A centrifuge is a piece of equipment, generally driven by a motor

advertisement

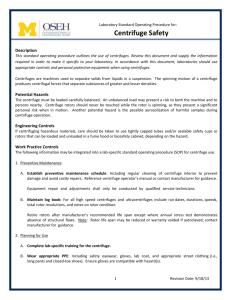

Centrifuges A centrifuge is a piece of equipment, generally driven by a motor, that puts an object in rotation around a fixed axis, applying force perpendicular to the axis. The centrifuge works using the sedimentation principle, where the centrifugal force is used to separate substances of greater and less density. Terminology Pellet - Material that has accumulated on the bottom of a tube after centrifugation (if any) is called the "pellet“. Material comprising the pellet is said to have "sedimented". Supernatant - The overlying fluid is called the "supernatant solution" or simple the "supernate“. Relative centrifugal force or Centrifugal effect - The force that the sample is subjected to, is expressed as some number times the force of gravity, or relative centrifugal force (RCF). Critical speed - Critical speed is the speed when the frequency of rotation matches the natural frequency of the rotating part and any vibration induced by slight imbalance in the rotor is highly magnified, resulting in high stresses and even failure of the equipment. Almost all centrifuges operate above the critical speed. General Principles of Centrifuges Basis of separation: -Size –Shape -Density Methodology: - Utilizes density difference between the particles and the medium in which these are dispersed - Dispersed systems are subjected to artificially induced gravitational fields. - The centrifugal force causes the sedimentation of heavier solid particles. Supernatant Induced gravitational field Suspension In process Precipitate Separation complete Centrifugal Force Let us consider a body of mass m rotating in a circular path of radius r at a velocity v. The force acting on the body in a radial direction is given by: F= mv 2 r Here, F = centrifugal force m = mass of the body v = velocity of body r = radius of circle of rotation The same body is experiencing gravitational force. It can be expressed as: G = mg where, G = gravitational force , and g = gravitational constant The centrifugal effect is the ratio of the two forces, so that: C=F/G = mv2 / mgr = v2 / gr But: v = 2πrn Where n = speed of rotation. F / G = (2πrn)2 / gr = 4π2r2n2 / gr = 2 π2n2d / g ------------------------ (1) Where d = diameter of rotation. So, The gravitational constant has a value of 9.807 m/s2, so that equation (1) may be simplified to: Centrifugal effect = 2.013 n2d Provided that n is expressed in s-1 and d is in meter. Materials of Construction A centrifuge is comprised of two major components: 1. The drive mechanism: The drive mechanism is the source of rotary motion, and is powered by an electric motor, by air pressure, or by oil turbines, depending upon the type of centrifuge. 2. The Rotor The rotor is the large rotating element of a centrifuge into or onto which samples are loaded. It is driven about a fixed axis (or shaft) by the drive mechanism, with expenditure of large amounts of energy. Types of rotors There are two fundamental types of rotors: 1. Fixed-angle rotor: In fixed angle rotors the tubes containing samples are placed into shields or openings in the rotor at one particular pre-set angle. The tubes are thus tilted with their tops closer to the shaft than their bottoms, and remain in that fixed position during the run, regardless of rotor speed. 2. Swinging-bucket rotor: In swinging bucket rotors, the tubes are initially vertical. The bottoms of the sample tubes then swing outward freely as the shaft rotates, and the tubes are actually horizontal during the run. By the time the centrifuge stops, however, the tubes have returned to their starting vertical position. Swinging-bucket rotors are particularly useful for sedimenting a sample through a density gradient A. Fixed Angle Rotor B. Swinging Bucket Rotor Application of Centrifuges • Production of bulk drugs: In the bulk drug industry, whenever a crystalline material is to be separated from a suspension, e.g., aspirin is separated from its mother liquor by centrifugation. • Production of biological products: a) Separation of blood cells. b) Purification of insulin by selectively precipitating other fraction of proteins. c) Separation of most of the proteinaceous drugs and macromolecules. • Biopharmaceutical analysis of drugs: Drugs present in the blood, tissue fluids and urine are normally present in the form of colloidal dispersion. Centrifugation is used for separating the drugs which is essential for the evaluation of pharmacokinetic parameters and bioequivalence studies. • Evaluation of suspension and emulsion: Centrifugation method is used as a rapid empirical test parameter for the evaluation of suspension and emulsion. e.g., A stable emulsion should not show any signs of separation even after centrifuging at 2000-3000 rpm at room temperature. • Ultracentrifugation are used for determination of molecular weight of serum albumin, insulin etc. • Isolation of bacterial cells, fungal and actinomycete mycelium and spores from liquid growth and fermentation media is facilitated by