Document

advertisement

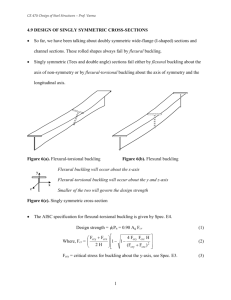

Lecture #4 Buckling in aircraft structures PLATES IN UNI-AXIAL COMPRESSION Object Buckling factor k 0.9 kE cr 2 b 2 PLATES IN SHEAR Object kE cr 2 b Buckling factor k 3 CYLINDRICAL RODS IN COMPRESSION Object Buckling factor k 0.3 kEh cr R k 0.25 0.2 0.15 0.1 analytically k=0.6! 0.05 R/h 0 0 500 1000 1500 4 SHPERICAL SHELL UNDER EXTERNAL PRESSURE Object Buckling factor k 0.2 k kEh cr R 0.15 0.1 0.05 R/h 0 0 500 1000 1500 analytically k=0.6! 5 FACTORS WHICH AFFECT THE ACCURACY OF BUCKLING ANALYSIS • Initial imperfections (the effect is especially large for cylindrical and spherical shells); • Curved geometry (very actual for aircraft panels); • Uncertain supporting conditions; • Inelastic behavior of material (the effect is crucial for lightweight and high-loaded aircraft structures). Ways to increase the accuracy of calculations: • Use empirical methods and formulas (much testing required); • Use numerical methods. 6 COMPARISON BETWEEN CIRCULAR AND SQUARE CROSS SECTIONS 7 WAYS TO FIND THE CRITICAL STRESS WHICH IS BEYOND THE YEILD LIMIT • Empirical determination of critical stress (Southwell method). • Usage of plasticity correction factors calculated by empirical formulas. • Finite element analysis (FEA). 8 SOUTHWELL METHOD FOR PLATES The deformed shape of panel is m x n y w x , y Amn sin sin a b m 1 n 1 C mn N x The view of coefficients is Amn f m, n N x Near the buckling mode corresponding Cmn N x to m and n, the displacement is wmax N x cr N x Thus, the graph of wmax against straight line with a slope of wmax N x cr . will form a Nx 9 PLASTICITY CORRECTION – EMPIRICAL FORMULAS Kan and Sverdlov proposed the following formula to take into account the plastic behavior of material: 1 cr u 2 1 where u cr , el , ; cr , el - elastic critical stress (calculated using linear physical law); u - material ultimate stress. 10 PLASTICITY CORRECTION – EMPIRICAL FORMULAS According to Gerard, the nonlinear material behavior could be taken into account using the plasticity correction factor h: 0.9 h k E cr 2 b 1 E s 1 1 1 3 Et h 1 E 2 2 4 4 Es Et , E s - tangent and secant moduli; el , pl - elastic and inelastic Poisson’s ratios. 2 el 2 pl 11 BUCKLING MODES OF AIRCRAFT PANEL 12 POST-BUCKLING BEHAVIOR The post-buckling behavior of aircraft panels is usually studied using the concept of “attached skin” having the width of 2c: 2c str cr , skin 2c t str cr , skin t 13 FLOWCHART OF NONLINEAR BUCKLING FEA Linear compression Linear buckling Transfer of initial imperfections Nonlinear analysis Linear physical law is used Probable modes of buckling are found, dangerous one is chosen depending on the area of interest The model is slightly modified according to buckling mode, nonlinearities are specified The critical force corresponds to the loss of convergence Results 14 FLOWCHART OF NONLINEAR BUCKLING FEA Dimensions of the panel: a = 60 mm, h = 22 mm, 1 = 4 mm, 2 = 6 mm. Length is 300 mm. Supporting conditions: clamped at all sides. Problem is to find a critical stress for this panel. 15 FLOWCHART OF NONLINEAR BUCKLING FEA Linear compression 16 FLOWCHART OF NONLINEAR BUCKLING FEA Linear buckling 1st mode 884 MPa 17 FLOWCHART OF NONLINEAR BUCKLING FEA Linear buckling 2nd mode 996 MPa 18 FLOWCHART OF NONLINEAR BUCKLING FEA Linear buckling 3rd mode 1210 MPa 19 FLOWCHART OF NONLINEAR BUCKLING FEA Transfer of initial imperfections 1) Rename *.rst file to "buckling.rst“, move it from buckling to structural analysis directory. 2) Insert a command object in the environment: /prep7 upgeom,0.1,1,1,buckling,rst /solu 3) Set nonlinearities: large deflection -> on nonlinear effects -> yes 20 FLOWCHART OF NONLINEAR BUCKLING FEA Nonlinear analysis 485 MPa – last substep converged 21 FLOWCHART OF NONLINEAR BUCKLING FEA Results 35 30 Shortening, mm 25 Nonlinear FEA predicted 509 MPa which is 1.73 times smaller than elastic solution. 20 15 10 5 Stress, MPa 0 0 100 200 300 400 500 600 22 EFFECT OF BUCKLING ON A STRUCTURAL LAYOUT Structural layout dimension Determinative factor Distance between ribs and fuselage frames Primary buckling of panels Distance between stringers Local buckling of skin between stringers Distance between spar web Buckling of spar web under stiffeners shear loads Distance between rivets in longitudinal joints Local buckling of skin between rivets 23 EFFECT OF BUCKLING ON A STRUCTURAL LAYOUT The stringer cross section is dramatically affected by buckling, showing the compromise between buckling resistance and technological simplicity: 24 WHERE TO FIND MORE INFORMATION? Megson. An Introduction to Aircraft Structural Analysis. 2010 Chapter 9 … Internet is boundless … 25 TOPIC OF THE NEXT LECTURE The concept of thin-walled beam. Normal stresses All materials of our course are available at department website k102.khai.edu 1. Go to the page “Библиотека” 2. Press “Structural Mechanics (lecturer Vakulenko S.V.)” 26