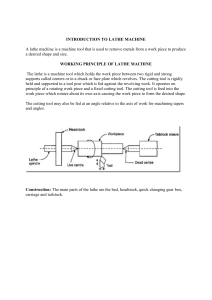

Information Sheet No. 02 Lathe Machine Types, Parts and Functions Learning Objectives: After reading this information sheet, you should be able to: 1. Identify lathe machine types parts and its functions The Centre Lathe Introduction The lathe is perhaps the most versatile of all machines in a modern workshop. It is capable of performing a great variety of operations. They are extensively used in general engineering workshops and tool rooms. Figure 2.1 - The Centre Lathe The Turning Operation The lathe is a machine in which the workpiece is rotated against the cutting tool. The cutting tool is moved lengthwise (parallel or at an angle) to the axis of the bed. The shape of the work depends on the operation selected. Figure - The Turning Operation 1 Work Produced on a Centre Lathe Generally, the lathe is used to produce cylindrical or conical jobs, plane (flat) surfaces, able to drill and ream holes, cut screw threads and other operations using special attachments. These surfaces and threads may be external or internal to the component. Figure - Work Produced on a Centre Lathe Types of Lathe Bench Type - These lathes are mounted on a bench or metal cabinet. Tool Room Type - These lathes are highly precision lathes equipped with a variety of accessories. Manufacturing Type - These are bigger, heavier and more powerful than the bench type or toolroom type. Turret and Capstan - The tool holder can accommodate up to 8 tools at a time. Special Types - The new types including CNC lathes Specifications of a Lathe A lathe is generally specified by its Swing (S) Distance Between Centres (C) The swing is the largest diameter of a workpiece that can be swung over the lathe bed and the distance between centres is the distance between the headstock and tailstock centres. However, some manufacturers specify lathes by their bed length. Figure 2.3 - Specification of a Lathe 2 Parts of a Lathe Headstock The headstock is located at the left end of the lathe bed. It contains the main spindle mechanism for obtaining various spindle speeds. The main spindle revolves on two bearings on each end of the headstock. The right end is made to fit a chuck or face plate. The main purpose of the headstock is: To transmit motive force from the motor to the main spindle by means of belts and pulleys. To provide different spindle speed and feed. Holds workholding devices such as the chuck that holds and drives the workpiece. Figure 2.4.1 - Headstock Machine Bed The lathe bed is a strong bridge like members, made from high grade cast iron and is heavily ribbed to give it rigidity, It has four ways out of which three are inverted and one flat way. The bed supports all the mountings of the lathe. The accuracy of the lathe depends largely on how straight and parallel the bed ways are. It is precisely hand scraped to high dimensional and geometrical tolerances. On the machine bed, there are slideways, it is usually a flat and an inverted-vee slideway. The outer V-way and flat-way support and guide the carriage. The inner V-way and flat-way align the tailstock with the headstock. Figure - Machine Bed 3 Tailstock It is located at the right end of the lathe, it can be adjusted along the bedway to suit the length of work. It is made from cast iron which locates the barrel. The barrel is hollow and is bored with a Morse-taper. This taper locates the taper shank of a dead centre and also taper shank drills, drill chucks, etc. The bore is co-axial with the spindle that is they have a common axis and this is a basic alignment of the lathe. The tailstock’s primary functions are: To support long workpieces. Holds tools such as drills or reamers for drilling and reaming operation. For setting centre height of tool bits. Figure - Tailstock Carriage The carriage provides various movements to the cutting tool to perform various operations on the lathe. The three movements are: Longitudinal Feed Cross Feed Angular Feed Figure - Carriage 4 The carriage consists of the following parts: Apron The apron is bolted to the front of the saddle. It contains the mechanism for moving and controlling the carriage. Power is transmitted to the carriage through a gear and clutch arrangement. Figure Saddle The saddle is part of the carriage that fits across the bed slideways and moves along the bed, between the headstock and tailstock. It provides parallel movement of the tool to the axis of the bed. Figure 2.4.4 b - Saddle Cross Slide The cross slide is mounted on top of the saddle and provides a cross movement for the cutting tool (towards or away from the operator). Compound Slide (Compound Rest) The compound slide is mounted on top of the cross slide. As it can be swiveled to any angle, it allows for taper turning Toolpost The toolpost holds the tool holder or the tool directly. There are a few types of toolposts : English (Clamp) type; Rigid too post American (Pillar) type; Standard tool post Turret (4-way) type Quick Release type 5 Figure 2.4.4 e - Toolposts Feed Mechanisms The feed mechanisms consist of: Quick Change Gear Box The quick change gearbox provides easy change of the spindle speed and the speed for the feedshaft and leadscrew. The reason for driving the gearbox from the spindle is that the tool movement per revolution of the spindle must remain constant even if the spindle speed is changed. The gearbox has three functions: To control the speed at which the saddle is driven along the bed when power traversing (parallel operations). To control the speed at which the cross slide moves across the saddle when power cross-traversing (facing operations). To control the speed of the leadscrew when cutting screw threads and thus controlling the lead of the screw being cut (thread cutting operations). Figure 2.4.6 - Feed Mechanism Feedshaft The feedshaft provides automatic power feed to the carriage. Leadscrew The leadscrew provides thread cutting movement to the carriage for thread cutting. 6