Tempering martensite - Cast3M

advertisement

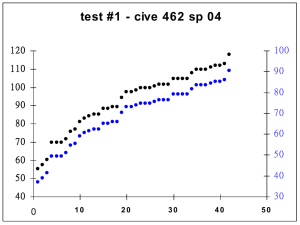

Club Cast3M 2010 Prediction of (residual stresses and) microstructural state after multi-pass GTA-Welding of X10CrMoVNb9-1 martensitic steel Farah Hanna*,***, Guilhem Roux** Olivier Asserin*, René Billardon*** * CEA, DEN, DM2S, SEMT, LTA, 91191 Gif sur Yvette, France. ** CEA, DRT, LITEN, DTBH, LCTA, 38054 Grenoble, France. *** LMT-Cachan, ENS de Cachan/CNRS/UPMC (University Paris 6), 94235 Cachan, France. Industrial background and motivations -Thick forged components assembled by multipass GTAWelding - Martensitic steel X10CrMoVNb9-1 a possible candidate for Very High Temperature Reactors - Numerical simulation of welding process MUSICA test case Numerical simulation of multi-pass GTAWelding Initial state after welding (microstructure, residual stresses,…) 2 X10CrMoVNb9-1 steel - Phase changes Pseudo-binary equilibrium diagram Continuous Cooling diagram Fe-Cr à 0.1% wt C [Easterling, 1992] "T91" [Duthilleul, 2003] During heating (1st pass) Base material (tempered martensite) → Austenite → δ Ferrite → Liquid During cooling Liquid → δ Ferrite → Austenite → Quenched martensite [Roux 2007] [Roux 2006] [Hanna 2009] During subsequent heating (2nd and following passes) [Hanna 2010] Quenched martensite → Tempered martensite → Austenite → … 3 Martensite tempering Heat treatments Tempered @ 500°C for 6 min. Tempered @ 500°C for 1h Martensite tempering → Carbides precipitation Tempered @ 750°C for 5h30 4 Measurement of carbides precipitation Indirect measurement of carbides precipitation through the percentage of free carbon in the matrix by Thermo-Electric Power measurements (Seebeck effect) Specimen Hot junction Sspecimen Sref Cold junction V (chemical composition) T 5 Measurement of carbides precipitation TEP measurements after different tempering heat treatments (TT , tT ) TEPQ = 10.78 TEPAR = 11.49 Precipitation evolution Tempering evolution TEPQ = 10.78 TEPAR = 11.49 Definition of the “tempering factor” xT TEP TEPQ TEPAR TEPQ 6 Modelling of martensite tempering Fick law J D grad C C 1D J D x Conservation law C C J 1D div J t t x Isothermal case r+h x Dt Temperature dependence of the diffusion coefficient and generalisation H x D0 exp t RT 1 n x H 1 n 1 D0 exp x n RT Proposed evolution law for tempering factor xT xT H 1 n 1 D 0 exp 1 x T H T TTTh xT n RT 7 Identification of tempering model xT H 1n 1 D0 exp xT 1 xT H (T TTTh ) n RT D0 2.41013 H 278.2 KJ/mol n 3.61 •coherent with Cr bulk diffusion and carbides growth-coalescence •not applicable to tempering at T < 475°C (with long holding times) (secondary ageing, embrittlement) 8 Hardness vs. tempering factor x 1 HVTM HVQ HVQ HVAR exp T x 0 HVAR 185 HVQ 513 x0 0.374 9 Modelling the thermo-metallurgical-mechanical behaviour (Phase changes enthalpies) Phase changes Thermal Standard anisothermal mechanical behaviour for each phase MODEL Metallurgical Mechanical Multiphasic behavior UMAT formalism integration Lois Castem CHAB_NOR_R CHAB_NOR_X CHAB_SINH_R CHAB_SINH_X explicit integration 10 Modelling the multiphasic behaviour Two scale mixing mechanical law: •Reuss approach 11 11 11(1) •Voigt approach [Goth 2002] 11 x(1)C(11) x(2)C(21) 11( 2) 11 11(1) 11( 2) 11 x(1)C(1) x( 2)C( 2) •Hill & Berveiller-Zaoui type approach [Cailletaud, 87] [Pilvin, 90] Intergranular accommodation variables [Robert 2007] for welding 11 Modelling the multiphasic behaviour •Hill & Berveiller-Zaoui type approach [Cailletaud, 87] [Pilvin, 90] Intergranular accommodation variables [Robert 2007] for welding TRIP (Transformation Induced Plasticity): [Hamata 1992] [Roux 2007] [Coret 2001] 12 Mechanical behaviour of each phase Anisotropic elastoviscoplastic mechanical behaviour Norton Law Isotropic