Introduction to the Lathe Machine

advertisement

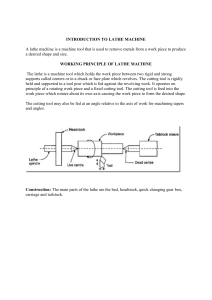

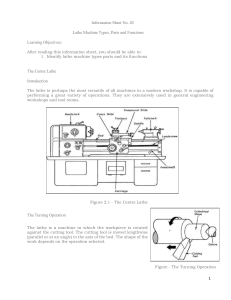

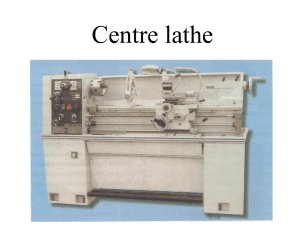

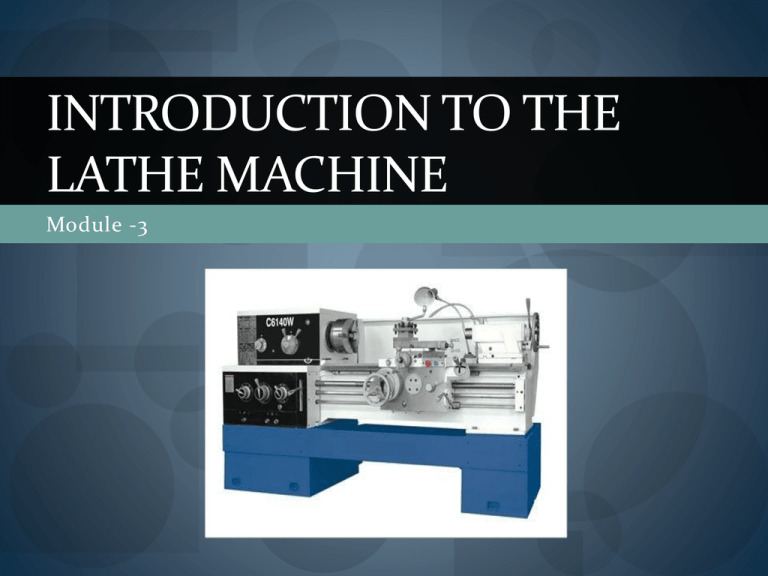

INTRODUCTION TO THE LATHE MACHINE Module -3 Module Objectives Describe how a lathe operates. Identify the various parts and attachments of a lathe and their function. Describe how the cutting tools cut materials. Implement and describe the safety rules for machining using a lathe. Select the correct cutting speed, feed, and depth of cut during machining. What is a Centre Lathe Machine? It is a power-driven, general- purpose machine tool used for producing cylindrical workpieces. As the piece of metal to be machined is rotated in the lathe, a single-point cutting tool is advanced radically into the workpiece at specified depth and moved longitudinally along the axis of the work-piece, to remove the metal in form of chips in order to make the required shape. Major parts of a lathe Machine Cross-Slide Tool holder Compound rest Tailstock Headstock Feed levers Lead screw Bed Quick-change Gearbox Feed rod Base Carriage hand wheel Split-Nut lever Carriage The most important parts of a lathe 1. Headstock Head stock provides the driving power to control the rotation of the part (workpiece) being machined. The headstock contains the spindle to which the various work-holding attachments are fitted. The most important parts of a lathe 2. Bed Its function is to provide main frame for the support of the work-piece and tool during machining. The most important parts of a lathe Carriage 3. Controls and supports Cross-slide the cutting tool, and composed of a number Saddle of parts. Power is transmitted to the carriage through the feed mechanism. This regulates the amount of tool travel per revolution of the spindle (Feed). Apron Tool rest Compound rest The most important parts of a lathe 3. Carriage Parts The saddle is fitted to the ways of the bed and slides along them (Z axis for CNC machines). 2. The apron contains a drive mechanism to move the carriage along the ways, using hand or power feed. 3. The cross-slide allows the tool to move in and out (toward or away from the operator), (X axis for CNC machines). 4. The compound rest allows the tool to move at an angle. (move in X and Z axes at the same time) 5. The tool rest is used to mount the cutting tool. 1. The most important parts of a lathe 4. Lead screw Lead screw transmits power to the carriage through a gearing and clutch arrangement in the carriage apron. The power feed lever is located on the carriage apron. The power feed lever activates either the longitudinal power feed of the carriage or the cross feed of the cross slide Lead screw The most important parts of a lathe 5. Split-nut (Half nut) lever Half-nut lever is placed on the apron and engaged for thread cutting. Thread cutting is the process of cutting screws and helical shapes. The power feed lever must be in neutral position when the half-nut is needed to be engaged. The most important parts of a lathe Tailstock 6. The function of the tailstock is to support long work-pieces during machining, and to hold some tools. Turning the hand wheel of the tailstock clockwise advances the spindle (which holds the cutting tools or center) toward the workpiece. E.g. the drill bit and boring bar, during drilling or boring operations. (Boring is the process of enlarging a hole). Lathe attachments An attachment is a device mounted on the lathe so that a wider range of operations could be performed. Workpiece holding devices There are different lathe attachments used to hold and support different shapes (round, hexagon, or irregular) and different sizes of workpieces. 1. Three-jaw universal chuck The three-jaw universal chuck holds cylindrical or hexagonal work. All three jaws move together to bring the work on center. Workpiece holding devices Two sets of interchangeable jaws are provided as the jaws are not reversible, these are called inside and outside jaws. One set is used to grip the work inside while the other is used to grip the work on the outside. Workpiece holding devices 2. Four-jaw independent chuck The four jaws are reversible and can hold work of different sizes and shapes. Each jaw may be moved independently. 3. Collet chucks Collet chucks are used to grip small-diameter workpieces. Collets are made in sets, to fit different sizes. Workpiece holding devices 4. Faceplate A faceplate is one of the workpiece holding devices. It contains more open slots or T slots so that bolts or T bolts may be used to clamp the workpiece to the face of the plate. Many types of work that can not be held in chucks may be machined conveniently when mounted on a face plate. 5. Centers Support the workpiece between the headstock and the tailstock. Workpiece holding devices 6. Follower rest Is used to support long cylindrical workpieces. It is attached to the carriage when in use, and is moved as the tool and carriage move. Follower rest 7. Steady rest Is used to support long cylindrical workpieces. It is attached directly to the machine bed. Steady rest