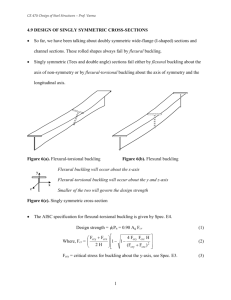

Document

advertisement

LINEAR BUCKLING ANALYSIS 1 MECHANISM OF BUCKLING Buckling refers to sudden large displacements due to compressive loads. Slender structures subject to axial loads can fail due to buckling at load levels lower than those required to cause material failure. Buckling can occur in different modes under the effect of different load levels. In most cases, only the lowest buckling load is of interest. To grasp the concept of buckling, note that any structural load affects structural stiffness. Tensile loads induce a positive stress stiffness which gets added to the elastic stiffness of the structure (also called shape stiffness). A compressive load induces a negative stress stiffness which gets subtracted from the elastic stiffness of the structure. Buckling takes place when, as a result of subtracting the stress stiffness induced by compressive load from elastic stiffness, the resultant structures stiffness drops to zero. This is analogous to modal analysis where the inertial stiffness is subtracted from the elastic stiffness also producing a zero resultant stiffness. 2 MECHANISM OF BUCKLING The cancellation of resultant stiffness can be described by equation: Eigenvalue multiplied by the applied load gives the critical loading The first mode and its associated magnitude of buckling force is the most important because buckling most often causes catastrophic failure or renders the structure unusable even if the structure can still withstand the load in its buckled shape. 3 LINEAR VS. NONLINEAR BUCKLING Buckling can be thought of as a situation where a very small increase in the load causes very large displacements. Buckling analysis, which is more precisely called linear buckling analysis, calculates that load, called buckling load, and the shape assumed under the buckling load. However, linear buckling analysis, does not offer any quantitative information on the deformed post-buckling shape. Linear buckling analysis just finds the eigenvalues of structure for given loads and restraints disregarding any imperfections and nonlinear effects which always exist in real structures. Those imperfections and non-linear effects very significantly lower the buckling loads as compared to those predicted by linear buckling analysis. For this reason, the results of linear buckling analysis must be interpreted with caution remembering that real buckling load may be very significantly lower than that predicted by linear buckling analysis. Nonlinear buckling analysis must be used to find accurate values of buckling load as well as to study post-bucking effects. Some buckling problems that always require nonlinear buckling analysis and can not even be approximated by linear buckling analysis include: inelastic or nonlinear material behavior prior to instability, re-alignment of applied pressure during displacement or finite displacements prior to buckling. Buckling should always be considered as potential mode of failure in structure consists of slender members in compression. In fact many structural disasters are initiated by buckling and only the final destruction is caused by excessive stresses in post buckling stage. 4 BUCKLING LOAD FACTOR The buckling load safety factor BLF is expressed by a number by which the applied load must be multiplied in order to obtain the buckling load magnitude. Pcr BLF = Papp Pcr - critical load Papp - applied load 5 COLUMN Model file COLUMN.sldprt Model solid Material 1060 alloy Restraints edge support Load 1000 N compressive load Split line restrained in all directions Objective • calculate buckling load and buckling load factor • analyze several modes of buckling Split line restrained in y direction 1,000 N compressive load to split line 6 COLUMN First buckling mode Analytical results FBUCKLING FEA results 2 EI l2 Load factor 1.576 FBUCKLING 1.576 * 1,000 N = 1,576 N E = 6.9*105 MPa I = 208.33 mm4 L = 300mm FBUCKLING = 1,576 N 7 I BEAM support Model file I BEAM.sldprt Model solid Material Alloy steel Restraints as shown Load as shown 2500N Objective • calculate safety factor to yield • calculate safety factor to buckling 8 PLASTIC TABLE Model file PLASTIC TABLE.sldprt Model shell Thickness 2mm Material ABS Restraints as shown Load 100N vertical load 100 N vertical load Objective • meshing on faces of solid geometry • analysis of buckling load • calculate static load safety factor • exercise proper support definition All legs can slide • soft springs solution option 9 PLASTIC TABLE Solid geometry Surface geometry Shell element mesh Buckling analysis results 10