hardening avec Linear and non-linear Kinematic hardening avec Tempering martensite (reception state) essais de viscosité en phase martensitique revenue 700 800 600 600 T=20°C T=400°C 400 500 T=500°C T=20°C T=400°C 400 F/So (MPa) F/So (MPa) essais de viscosité en phase martensitique revenue T=500°C T=700°C 300 T=900°C T=1000°C 200 T=700°C 200 T=900°C T=1000°C 0 -0.05 -0.04 -0.03 -0.02 -0.01 0 0.01 0.02 0.03 0.04 0.05 -200 -400 100 -600 0 0 0.01 0.02 0.03 0.04 dL/Lo 0.05 0.06 0.07 0.08 -800 dL/Lo 13 Mechanical behaviour of each phase Quenched martensite essais de viscosité en phase martensitique trempée essais de viscosité en phase martensitique trempée 1200 1500 1000 1000 T=20°C T=200°C 500 F/So (MPa) F/So (MPa) 800 600 T=20°C 400 T=300°C T=400°C 0 -0.05 -0.04 -0.03 -0.02 T=200°C -0.01 0 0.01 0.02 0.03 0.04 0.05 -500 T=300°C T=400°C 200 -1000 0 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 -1500 dL/Lo dL/Lo Tempering occurs for T> 400°C Austenite essais de viscosité en phase austénitique essais de viscosité en phase austénitique 450 40 400 35 T=200°C 350 T=300°C 30 T=400°C T=1000°C T=500°C T=600°C 250 T=700°C T=800°C 200 T=900°C T=1200°C T=1300°C 20 T=1500°C 15 T=1000°C 150 T=1100°C 25 F/So (MPa) F/S (MPa) 300 10 100 5 50 0 0 0 0.01 0.02 0.03 0.04 dL/Lo 0.05 0.06 0.07 0.08 0 0.01 No kinematic hardening 0.02 0.03 0.04 dL/Lo 0.05 0.06 0.07 0.08 14 Mixing tempered and quenched martensites Experimental procedure Model for quenched + tempered martensite experiments at xt=0.6 (500°C) + essai à 300°C 1200 contrainte (MPa) 1000 800 linear evolution for simulations 600 400 •Tempering has a softening effect on elasticity and isotropic hardening martensite martensite revenue 50%-50% MT=20%-MB=80% 200 •No dependance of temperature on mixing evolution MT=80%-MB=20% 0 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 •Linear dependance of mechanical parameters with tempering state ([Inoue 85] approach) 0.08 dL/Lo 15 Mixing austenite and quenched martensite essai à 300°C 1200 1000 contrainte (MPa) βeta model: 800 600 400 200 martensite austénite 0 0 0.01 0.02 0.03 0.04 50%-50% 0.05 0.06 MT=20%-AU=80% dL/Lo MT=80%-AU=20% Reuss approach: 0.08 Voigt approach: essai à 300°C essai à 300°C 1200 1200 1000 1000 martensite 800 austénite 50%-50% MT=20%-AU=80% MT=80%-AU=20% 600 400 200 contrainte (MPa) contrainte (MPa) 0.07 martensite 800 austénite 50%-50% MT=20%-AU=80% MT=80%-AU=20% 600 400 200 0 0 0 0.01 0.02 0.03 0.04 dL/Lo 0.05 0.06 0.07 0.08 0 0.01 0.02 0.03 0.04 dL/Lo 0.05 0.06 0.07 0.08 16 Simulation of dilatometry tests Free dilatometry curve: TRIP experiments: 0.015 0.01 0.005 0MPa 100MPa 0 50MPa 0 200 400 600 800 1000 25MPa 1200 -25MPa -0.005 -50MPa 100MPa -0.01 17 Simulation of Satoh experiment T Coupling between hardening of mother and daughter phases and TRIP [Petit-Grotabussiat 2000] for 16MND5 alloy modele serie 500 modele en B 400 modele parallele 300 contrainte (MPa) Overestimation of TRIP effect 600 experimental cycle n°1 200 100 0 -100 0 200 400 600 800 1000 1200 1400 -200 -300 -400 -500 No plasticity of quenched martensite phase temperature (°C) Very low influence of homogenization rule 18 Simulation of Disk Spot experiment Experimental set-up : [Cavallo 1998] [Cano 1999] torche TIG R=50mm capteurs de déplacement 8mm thermocouples Test at DEN/DM2S/SEMT/LTA Inverse analysis identification of heat source intensity and spatial distribution [Roux 2006] 19 Simulation of Disk Spot experiment Prediction of final metallurgical state: δ -ferrite Residual stresses on upper surface (X ray diffraction measurements): 450 450 experimental RX residual stresses 350 simulated residual stresses for Beta model 250 simulated residual stresses for Reuss approach simulated residual stresses for Voigt