Lecture 22

Mechanics of Materials – MAE 243 (Section 002)

Spring 2008

Aaron Kessman, substitute for Dr. K.A. Sierros

CHAPTER 7

ANALYSIS OF

STRESS

Overview

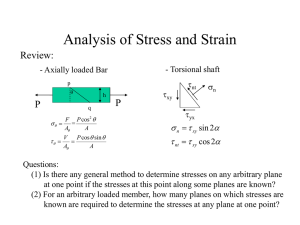

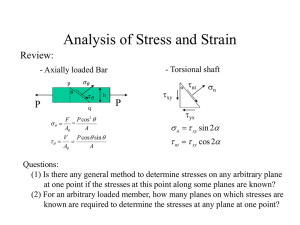

• Introduction – haven’t we been analyzing stress the whole time???

• 7.1-2 Plane stress – how uniaxial normal stress creates a shear component

• Problem solving example

• 7.3 Principal stresses and max shear stress – will the material break under loading?

• Problem solving example

Introduction

• Up till now, you’ve been dealing mostly with the big picture: uniaxial loading, torsion, and some combined loading in 2-D and 3-D.

• The end result has been to solve for the stress/moment at a given location on some loaded object – either explicitly or by a shear/moment diagram.

• Now we’ll take a microscopic look at the combined stresses and the effects of those loadings on the fabric of the material that is being loaded.

Introduction – stresses at a point

• When a body is loaded by normal and shear stresses, we can consider any point in that body as a stress element .

• The stress element can be depicted by a little square (in 2-D

– or more correctly a cube in 3-D) with the stresses acting upon it. We’ll just ignore 3-D for the meantime…

*https://ecourses.ou.edu

Plane Stress – components and conventions

• And that’s what we mean by

plane stress

: the 2-D representation of combined stresses on the four faces of a stress element

• Two normal stress components, s x

, s y

• One shear stress component t xy

– Which btw, t xy

= t yx

Elements in plane stress, note sign conventions:

(a) three-dimensional view of an element oriented to the xyz axes,

(b) two-dimensional view of the same element, and

(c) two-dimensional view of an element oriented to the x

1 y

1 rotated by some angle q from original axes -

For now we’ll deal with plane stress , the 2-D biaxial stress projection of the 3-D cube

Plane Stress – How do we look at stresses in rotation?

• If you were to rotate that little square stress element some angle q

, what would happen?

• Well, stresses aren’t vectors, so they can’t be resolved the same

(easy) way.

• We have to account for:

– Magnitude

– Direction

– AND the orientation of the area upon which the force component acts

Stress Transformation - equations

• The stress transformation is a way to describe the effect of combined loading on a stress element at any orientation.

• From geometry and equilibrium conditions ( S

F = 0 and

S

M = 0), s x

1 t x

1 y

1

s x

s y

s

2 x

s y

2

s x

s y sin(

2 cos(

2 q

)

t xy

2 q

) cos(

t xy

2 q

) sin( 2 q

) s y

1

s x

s y

2

s x

s y

2 cos( 2 q

)

t xy sin( 2 q

)

s x

1

( q

90 º )

Stress Transformation - Ramifications s x

1

s x

s y

2

s x

s y

2 cos( 2 q

)

t xy sin( 2 q

) t x

1 y

1

s x

s y

2 sin( 2 q

)

t xy cos( 2 q

)

• Given stresses at one angle we can calculate stresses at any arbitrary angle

• Even a uniaxial loading ( s x loadings upon rotation

) will create both perpendicular ( s y

) and shear ( t xy

)

• Why this is important:

If any of the transformed stresses at angle q exceed the material’s yield stress, the material will fail in this direction, even if it was loaded by lower stresses.

• Sometimes the way this works out is failure by shear, which is not obvious.

Materials are often weaker in shear.

*https://ecourses.ou.edu

Stress Transformations – Example 7.2-11

Approach:

1. Determine s x

, s y

, t xy

, q

2. Plug

3. Chug s x

1 t x

1 y

1

s x

s

2 x s

2 y s y

s x sin(

s y

2

2 q cos(

)

t xy

2 q

)

t xy cos( 2 q

) sin( 2 q

) s y

1

s x

s y

2

s x

s y

2 cos( 2 q

)

t xy sin( 2 q

)

Principal Stresses and Maximum Shear Stress

• If material failure is what we ultimately care about, then we really want to know what are the

– maximum and minimum normal stresses

– maximum shear stress

– orientation ( q

) at which these occur

• These are called the principal stresses ( s

1 maximum shear stress ( t xy

).

, s

2

) and

• The equations for these can be found from the stress transformation equations by differentiation ( ) and some algebraic manipulation.

d s d q

• This is really just a more general look at the material in the previous section.

s

1

, s

2

, t xy

,

and

q

- equations

s x

s y s avg s

1,2

tan( 2 q p

)

s x

2

2

s

( s y x

t xy

s

) / 2 y s

2 y

2

t xy

2 q p

= planes of principal stresses q p

= q p 1

, q p 2

, 90º apart no shear stress acts on the principal planes tan( 2 q s

) t max

IP

( s x s

2 y

2

s t xy y

) / 2

t xy

2 s

1

s

2 t max

2 q s

= planes of max shear stress q s

= q s 1

, q s 2

, 90º apart, 45º offset q p t maxIP

= max in-plane shear stress

Summary

• Principal stresses represent the max and min normal stresses at the point.

• At the orientation at which principal stresses act, there is no acting shear stress .

• At the orientation at which maximum in-plane shear stress acts, the average normal stress acts in both normal directions (x, y)

• The element acted upon by the maximum in-plane shear stress is oriented 45º from the element acted upon by the principal stresses

*https://ecourses.ou.edu

Principal Stresses and Max. Shear Stress - Example 7.3-18

Approach:

• Determine s x

, t xy

• Find s y

( s x

, t xy

, t

0

)

• Find numerical range t max

IP

s

2 y

2

t xy

2 s y cannot be = 0 because at some angles the combined effect will raise t xy above t

0

.