4-Allowable stresses

4-Chapter

Allowable stresses

contents

2.6.1(p8) Compression element, Axial or bending

Allowable crippling stress in web q all

Introduction

The actual stresses in any part of steel bridge must not exceed the elastic limit of the material otherwise permanent deformation would occur. All structural calculations are approximate even if all loads are carefully considered. In trusses neglect the secondary stresses due to the rigidity of joints.

The forces in members are determined under the assumption that the connections are hinge and the forces along the members are axial. Only the primary stresses can be calculated. In some cases the secondary stresses may reach 30 – 60 % of the primary stresses. The analyses neglect also the torsion in the main girders due to the deflections of the X-girders. The unequal distribution of stresses over the cross section due to bolts holes hasn’t taken into consideration

•The allowable stresses (maximum stresses used in the calculation) must therefore be lower than the elastic limit.

The more accurate calculations of steel bridge and the better shop work, the higher allowable stresses may be taken. Also, in the calculation if all possible forces are taken into account the allowable stresses can be taken higher than in case that only D.L., L.L, and Impact are considered.

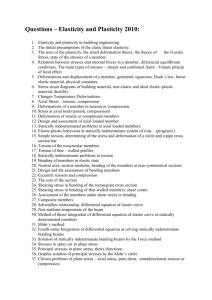

The permissible stresses for standard grade structural steel determined according to the grade of steel. Structural sections shall be classified, depending on dw/tw for web and c/tf for flanges under compression, axial bending, to compact, noncompact, and slender sections as shown Fig(4-1)

Figure-4.1

F y and F u

(t/cm 2 ) depend on the thickness t(1.4-p2).

Grade of steel

ST37

ST44

ST52

Fy t

40mm

Fu

2.40

2.80

3.60

3.60

4.40

5.20

100mm

t >400mm

Fy Fu

2.15

2.55

3.35

3.40

4.10

4.90

2.2.1

(p6) Primary + additional stresses ( wind load or earthquake loads, lateral shock, etc.

)

2.2.3

(p7) Additional stresses

Additional stresses (allowable) = Primary stress

1.20

2.3

(p7) Secondary stresses in truss members

1. Chord member's depth > 1/10 of their length .

Diagonal member's depth > 1/15 of their length .

2. Truss with sub-panel.

Reduce 20 % of the allowable stress

2.6.1(p8) Compression element, Axial or bending

Compact

Noncompact

Selender

d w t w

Factor depends on: and

C f t f

Factor

F y

1. Support of element ((One side (unstiffened element) or two sides (stiffened element)) and shape of the cross section, I, C,

, L, etc.

2. Load on element [(N) or (M) or (M+N)]

(p9,10,11-Table 2.1.a,b&c)

2.6.2

(p13) Axial tension

F t

0 .

58 F y

40 t

mm

40

t mm

100

F y mm

F y

F rom clause 1.4

, get F y

Hence for, t

40

40 mm

t mm

F

F t

F t t

1 .

40 t / cm

2

ST

1 .

60 t / cm

2

ST

2 .

10 t / cm

2

ST

100 mm

F

F t

F t t

1

1

.

30

.

50 t t

/

/ cm

2

ST cm

2

ST

37

4 4

5 2

37

4 4

2 .

00 t / cm

2

ST 5 2

2.6.3(p13) Allowable shear stress q all q all

0 .

35 F y

40 t

40 mm

mm t

100

F y mm

F y

F rom clause 1.4, get F y

Hence for, t

40 mm

q

q q all all all

0 .

84 t / cm

2

ST 37

0 .

98 t / cm

2

ST 4 4

1 .

26 t / cm

2

ST 5 2

40 mm

t

100 mm

q all

q q all all

0 .

75 t / cm

2

ST 37

0 .

89 t / cm

2

ST 4 4

1 .

17 t / cm

2

ST 5 2

2.6.3.1

(p13) Effective web area

Rolled section = Total height

t w

Built up section = Web height

t w

2.6.3.2

(p14) Shear buckling of web d w t w

105

F y

d

1 d

Stiffened web

1

K q

4

5 .

34

2

1

K q

5 .

34

4

2 d

1 d

If

Unstiffened web

=

K q

= 5.34

d w t w

45

K q

,

q

F y

0 .

80

no web buckling occur q p

= 0.35 F y

If, d w t w

45

K q

F y

Check web buckling

q d w

q

0 .

80

t F y w

57

0 .

80

q

K q q

1 .

20

b

0 .

35 F y q b

1 .

50

(no web buckling occur)

0 .

625

q

0 .

35 F y

q

1 .

20

q b

0 .

90

q

0 .

35 F y

2.6.4(p15) Axial compression k

l r

F c

0 .

58 F y

( 0 .

58 F y

10

4

0 .

