedforward control system u(t) Process y(t) D(t) ysp Comparison of Feedforward and Feedback Control Feedforward Control Feedback Control Disturbances are measurable CV is measurable Control MV based on disturbances Control MV based on control ERROR Open-loop, No Stability Problem Closed-loop, Stability is the most important Only some disturbances are detected All disturbances are detected Accurate model needed for both of Control and Disturbance Paths No accurate model needed Not adaptable to nonlinear or time-varied systems Adaptable to nonlinear or timevaried systems Ratio Control Concept of Ratio Control Design of Ratio Control Schemes Cross-limiting Control of Air/Fuel Ratio in a Boiler or Furnace Summary Ratio Control QB IB K1 IA Suppose both of the flow transmitters are linear. Sometimes, they are nonlinear Steady-state condition: I A I 0 K1 ( I B 4) 4 mA FC Q QA QB K1 , K AB A QA max QB max QB QA QB max K1 K AB QA max Air/Fuel Ratio in a Boiler Control Scheme Steam ASP PT 22 AT 25 P PC 22 %O2 AC 25 PSP Stack PC22.OP LS HS FC23.SP FC23.PV RF FC 23 FC24.SP FC 24 × FC24.PV Cross-limiting control with O2 trim RA FT 23 Fuel KFA FT 24 FC FO Air (带有O2调节的双 交叉控制) Override and Selective Override/Constraint Control Problem Design of Constrain Control Systems Reset Windup and Its Prevention in Constrain Control Selective Control Schemes Override Control Scheme Feed liquid LS: Low Selector(低选器) u(t) = min(u1, u2) hmin LT 23 h1 LC 23 u2(t) SW Fsp u1(t) FC LS (+) u(t) 12 Fm (- ) FT 12 F(t) hmin FC Valve To process Smooth Switch problem between two loops ? Override Control Scheme Feed liquid LS: Low Selector(低选器) u(t) = min(u1, u2) LT 23 h1 hmin LC u2(t) 23 RFB Fsp LS u1(t) FC 12 Fm RFB FT 12 u(t) hmin F(t) To process RFB: (external) reset feedback(外部积分反馈) Reset Windup Prevention in Constraint Control hm 1 Ti 2 s 1 LC 23 - + KC2 u 2 v2 + u2 RFB + hmin LS u Fsp + - Fm KC1 u1 u1 RFB + + FC 12 1 Ti1 s 1 v1 Discuss: ONLY the controller in closed-loop condition has integral action, and the output of inactive controller will follow the output of active controller. Selective Control Example Feed Coolant TSP Tm1 Tm2 Tm TC HS Tm3 Tm4 Coolant Reactor Product Parallel Positioning Control Concept of Parallel Positioning Control (分程控制) Application of Parallel Valve-Positioning Control --- Batch Reactor Control Concept & Application of Valve Position Control Combination of Parallel Valves FC “ FC f (%) B” “ “ A” FC f (%) ” A “ O F B” 100 100 0 0 0.02 0.06 0.02 0.10 0.06 MPa MPa 100 “ f (%) FO B” A” “ B” “ O F ” A “ O F FC 100 f (%) 0.10 0 0 0.02 0.06 MPa 0.10 0.02 0.06 MPa 0.10 Parallel Valve Positioning Control Scheme #1 Tsp 100 Heated Water FC B” “ f (%) FO 电/气 转换器 TT 34 T I/P ” Tm A “ TC 34 u 0 Coolant Water Y “A” “B” Steam Analyze the whole control process 0.02 0.06 0.10 MPa Problem: (1) Choose the FO or FC type of control valves; (2) Plot the diagram; (3) Determine the controller action Methods for Compensating Process Nonlinearity Nonlinear Valves Cascade Control Variable Ratio Control Nonlinear Gain Compensation Nonlinear Transformation Identification + Adaptive Control Dead Time - Smith Predictor D (s) R (s) U (s) Gc(s) + _ + + + K p g p ( s )e K m g m ( s )e m s K m g m (s ) Y (s) p s _ + + Gf(s) 1 Prediction Error Filter:G f (s) Tf s 1 Coupling Analysis of Multivariable Systems (多变量系统的关联分析) Computation of Relative Gain for n×n Systems y u yi K ij u j ij yi u j yi u j u y, 1 H ji ue 0 ue 0 ye 0 K ij H ji , u j yi ye 0 yi 1 u j ye 0 T ij Note: “●” means the multiplication of matrix elements K non-invertible? Decoupling Control Schemes of Multivariable Systems (多变量系统的解耦控制) Block Diagram for a General 2*2 System with Decoupler #1 y1, sp y2, sp v1 Gc1(s) Gc2(s) u1 D11(s) v2 G11(s) D21(s) G21(s) D12(s) G12(s) D22(s) u2 G22(s) Decoupling Conditions ? y1m y2m Decoupler #1 for a General 2*2 System y1m ( s) G11 G12 D11 y2 m ( s) G21 G22 D21 y2 m 0, v1 D12 v1 ( s) D22 v2 ( s) y1m 0 v2 G11D12 G12 D22 0, G21D11 G22 D21 0 If D11 1, D22 1 G12 G21 D12 , D21 G11 G22 About Decoupler #1 y1, sp y2, sp u1 v1 Gc1(s) Gc2(s) G21 ( s ) G22 ( s ) G21(s) G12 ( s ) G11 ( s ) G12(s) v2 G11(s) G22(s) y1m y2m u2 Problem: (1) initial MVs’ value; (2) “Man/Auto” mode switch; (3) limit of MVs. Block Diagram for a 2*2 System with Feedforward Decoupler Man1 y1,sp y2,sp GC1(s) GC2(s) M v1 G11(s) A D21(s) G21(s) D12(s) G12(s) A G22(s) v2 M Decoupler u1 Man2 u2 y1m y2m Boiler Process Diagram and Control Problems of Boiler (锅炉设备的生产流程与控制问题) Characteristic Analysis & Three-element Control for Drum Level (汽包水位特性分析与 三冲量控制) Cross-limiting Air/Fuel Ratio Combustion Control (双交叉空燃比燃烧控制) Two-element (双冲量) Control D(t) Steam FT 02 Drum Hsp H(t) LT 11 Hm IV LC 11 IL ∑ u = C0+C1IL+C2IV F(t) Feedwater Problem discussion: (1) Point out the kind of control methods ? (2) Obtain control diagram of the scheme. (3) Select the controller action, the symbol and the value of C2, if the valve is a fail-open valve and C1=1. Distillation Distillation Principle & Control Problems Column Pressure Control Material Balance (物料平衡) Control Product Purity Control (1) Distillate Purity Control (2) Bottom Purity Control (3) Both Distillate & Bottom Purity Control Other Control Schemes