Center lathe - Summerhill College

advertisement

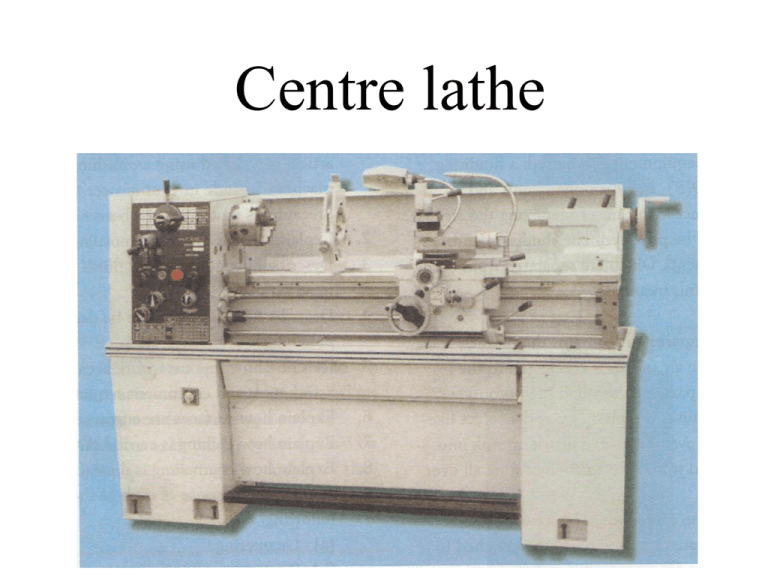

Centre lathe • The Centre Lathe is used to manufacture cylindrical shapes from a range of materials including; steels and plastics. • Components that assemble to make an car engine work have been made using lathes. • The Lathe may be operated by people (manual lathes) or computer controlled lathes (CNC machines) that have been programmed to carry out a particular task. A basic manual centre lathe • The lathe is controlled by a person turning handles on the top slide and cross slide in order to make a part. Lathe Parts • Lathe bed Made from rigid cast Iron Accurately machined slideways Slideways guide carriage & tailstock Headstock on upper end of the lathe bed Lathe parts • Headstock Holds lathe spindle and gears Chuck is fitted to spindle Spindle is hollow for long bars Lathe parts • Tailstock Can be moved along slideways Can be clamped in any location Inside tapered to hold drill chuck Lathe parts • Carriage Moves along bed between tailstock and headstock Saddle – across the lathe Apron – hangs down in front Lathe parts • Cross Slide Fitted on the Saddle Moves cutting tool at right angles to lathe bed Lathe parts • Top Slide (Compound slide) Fitted to top of Cross slide Carries toolpost and cutting tool Can rotate to any angle Is used to turn tapers Lathe parts • Feed shaft Used to move the Carriage automatically • Lead screw Used when screw cutting on the lathe Lathe Parts • Three Jaw Chuck Self centring Holds round and hexagonal work 3 jaws are connected Jaws are stamped 1,2 & 3 and fitted in order Chuck key used to open Lathe parts • Toolpost Fitted on top slide and carries the cutting tool or the cutting tool holder Can adjust the height on some types Can carry 4 different tool holders Lathe parts • Tool holders Used for holding cutting tool bits Available in Right hand, left hand and straight • Cutting Tools Can be High Speed Steel held in tool holders Can be also Ceramic (Tungsten carbide) bits held directly in toolpost Cutting Tool Angle • Clearance angle Ensures only the cutting edge of the tool touches the work Too much clearance causes chatter Cutting tool angle • Rake Angle Allows the chip being cut to flow out Changing the rake changes the power used in cutting and the heat generated Large rake = soft ductile materials Small rake = hard brittle materials Cutting tool angle • Tool bits are held in holders at an angle of about 15° Cutting tools • We can put different shapes on the High speed tool bits to cut different shapes on the workpiece Lathe operations Facing off Parallel Turning Parallel Turning Parallel Turning • The tool moved parallel to the work and cylindrical shapes are formed • Also known as sliding Parallel Turning • The student can Parallel turn the work on the lathe manually or use the automatic traverse option Facing off • The tool is moved at right angles to the work using the cross slide • Flat surfaces are produced Knurling • A knurling tool is used to press a pattern onto a round section. • The pattern is normally used as a grip for a handle. • This provide a grip for the round part e.g. Screwdriver Knurling Parting off • If the student wants to cut off the part they have turned, they can use the hacksaw and a vice or use the parting off tool on the lathe. Setting the tool height • The cutting tool on the lathe must be set to the exact centre of the work-piece • We use the centre of the tailstock to guide us to the correct height Screw-cutting on the lathe • Lathes are also used to cut threads in round bars • These threads take up different profiles e.g iso (60°) ACME etc. • These threads can be seen on bench vices, lathes etc. CNC Lathes • In Industry it is not efficient or profitable to make everyday products by hand. • On a CNC machine it is possible to make hundreds of the same item in a day. • First a design is drawn using design software, then it is processed by the computer and made using the CNC machine. • In industry, CNC machines can be extremely large. LATHE OPERATIONS Producing a Flat Surface Producing a Cylindrical Surface . Taper Turning Radius Turning Attachment Drilling on a Lathe Parting Off / Under Cutting