Residual Stresses, Stress Relieving and CQ1-9

By: Dan Sebastian

What are we going to talk about

1.

Basic metallurgy and how/why do we get residual stresses

2. How residual stresses are created

3. Good stresses vs. bad stresses

4. Shot peening

5. How does stress relieving effect residual stresses

6. Is there a difference in coiling methods

7. CQI-9 and why it is related to residual stresses a. Systematic control b. Physical control

Basic Metallurgy

Iron-Carbon Phase Diagram

TTT Curves

FCC Structure

BCC Structure

BCT Tetragonal Structure

Size Effect of Cubic Structure

Time Temperature Transformation (TTT)

Face Center Cubic (FCC) Structure

Austenite

Body Center Cubic (BCC) Structure

Pearlite

Ferrite

Lower Bainite

Body Center Tetragonal Cubic (BCT) Structure

Martensite

Martensite is 4.3 % larger by volume

How Residual Stresses are Created

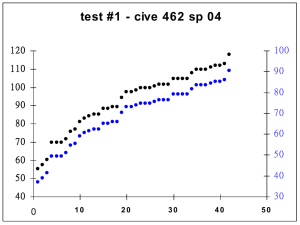

Stress-Strain Diagram

Bending Stresses

Torsional Stresses

Compressive Stresses

Multi-Stresses

Bending Stress

Torsional

Stress

Compressive

Stresses

Multi-Stresses

1. Forces vectors are in different direction to the residual stresses

2. Coil springs a. Torsion b. Bending c. Compressive d. Shear

3. Torsion Springs-Bending

4. Metal Stampings a. Bending b. Shear

Good Stresses vs.

Bad Stresses

Good Stresses:

1. Directly opposite to the creating force (uni-directional) a.

Bending i. Torsion Springs ii. Leaf Springs b. Compression Springs i. Set Out c. Belleville Washers i. Die Roll S t1

& S t2

Good Stresses vs.

Bad Stresses

2. Adding Compressive Stresses a. Shot Peening Compression Springs i. Non-Stress relieved b. Shot Peening Compression Springs i. Stress relieved c. Leaf Springs (one side)

Good Stresses vs.

Bad Stresses

Bad Stresses:

1. In direction of the creating force

2. Multi-Directional creating force a. Compression Springs b. Torsion Springs that open c. Compression Springs that are used in Extension

Shot Peening

How Does it Work

Shot Peening

How Does it Work

What is important:

1. Intensity-Almen Strip

2. Coverage-Optical Examination

Negative Consequences:

1. Poor Coverage (Competing Fields)

2. Bending Stresses Post Peening

Stress Relieving

How Does it Work

1. Equalizing Energy Fields a. Under Stress Relieving-Some Stress Remain b. Optimum occurs @ Material Change (tempered material) c. Equilibrium between strain strengthening and forming

2. Restoration of Physical Properties

IS There a Difference in

Coiling Methods

Residual Stresses?

• Single Point Coiling

• Dual Point Coiling

• Forming Through the Quill

Proper Stress Relieving is Energy Dependent

Not Related to Forming

The forming method could effect other characteristics but is not stress related

AIAG CQI-9 Requirements for

Stress Relieving of Springs

E1.2 Continuous strip chart and/or data loggers

Systematic requirement to provide proof of temperature exposure

Physical Control continuous SPC

E2.4 Temperature Uniformity Surveys (TSU) shall be performed annually and after major re-build

Systematic requirement to provide proof of temperature is controlled with in tolerance limits in every part of the heating chamber

Physical Control continuous SPC control charts are definitive documentation in real time with no time lap

E3.1 Monitor primary temperature control instruments requiring over and under temperature control alarms and a sign off every 2 hours or between lots

Systematic requirement to provide proof that temperature does not go over or under set limits and documentation that it is

Measured to be accurate every 2 hours

Physical Control continuous SPC control charts are definitive documentation in real time with no time lap

E3.6 Monitor time in furnace cycle or belt speed twice/shift and after any change in belt speed

Systematic requirement to provide proof that temperature was reached and was at the proper temperature for the prescribed time

Physical Control continuous SPC control charts are definitive documentation that all the parts are exposed to the temperature for the appropriate amount of time

AIAG CQI-9 Requirements for

Stress Relieving of Springs

E4.1 Microstructure shall be checked with each production run or each shift at a minimum

Systematic requirement to provide metallurgical proof that exposure

Physical Control after SMI review with AIAG the realized that this was not necessary as there was no way to optically see a difference

Note: With the establishment of an industry standard any deviation from the standard could affect your exposure in any product liability claim

What Did We Talk About?

1. Basic metallurgy and how/why we get residual stresses

2. How residual stresses are created

3. Good stresses vs. bad stresses

4. Shot Peening

5. How does stress relieving effect residual stresses

6. Is there a difference in coiling methods

7. CQI-9 and why is it related to residual stresses a. Systematic control b. Physical control