75 )

2

t t

40 mm

40 mm

get F y from 1.4

t

40 mm 40 < t < 100 mm

Grade of steel

ST37

F c

(t/cm 2 ) F c

(t/cm 2 )

F c

1 .

40

0 .

000065

2

F c

1 .

30

0 .

000055

2

ST44

ST52

F c

1 .

60

0 .

000085

2

F c

1 .

50

0 .

000075

2

F c

2 .

1

0 .

000135

2 F c

2 .

0

0 .

000125

2

•For compact and Non-compact sections use full area(Table2.1-p9-11).

•For slender sections use effective area(Tables 2.3&2.4-p23&24).

•For one angle reduce F c

%(p15). by 40

2.6.5(p16) Bending stress

1For compact sections and the laterally unsupported length (L limited by: u

)of the compression flange is

(L u is the smaller of)

Box sections

L u

84

F y

b f

Or

L u

137

84

M

1

M

2

b f

F y

I -shape sections

L u

20 b f

F y

Or

L u

1380 b f d

F y

C b

-

C b

From Table2.2

Then

· F b

= 0.64

F y

(M x

) Boxand Ishapes Clause 2.6.5.1

· F b

= 0.72

F y

(M y

)

· F b

= 0.64

F y

(M y

Ishapes Clause

) Box shapes Clause

2.6.5.2

2.6.5.3

11For Non-compact sections:

· F b

= 0.58

F y

(M x

& M y

) Box shapes Clause 2.6.5.4

22For slender (Box and Ishapes) and Non-compact ( Ishapes) sections:

·

·

Tension

F bt

= 0.58

F y

Compression

·

1L u

L all

F bc

= 0.58

F y

Clause

Clause

2.6.5.5

2.6.5.5

·

·

2L u

> L all i – ( Shallow thick flanged section L u xt f

/ b f xd >10 (P18))

For any value of

F ltb 1

L u

800

d / A f

C b

0 .

58 F y (eq 2.23) ii - ( Deep thin flanged section L u xt f

/ b f xd <0.4 (P18))

84

F ltb 2

C b

L u

F y r t

0 .

58 F y

(eq2.24)

84

C

F b y

L u r t

188

C b

F y

F ltb 2

0 .

64

( L u

1 .

/

176 r

T

)

2

F

10

5

C b y

F y

0 .

58 F y

L u r t

188

C b

F y

F ltb 2

12000

( L u

/ r

T

)

2

C b

0 .

58 F y

F ltb

F

2 ltb 1

F

2 ltb 2

0 .

58 F y

(eq 2.25)

(eq2.26)

·

(eq2.27)

-

II - For Channels( p21) F ltb

;

F ltb

L u

800

d / A f

C b

0 .

58 F y

( M x

)

(eq2.29)

· III - For slender sections use effective width (b e

) and the stress for non-compact(p21).

Effective width b e

2.3& 2.4 – p23&24); for slender sections(Table

K

f

2

f

1

1

2

16

0 .

112

1

2

0 .

5

1

( Table 2.3

)

· For any value of get from tables 2.3, and 2.4 for stiffened and unstiffened elements respectively.

Calculate

Calculate

b / t

44

F y

K

(plate slenderness)

0 .

15

0 .

05

2

1 .

0 b e

=

b

Summary Table for Lateral Torsional Buckling

(L u

> L all

)

F ltb 1

L u

800

d / A f

C b

84

C b

F y

L u r t

84

C b

F y

L u r t

188

C b

F y

L u r t

188

C b

F y

For all

F ltb

0 .

58 F y

F ltb 2

0 .

58 F y

F ltb 2

0 .

64

( L u

1 .

/

176 r

T

)

2

10

5

F

C b y

F y

F ltb 2

12000

( L u

/ r

T

)

2

C b

F ltb

F

2 ltb

F

2

1 ltb 2

2.6.6 (p22)Allowable crippling stress in web q all

F crp

0 .

75 F y

t t

40

40 mm mm

F rom clause 1.4, get F y

In tension members we get smaller cross sections by using high tensile stresses St. 52.

While in compression members we get smaller section if l/i is less than 100 but if l/i is more than

100 we get same section for all kinds of steel .

2.6.7 Combined stresses

In a continuous beam we have a state of combined shear and bending

F

1 , 2

f

2

f

2

q

2 f pt

f pc

This stress may be greater than the bending stress in the outside fibers.

The modern theory of equivalent structure is given by;

F e

2

3 q

2

1 .

10

f pt

2.6.7.1- Axial Compression And Bending f ca

F c

f bcx

F bcx

1

f bcy

F bcy

2

1 .

0

When f ca

F c

0 .

15

1

2

1.0

1

1

C mx

F f ca

EX

,

2

1

C my

F f ca

EY

F

EX

7500

2

, F

EY

7500

2

C mx

, C my from code

2.6.7.2- Axial Tension And Bending f ta

F t

f btx

F btx

f bty

F bty

1 .

0