approach 150 50 -50 5 10 15 20 25 30 35 40 45 50 -150 Experimental residual stresses for Beta model simulated residual stresses for Beta model simulated residual stresses for Reuss approach simulated residual stresses forVoigt approach 250 150 50 -50 5 10 15 20 25 30 35 40 45 50 -150 -250 -350 Tangential residual stresses (MPa) Radial residual stresses (MPa) 350 -250 Distance from disk center (mm) Radial shift (bad HAZ prediction?) Distance from disk center (mm) 20 Simulation of Disk Spot experiment Residual stresses on upper surface (X ray diffraction measurements): 500 500 Experimental residual stesses 400 simulated residual stresses for Beta model simulated residual stresses for Reuss approach simulated residual stresses for Voigt approach 300 200 100 0 0 5 10 15 20 25 30 35 -100 -200 -300 40 45 50 Tangential residual stresses (MPa) Radial residual stresses (MPa) 400 Experimental residual stresses 300 simulated residual stresses for Beta model simulated residual stresses for Reuss approach simulated residual stresses for Voigt model 200 100 0 0 5 10 15 20 25 30 35 40 45 50 -100 -200 Distance from disk center (mm) -300 Distance from disk center (mm) Again overestimation of TRIP effect Similar stress distribution with Beta model and Voigt Approach 21 Simulation of Disk Spot experiment Residual stresses on half thickness (Neutron diffraction measurements): 800 600 400 simulated residual stresses for Beta model simulated residual stresses for Reuss approach 300 simulated residual stresses for Voigt approach 200 100 0 5 10 15 20 400 25 30 35 40 45 50 Tangential residual stresses (MPa) Experimental residual stresses Experimental residual stresses 500 simulated residual stresses for Beta model 400 simulated residual stresses for Reuss approach 300 simulated residual stresses for Voigt approach 200 100 0 5 10 15 20 25 30 35 40 45 50 -200 Experimental residual stresses -300 300 -200 600 -100 -100 Normal residual stresses (MPa) Radial residual stresses (MPa) 700 500 Distance from disk center (mm) Distance from disk center (mm) simulated residual stresses for Beta model 200 simulated residual stresses for Reuss approach simulated residual stresses for Voigt approach 100 0 5 10 15 20 25 30 35 40 45 50 -100 -200 Distance from disk center (mm) 22 Multipass MUSICA experiment Experimental set-up at DEN/DM2S/SEMT/LTA TIG multipass welding TC3 TC2 TC1 Temperature measurements Inverse identification of heat source for each pass [Hanna 2006] 23 Multipass MUSICA experiment Quenched martensite Prediction of final metallurgical state: Strong tempering effect of previous passes Without tempering 1 With tempering vertical displacement (mm) 0.5 0 0 1000 2000 3000 4000 5000 6000 7000 8000 9000 Vertical distorsion -0.5 w ith tempering -1 w ithout tempering -1.5 -2 -2.5 tim e (s) 24 Multipass MUSICA experiment Residual stresses: Sxx Syy With tempering Without tempering Szz 25 Conclusion & perspectives •Differential model has been developed to model phase change During cooling : - martensite transformation During heating : - austenitization of quenched and tempered martensites Not presented here - tempering of martensite •This thermometallurgical model allows for the prediction of hardness profiles through welds by simple post-processing of heat transfer analyses •This thermometallurgical model has been coupled to elasto-viscoplastic constitutive equations identified for each metallurgical phase •A simple homogenization approach has been used associated to martensitic transformation •This model could be applied for bainitic transformation (case of the 16MnD5 steel) •This thermometallurgical mechanical model has been implemented in Cast3M and validated in terms of residual stresses prediction for welding experiments 26