laboratory centrifuge. • Removal of finely suspended solid matter (clarification) from aqueous or oily materials can be carried out by centrifuging at high speeds without the necessity of a filter. • Ultracentrifuge can be used for separation of virus particles which has potential industrial applications. Types of Centrifuges Centrifuges can be classified on the basis of speed, temperature. (A) SPEED The "speed" of a centrifuge is measured in revolutions per minute, or rpm. Centrifuges are generally divided into 3 categories based on their maximum attainable speed: 1. "Low-speed": to maximum of ~ 5 x 103 rpm. 2. "High-speed": to maximum of ~2 x 104 rpm. 3. "Ultracentrifuges": to maximum of ~105 rpm. (B) TEMPERATURE Centrifuges are either refrigerated or not refrigerated. Refrigerated centrifuges have a built-in refrigeration unit surrounding the rotor, with a temperature sensor and thermostat permitting selection of a particular temperature or a permissible temperature range that is maintained during centrifugation. Many biological samples are temperature sensitive, and centrifugation in the cold (say, 1-4oC) is frequently required. Centrifuges that are not refrigerated are normally used at whatever temperature the room they are in happens to be. This is typically described in research reports as "room temperature" or "ambient temperature“. Classification of Centrifuges On The Basis of Its Use Centrifuges Laboratory equipment Commercial equipment 1. Swing-out arm type 2. Angle type 3. Ultracentrifuge Batch 1. Top driven 2. Under driven Perforated bowl types Semicontinuous Sedimentation centrifuges Continuous or Supercentrifuge Vertical 1. Simple bowl 2. Bowl with plates Horizontal continuous decanters Industrial Centrifuges Sedimentation Type Centrifuges / Centrifugal Sedimenters It produces sedimentation of solids based on the difference in the densities of two or more phases of the mixture. Examples include: a) Tubular bowl centrifuges b) Conical disk centrifuges Figure: Tubular bowl Centrifuge Figure: Conical disk centrifuge Advantages of Centrifugal Sedimenters Centrifuges are compact and occupy a very small space. • The separating efficiency is very high, so that the particles are deposited very rapidly. It is suitable , if the sediment is a fluid deposit or sludge. • Two immiscible liquids are easily separated on a continuous process . • Centrifugation is the ideal technique for dealing with difficult solids; for example , substances that are slimy or compressible and would block a filter medium .e.g.. coagulated proteins. • By controlling the speed of rotation and rate of flow coarse particle are separated, while finer particles remain in the suspension. Disadvantages of Centrifugal Sedimenters • • The construction of sedimentation centrifuge is complicated due to high speed of rotation requires as special driving mechanisms. The capacity is limited. Uses of Centrifugal Sedimenters 1. 2. 3. 4. 5. Dirt and water are removed from oils. Example, in the purification of olive oil or fish liver oil, this method is used. Lanolin is recovered from the wool by scouring process. The liquid /liquid phases are separated in the extraction of drugs, for examples, manufacture of antibiotics. Bacterial enzymes are prepared by removing bacteria. Suspensions containing low concentration of solids can be separated quickly. 6. Blood plasma is separated from whole blood. 7. Starch is collected after washing and purification states. 8. In the manufacture of insulin, liquor is clarified so as to remove the precipitated proteins. 9. Stability of emulsion is examined. 10. Different particle size fractions are separated by using control of speed of rotation and rate of flow. Perforated Bowl Centrifuge / Centrifugal Filters • It’s a filtration centrifuge. • Separation occurs through a perforated wall based on the difference in the densities of solid and liquid phases. • During centrifugation the liquid phase passes through the perforated wall, while solid phase is retained in the bowl. • The solid is removed after cutting the sediment by a blade after stopping the centrifuge. Figure: Perforated bowl centrifuge Advantages of Perforated Centrifuge • The Centrifuge is very compact and it occupies very little floor space. • It can handle slurries with a high proportion of solids and even those having paste like consistency. • The final product has very low moisture content. • In this method, the dissolved solids are separated from the cake. • The process is rapid. Disadvantages of Perforated Centrifuge The entire cycle is complicated resulting in considerable labor costs. The process is intermittent, working on the batch principle. On prolonged operation, the solids may form hard cake, due to the centrifugal force, which is difficult to remove simultaneously. Uses of Perforated Bowl Centrifuge • Used for removing unwanted solids from a liquid. e. g precipitated proteins are removed from insulin. • Extensively used for separating crystalline drugs (such as aspirin) from the mother liquor. • Sugar crystals are separated using perforated basket centrifuge. THE END